turewww

www.yijia.com 时间:2021-03-01 阅读:()

EliminatinginterfacialsegregationandembrittlementofbismuthinSnBi/CujointbyalloyingCusubstrateH.

F.

Zou,Q.

K.

ZhangandZ.

F.

Zhang*ShenyangNationalLaboratoryforMaterialsScience,InstituteofMetalResearch,ChineseAcademyofSciences,Shenyang110016,ChinaReceived3March2009;revised3April2009;accepted4April2009Availableonline12April2009ThesegregationofBiattheCu/Cu3SninterfacesoftheSnBi/Cucoupledramaticallydecreasesthiscouple'smechanicalprop-erties.

Here,wedeliberatelyaddAg,Al,SnandZnelementsintotheCusubstratetoeliminatetheinterfacialsegregationandembrittlementoftheSnBi/Cucouple.

ExperimentalresultsconrmedthatthereisalwaysaperfectCu3Sn/CualloyinterfacewithoutBisegregation,andexcellentmechanicalpropertiesarethusmaintained.

Themostimportantndingisthattheinterfacialembrit-tlementofSnBi/Cualloyjointswassuccessfullyeliminatedevenafterprolongedaging.

2009ActaMaterialiaInc.

PublishedbyElsevierLtd.

Allrightsreserved.

Keywords:Biinterfacialsegregation;Embrittlement;Pb-freesolder;Interfacialstrength;SolderingSolderingisaveryimportantprocedureintheelectronicpackagingeld[1].

Lead-freesolders,thoughpromising,presenttwoseriousdefects:(i)theirmeltingpointsaremuchhigherthanthoseoftraditionalSnPbsolders[1];(ii)BisegregationattheCu/Cu3SninterfacealwaysoccurswiththeSnBi/Cucouple[2].

Thesegrega-tionofimpuritiesalwaysseriouslydeterioratesthephys-icalandmechanicalpropertiesofthematerial[3,4],asdoesBisegregation.

Thisiswhy,intheelectronicpack-agingeld,useoflead-freesoldersisstillnotwidespreadeventhoughlegislationtolimittheuseofSnPbhasbeenextantinmanycountriesformanyyears[1].

Inordertoextendtheapplicationoflead-freesolder,onemust:(i)decreaseitsmeltingpoint;or(ii)restricttheBisegregationattheSnBi/Cuinterface.

Researchre-sultsconcerningtheformerarenotpromising[1,5].

Aboutthelatter,LiuandShang[6]andZhuetal.

[7]havetriedtoemployelectrodepositionofAgorNithinlmsontotheCusubstratetosuccessfullypreventtheinterfacialembrittlementofSnBi/Cuinterconnectsevenafterlongagingtimes.

Butthisapproachcannotbeusedoncertaininterfaceswhereitisdicultorimpossibletoelectricallydepositthinlmsontheinterfaces.

Historically,thepoorductilityofpolycrystallineNi3Alhasbeensuccessfulim-provedbyaddingB[8],andthisapproachhasinfusednewlifeintotheresearchandapplicationofintermetallicsinthepasttwodecades[9–12].

Inthiscontext,therefore,thedeliberateadditionofAg,Al,Sn,ZnelementsintoCusubstratewasexpectedtorestraininterfacialBisegre-gation.

AmpleexperimentalevidencehasindicatedthatalloyingCusubstratecansuccessfullyeliminateBisegre-gationattheSnBi/Cuinterface,leadingtotheimprove-mentofinterfacialmechanicalproperties.

Therefore,intheelectronicpackagingeld,thisstrategymightenableSnBisoldertobewidelyusedandinthefuturereplaceSnPbsolder.

Moreimportantly,themethodprovidesanewvisualizationtounderstandandeliminateotherinter-facialsegregation(suchasP,SorSbinsteelsandBiinpoly-Cu).

Inthisstudy,pureCuandCualloys(Cu–2.

3Al,Cu–2.

5Ag,Cu–18.

7Ag,Cu–10ZnandCu–3Sn)wereusedassubstrates.

EutecticSn–58wt.

%Bialloywasemployedassolder.

Cu,CualloysandSnBialloywerecutandgroundwith800#,1000#,2000#SiCpaperandthencarefullypolishedwiththe2.

5and1.

5lmpol-ishingpastes.

Allthepreparedsampleswerekeptinanovenataconstanttemperatureof200°Cfor6min.

Onegroupofsampleswasisothermallyagedat120°Cfordierenttimestorevealtheinterfacialmicrostruc-tureoftheSnBicouples.

SometensilesamplesofSnBi/CuandSnBi/Cu–Xjoints(X=Al,Ag,ZnandSn)wereisothermallyagedat120°Cfordierentnum-bersofdaysinordertoinvestigatetheinterfacialmechanicalpropertiesofthejoints.

Tensiletestswere1359-6462/$-seefrontmatter2009ActaMaterialiaInc.

PublishedbyElsevierLtd.

Allrightsreserved.

doi:10.

1016/j.

scriptamat.

2009.

04.

009*Correspondingauthor.

Tel.

:+862423971043;e-mail:zhfzhang@imr.

ac.

cnAvailableonlineatwww.

sciencedirect.

comScriptaMaterialia61(2009)308–311www.

elsevier.

com/locate/scriptamatperformedwithanInstron8871testingmachineatanaveragestrainrateofabout5105s1atroomtem-peratureinair.

Thefracturesurfaceswereobservedbyscanningelectronmicroscopy(SEM)torevealtheirdeformationandfracturemorphologies.

Figure1showstheclose-upbackscatteredelectronSEMimagesoftheinterfacesintheSnBi/CuandSnBi/Cu–X(X=Ag,Al,SnandZn)couplesat120°Cfordierentperiods.

DiscontinuousBiparticlescouldbeeasilyobservedattheSnBi/Cuinterfacewhenthesamplewasagedat120°Cfor12.

5days,asindi-catedbytheredcirclesinFigure1a.

ThisimpliesthatBisegregationwouldtakeplaceattheSnBi/Cuinterfaceafterprolongedaging,ashasbeendetectedinpreviousstudies[2,6,7].

LiuandShang[6],however,consideredthattheBiatomswouldmainlyappearintheformofamonolayerattheCu/Cu3Sninterface,whichisdier-entfromthecurrentexperimentalresults.

Furthermore,somevoidscanbeobservedneartheBiparticles,asdis-playedbythewhitearrowinFigure1a.

SincetheBisegregationattheCu/Cu3SninterfacecanaectthenucleationandgrowthofKirkendallvoidssimultaneously,thefreeenergybarrierforthevoidnucleationcanbeexpressedas[13]:DG4c3fVr2;1wherer,c,fVarethelocalstress,interfaceenergyandageometricalfactorofthevoid,respectively.

Obviously,rincludesthethermalstressandotherresidualstressformedduringtheagingprocedure.

AccordingtotheGibbsisotherm,theinterfacialenergywouldreducebe-causeoftheBisegregationattheCu/Cu3Sninterface.

Inaddition,thethermalstresswouldincreasewithagingtime.

BasedonEq.

(1),theDGwoulddecreaseastheva-lueofcreduces,andincreasethelocalstressr.

There-fore,asteady-statenucleationrateofvoidswouldoccurduringtheagingprocedure.

Thegrowthofvoidswouldacceleratebecausetheatomsonthevoidsurfacediusetothesolder.

Asaresult,ahighconcentrationofvoidswouldformneartheinterfaceandfurthersupportthegrowthofvoidsduetotheKirkendalleect[13,14].

Incontrast,BiparticlesandvoidswerenotobservedattheSnBi/CuSninterfacewhenthecouplewasagedat120°Cevenfor17days,asdisplayedinFigure1b.

ThisindicatedthatBisegregationwouldberestrainedattheSnBi/CuSninterfacesevenafteralongeragingtime.

Basedontheseexperimentalresults,theinterfacesofSnBi/CuAgcoupleswereinvestigated.

AneCu3Sn/CuAginterfacewasobservedirrespectiveofwhethertheAgconcentrationwashigh(18.

7%)orlow(2.

5%)fortheCuAgsubstrate,asillustratedbytheblackarrowsinFigure1candd.

ThecurrentexperimentalresultsfurtherconrmthatBisegregationwasalsoinhibitedintheSnBi/CuAgcouples.

Inaddition,Cu–2.

3AlandCu–10ZnalloyswereusedtorevealwhetherthesecaninhibitBisegregation.

TheseresultsdemonstratethatBisegregationdidnotoccurattheinterfacesoftheSnBi/CuAlandSnBi/CuZncouples,asillustratedbytheblackarrowsinFigure1eandf.

Averyimportantquestion,however,needstobecon-sidered:wherearetheBiatomsfortheseSnBi/Cu–XcouplesItisassumedthattheBiatomsfromtheSnBisoldershoulddiuseintotheCualloytoformamorestablealloysystemcomparedwiththeBisegregationattheCu/Cu3Sninterface.

Inordertoconrmsuchassumption,anacceleratedexperimentwasdesigned.

TheCu–18.

7AgalloywascompletelysaturatedinliquidBiat500°Cfor6h.

ItisclearlyseenthatsomeAgintheCu–18.

7AgalloywasalmostreplacedbyBi,asillus-tratedinFigure2.

ThisindicatesthatthereplacementofAgatomsbyBiatomsmakestheCu–Agsystemmoresta-blecomparedwiththebinaryCu–Agalloy.

IthasbeenprovedpreviouslythattheAg–Cu–BialloyformstheAg5-Cu0.

5Bi94.

5(at.

%)eutecticphase[15].

Thus,theexistenceofAginCu–AgalloyassiststhediusionofBiatomsintoCu–Agalloy,formingamorestableternaryCuAgBialloyduringaging.

However,thediusionofBiatomsintotheFigure1.

Interfacialmicrostructuresofsamplesagedat120°C:(a)SnBi/Cufor12.

5days;(b)SnBi/Cu–3Snfor17days;(c)SnBi/Cu–2.

5Agfor12.

5days;(d)SnBi/Cu–18.

7Agfor12.

5days;(e)SnBi/Cu–2.

3Alfor17days;and(f)SnBi/Cu–10Znfor17days.

Figure2.

MicrostructureofCu–18.

7AgalloyaftersaturatinginliquidBifor6h.

H.

F.

Zouetal.

/ScriptaMaterialia61(2009)308–311309pureCusubstrateisverydicultbecausetheCu–Bisys-temiscompletelyimmiscible[16–18].

SinceBisegregationhasbeeneliminated,itisneces-sarytomeasurethemechanicalpropertiesoftheSnBi/Cu–Xjointsafteragingfordierentperiods.

Figure3ashowsthetensilestress–straincurvesoftheSnBi/CuandSnBi/Cu–18.

7Agjoints.

TheseresultsdemonstratethatdierentmechanicalpropertiesareobservedfortheSnBi/CuandSnBi/CuAgjoints.

ThetensilestrengthoftheSnBi/Cuisstronglyaectedbytheagingtime(seecurvesAandC).

Figure3bshowsthatthetensilestrengthofSnBi/Cudramaticallydecreasesfromabout155MPaforas-reowedto31MPaafteragingat120°Cfor8.

25days.

WhentheSnBi/Cujointswereagedat120°Cfor13.

5days,thejointswereveryeasytobreakevenduringgrinding,soitstensilestrengthisdeemedtobeapproximatelyzero.

However,thetensilestress–straincurveoftheSnBi/Cu–18.

7Agjointshowsnoobviouschange(seecurvesBandDinFig.

3a).

Thedecreaseinthetensilestrengthisonlyabout10MPawhentheSnBi/Cu–18.

7Agjointsampleswereagedat120°Cfor11days.

SincealloyingCusubstratecansignicantlyimprovethejointstrength,otherSnBi/Cu–Xjointswerealsoinvestigatedinourexperiment.

Figure3bshowsthedependenceoftensilestrengthonagingtimeforalltheSnBi/Cu–X(X=Al,Ag,SnandZn)joints.

Itcanbeseenthatthetensilestrengthdecreasesonlyslightlywithincreasingagingtimeforallthejoints,whichissignicantlydierentfromtheSnBi/Cujoints,asillustratedbythepanelinFigure3b.

Ifonlythemechanicalpropertiesareconsid-ered,theCu–Agalloysarethebestsubstrate.

However,thegrowthkineticsofintermetallicscompounds(IMCs)andthecostoftheproductneedtobeconsidered.

ExperimentalresultshaveconrmedthattheCu3SnwouldnotformattheinterfaceandthegrowthrateofIMCistheslowestfortheCu–Znalloy(H.

F.

Zou,unpublished).

Inaddition,thepriceofZnisthelowestamongthesemetals[1];therefore,theCu–Znalloycanberecommendedasapotentialsubstratefortheapplica-tionoftheSnBi/Cu–Xcouplejoints.

Figure4showsthefracturemorphologiesofthejoints.

ManysoldersandIMCswereobservedonthefracturesurfacesoftheas-reowedSnBi/Cujoints,whichissimilartootherlead-freesolderjoints[19],asdisplayedinFigure4a.

TheinsetpictureofFigure4aindicates,basedonthecross-sectionoffracturemor-phology,thattheIMClayeradheredtoCusubstrate.

Comparedwiththeas-reowedSnBi/Cujoint,thefrac-turemorphologyoftheSnBi/Cujointagedfor8.

25daysisremarkablydierentfromthatoftheas-reowedsam-ples,asdisplayedinFigure4b.

MostoftheCusubstratewasexposedonthefracturemorphology,asillustratedbytheleftinsetdiagramofFigure4b.

TheCu–SnIMClayersadhereattheSnBisolder,butnotattheCusubstrate,asdemonstratedbytherightinsetdiagramofFigure4b.

Theseresultsindicatethatthefractureoc-cursalongtheCu/Cu–SnIMCinterfaceratherthanalongtheCu–SnIMC/solderinterface,leadingtotheinterfacialembrittlement.

ConcerningthefracturemodeoftheSnBi/Cujointagedat120°Cover8.

25days,LiuandShangpostulatedthatthedierenceinsizebetweenCuandBiatomsplaysasignicantroleintheembrittlementasinthecaseofBi–CualloybecausetheBiatomislargerthantheSnandCuatoms[2].

ThepreviousresultsreportedthatthesizeeectcausesBiprecipitationandvoidformationintheCumatrixfortheCu–Bialloy.

BiparticlesandvoidswerefoundonthefracturesurfaceoftheCu–Bialloybecauseofthedierentthermalexpansioncoe-cientsandtheweakadhesionbetweentheCumatrixandBiprecipitates[20].

ThisiscompletelydierentfromthesituationfoundinSnBi/Cujoints.

Thus,theembrit-tlementmechanismofSnBi/CujointsshouldbedierentfromthatoftheCu–Bialloysystem.

Asmentionedabove,BisegregationacceleratestheformationofvoidsinSnBi/Cujoints.

Furthermore,thevoidswouldisolatetheCu/Cu3SninterfaceandthendramaticallydecreasetheinterfacialbondingstrengthoftheSnBi/Cujoint,asconrmedinFigure1aandtheleftinsetdiagraminFigure4b.

However,thetensilestrengthsofallSnBi/Cu–Xjointsdecreaseonlyslightlywithincreasingagingtime,asillustratedbythepanelinFigure3b.

AlljointsbrokealongtheSnBi/Cu6Sn5interface,andsomeSnBisolderwasobservedtoadhereonthefracturesurfacefortheas-reowedSnBi/Cu–18.

7Agcouples,asdisplayedinFigure4c.

ThefracturemorphologiesoftheSnBi/Cu–18.

7Agcoupleshownoobviouschangealthoughtheagingtimeincreasesupto11days,asshownbyFigure3.

(a)Tensilestress–straincurvesforSnBijoints.

AandCrepresentedthetensilecurvesofSnBi/Cujointsagedat120°Cfor0,8.

25days,respectively;BandDrepresentedthetensilecurvesofSnBi/Cu18.

7Agjointsagedat120°Cfor0,11days,respectively.

(b)ThedependenceoftensilestrengthonagingtimeforalltheSnBi/CuandSnBi/Cu–Xjoints.

310H.

F.

Zouetal.

/ScriptaMaterialia61(2009)308–311therightinsetdiagraminFigure4c.

ThemainreasonisthatthevoidwouldnotformattheSnBi/Cu–Xinter-facewithoutBisegregation.

TheleftinsetdiagraminFigure4cdemonstratesthatthecrackrstnucleatedalongtheSnBi/Cu–SnIMCinterface.

IrrespectiveofwhethertheSnBi/Cu–2.

3Aljointswereas-reowedoraged,someSnBisolderstillclungtothesubstrate,asdisplayedbythewhitearrowsinFigure4d.

ForotherCualloysubstrates,thefracturemodewasunchangedforbothas-reowedandagedstates.

Theseresultsfur-therconrmtheeliminationofBisegregationandtheinterfacialembrittlementinSnBi/Cu–Xjointsonthemi-cro-scale.

Insummary,alloyingCusubstratecanessentiallyeliminatetheinterfacialembrittlementanddramaticallyimprovethemechanicalpropertiesoftheSnBi/Cusys-temafterprolongedaging.

ThisstrategynotonlypavesthenewwayforthewidescalefutureuseofSnBisolderintheelectronicpackagingeldinthefuture,butalsoprovidesanewmethodtoanalyzeinterfacialsegrega-tioninsystemssuchasBi-dopedCu.

TheauthorswouldliketoacknowledgeQ.

Q.

Duan,P.

Zhang,Y.

Z.

Tian,X.

H.

An,S.

Qu,H.

H.

Su,L.

X.

ZhangandW.

Gao.

Thisworkwasnanciallysup-portedbyNationalBasicResearchProgramofChinaunderGrantNo.

2004CB619306,theNationalOut-standingYoungScientistFoundationunderGrantNo.

50625103.

[1]M.

Abtew,G.

Selvaduray,Mater.

Sci.

Eng.

R27(2000)95.

[2]P.

L.

Liu,J.

K.

Shang,J.

Mater.

Res.

16(2001)1651.

[3]A.

Y.

Lozovoi,A.

T.

Paxton,M.

W.

Finnis,Phys.

Rev.

B74(2006)155416.

[4]V.

J.

Keast,J.

Bruley,P.

Rez,J.

M.

Maclaren,D.

B.

Williams,ActaMater.

46(1998)481.

[5]C.

M.

L.

Wu,D.

Q.

C.

Yu,M.

T.

Law,L.

Wang,J.

Mater.

Res.

31(2002)3146.

[6]P.

L.

Liu,J.

K.

Shang,J.

Mater.

Res.

20(2005)818.

[7]Q.

S.

Zhu,Z.

F.

Zhang,Z.

G.

Wang,J.

K.

Shang,J.

Mater.

Res.

23(2008)78.

[8]K.

Aoki,O.

Izumi,J.

Jpn.

Inst.

Met.

43(1979)1190.

[9]D.

A.

Muller,S.

Subramanian,P.

E.

Batson,S.

L.

Sass,J.

Silcox,Phys.

Rev.

Lett.

75(1995)4744.

[10]C.

T.

Liu,E.

H.

Lee,E.

P.

George,A.

J.

Duncan,Scr.

Metall.

Mater.

30(1994)387.

[11]G.

K.

Dey,A.

Arya,J.

A.

Sekhar,J.

Mater.

Res.

15(2000)63.

[12]D.

A.

Muller,S.

Subramanian,P.

E.

Batson,J.

Silcox,S.

L.

Sass,ActaMater.

44(1996)1637.

[13]H.

Riedel,FractureatHighTemperatures,SpringerVerlag,Berlin,1987.

[14]J.

Y.

Kim,J.

Yu,Appl.

Phys.

Lett.

92(2008)092109.

[15]S.

Q.

Liu,W.

Q.

Sun,ActaMeter.

Sin.

24(1988)376.

[16]G.

Duscher,M.

F.

Chisholm,U.

Alber,M.

Ru¨hle,Nat.

Mater.

3(2004)621.

[17]R.

Schweinfest,A.

T.

Paxton,M.

W.

Finnis,Nature432(2004)1008.

[18]U.

Alber,H.

Mue`llejans,M.

Rue`hle,ActaMater.

47(1999)4047.

[19]F.

Ren,J.

W.

Nah,K.

N.

Tu,B.

S.

Xiong,L.

H.

Xu,J.

H.

L.

Pang,Appl.

Phys.

Lett.

89(2006)141914.

[20]D.

T.

L.

VanAgterveld,G.

Palasantzas,J.

T.

M.

DeHosson,ActaMater.

48(2000)1995.

Figure4.

FracturesurfacesofSnBi/Cu,SnBi/Cu–18.

7AgandCu–2.

3Al/SnBijoints.

(a)SnBi/Cujointas-reowed;(b)agedat120°Cfor8.

25days—theleftinsetdisplaysamagniedmorphology,therightinsetdisplaysthecross-sectionmorphology;(c)as-reowedSnBi/Cu–18.

7Agjointandthejointagedfor11days;and(d)as-reowedSnBi/Cu–2.

3Aljointandthejointagedfor17days.

H.

F.

Zouetal.

/ScriptaMaterialia61(2009)308–311311

F.

Zou,Q.

K.

ZhangandZ.

F.

Zhang*ShenyangNationalLaboratoryforMaterialsScience,InstituteofMetalResearch,ChineseAcademyofSciences,Shenyang110016,ChinaReceived3March2009;revised3April2009;accepted4April2009Availableonline12April2009ThesegregationofBiattheCu/Cu3SninterfacesoftheSnBi/Cucoupledramaticallydecreasesthiscouple'smechanicalprop-erties.

Here,wedeliberatelyaddAg,Al,SnandZnelementsintotheCusubstratetoeliminatetheinterfacialsegregationandembrittlementoftheSnBi/Cucouple.

ExperimentalresultsconrmedthatthereisalwaysaperfectCu3Sn/CualloyinterfacewithoutBisegregation,andexcellentmechanicalpropertiesarethusmaintained.

Themostimportantndingisthattheinterfacialembrit-tlementofSnBi/Cualloyjointswassuccessfullyeliminatedevenafterprolongedaging.

2009ActaMaterialiaInc.

PublishedbyElsevierLtd.

Allrightsreserved.

Keywords:Biinterfacialsegregation;Embrittlement;Pb-freesolder;Interfacialstrength;SolderingSolderingisaveryimportantprocedureintheelectronicpackagingeld[1].

Lead-freesolders,thoughpromising,presenttwoseriousdefects:(i)theirmeltingpointsaremuchhigherthanthoseoftraditionalSnPbsolders[1];(ii)BisegregationattheCu/Cu3SninterfacealwaysoccurswiththeSnBi/Cucouple[2].

Thesegrega-tionofimpuritiesalwaysseriouslydeterioratesthephys-icalandmechanicalpropertiesofthematerial[3,4],asdoesBisegregation.

Thisiswhy,intheelectronicpack-agingeld,useoflead-freesoldersisstillnotwidespreadeventhoughlegislationtolimittheuseofSnPbhasbeenextantinmanycountriesformanyyears[1].

Inordertoextendtheapplicationoflead-freesolder,onemust:(i)decreaseitsmeltingpoint;or(ii)restricttheBisegregationattheSnBi/Cuinterface.

Researchre-sultsconcerningtheformerarenotpromising[1,5].

Aboutthelatter,LiuandShang[6]andZhuetal.

[7]havetriedtoemployelectrodepositionofAgorNithinlmsontotheCusubstratetosuccessfullypreventtheinterfacialembrittlementofSnBi/Cuinterconnectsevenafterlongagingtimes.

Butthisapproachcannotbeusedoncertaininterfaceswhereitisdicultorimpossibletoelectricallydepositthinlmsontheinterfaces.

Historically,thepoorductilityofpolycrystallineNi3Alhasbeensuccessfulim-provedbyaddingB[8],andthisapproachhasinfusednewlifeintotheresearchandapplicationofintermetallicsinthepasttwodecades[9–12].

Inthiscontext,therefore,thedeliberateadditionofAg,Al,Sn,ZnelementsintoCusubstratewasexpectedtorestraininterfacialBisegre-gation.

AmpleexperimentalevidencehasindicatedthatalloyingCusubstratecansuccessfullyeliminateBisegre-gationattheSnBi/Cuinterface,leadingtotheimprove-mentofinterfacialmechanicalproperties.

Therefore,intheelectronicpackagingeld,thisstrategymightenableSnBisoldertobewidelyusedandinthefuturereplaceSnPbsolder.

Moreimportantly,themethodprovidesanewvisualizationtounderstandandeliminateotherinter-facialsegregation(suchasP,SorSbinsteelsandBiinpoly-Cu).

Inthisstudy,pureCuandCualloys(Cu–2.

3Al,Cu–2.

5Ag,Cu–18.

7Ag,Cu–10ZnandCu–3Sn)wereusedassubstrates.

EutecticSn–58wt.

%Bialloywasemployedassolder.

Cu,CualloysandSnBialloywerecutandgroundwith800#,1000#,2000#SiCpaperandthencarefullypolishedwiththe2.

5and1.

5lmpol-ishingpastes.

Allthepreparedsampleswerekeptinanovenataconstanttemperatureof200°Cfor6min.

Onegroupofsampleswasisothermallyagedat120°Cfordierenttimestorevealtheinterfacialmicrostruc-tureoftheSnBicouples.

SometensilesamplesofSnBi/CuandSnBi/Cu–Xjoints(X=Al,Ag,ZnandSn)wereisothermallyagedat120°Cfordierentnum-bersofdaysinordertoinvestigatetheinterfacialmechanicalpropertiesofthejoints.

Tensiletestswere1359-6462/$-seefrontmatter2009ActaMaterialiaInc.

PublishedbyElsevierLtd.

Allrightsreserved.

doi:10.

1016/j.

scriptamat.

2009.

04.

009*Correspondingauthor.

Tel.

:+862423971043;e-mail:zhfzhang@imr.

ac.

cnAvailableonlineatwww.

sciencedirect.

comScriptaMaterialia61(2009)308–311www.

elsevier.

com/locate/scriptamatperformedwithanInstron8871testingmachineatanaveragestrainrateofabout5105s1atroomtem-peratureinair.

Thefracturesurfaceswereobservedbyscanningelectronmicroscopy(SEM)torevealtheirdeformationandfracturemorphologies.

Figure1showstheclose-upbackscatteredelectronSEMimagesoftheinterfacesintheSnBi/CuandSnBi/Cu–X(X=Ag,Al,SnandZn)couplesat120°Cfordierentperiods.

DiscontinuousBiparticlescouldbeeasilyobservedattheSnBi/Cuinterfacewhenthesamplewasagedat120°Cfor12.

5days,asindi-catedbytheredcirclesinFigure1a.

ThisimpliesthatBisegregationwouldtakeplaceattheSnBi/Cuinterfaceafterprolongedaging,ashasbeendetectedinpreviousstudies[2,6,7].

LiuandShang[6],however,consideredthattheBiatomswouldmainlyappearintheformofamonolayerattheCu/Cu3Sninterface,whichisdier-entfromthecurrentexperimentalresults.

Furthermore,somevoidscanbeobservedneartheBiparticles,asdis-playedbythewhitearrowinFigure1a.

SincetheBisegregationattheCu/Cu3SninterfacecanaectthenucleationandgrowthofKirkendallvoidssimultaneously,thefreeenergybarrierforthevoidnucleationcanbeexpressedas[13]:DG4c3fVr2;1wherer,c,fVarethelocalstress,interfaceenergyandageometricalfactorofthevoid,respectively.

Obviously,rincludesthethermalstressandotherresidualstressformedduringtheagingprocedure.

AccordingtotheGibbsisotherm,theinterfacialenergywouldreducebe-causeoftheBisegregationattheCu/Cu3Sninterface.

Inaddition,thethermalstresswouldincreasewithagingtime.

BasedonEq.

(1),theDGwoulddecreaseastheva-lueofcreduces,andincreasethelocalstressr.

There-fore,asteady-statenucleationrateofvoidswouldoccurduringtheagingprocedure.

Thegrowthofvoidswouldacceleratebecausetheatomsonthevoidsurfacediusetothesolder.

Asaresult,ahighconcentrationofvoidswouldformneartheinterfaceandfurthersupportthegrowthofvoidsduetotheKirkendalleect[13,14].

Incontrast,BiparticlesandvoidswerenotobservedattheSnBi/CuSninterfacewhenthecouplewasagedat120°Cevenfor17days,asdisplayedinFigure1b.

ThisindicatedthatBisegregationwouldberestrainedattheSnBi/CuSninterfacesevenafteralongeragingtime.

Basedontheseexperimentalresults,theinterfacesofSnBi/CuAgcoupleswereinvestigated.

AneCu3Sn/CuAginterfacewasobservedirrespectiveofwhethertheAgconcentrationwashigh(18.

7%)orlow(2.

5%)fortheCuAgsubstrate,asillustratedbytheblackarrowsinFigure1candd.

ThecurrentexperimentalresultsfurtherconrmthatBisegregationwasalsoinhibitedintheSnBi/CuAgcouples.

Inaddition,Cu–2.

3AlandCu–10ZnalloyswereusedtorevealwhetherthesecaninhibitBisegregation.

TheseresultsdemonstratethatBisegregationdidnotoccurattheinterfacesoftheSnBi/CuAlandSnBi/CuZncouples,asillustratedbytheblackarrowsinFigure1eandf.

Averyimportantquestion,however,needstobecon-sidered:wherearetheBiatomsfortheseSnBi/Cu–XcouplesItisassumedthattheBiatomsfromtheSnBisoldershoulddiuseintotheCualloytoformamorestablealloysystemcomparedwiththeBisegregationattheCu/Cu3Sninterface.

Inordertoconrmsuchassumption,anacceleratedexperimentwasdesigned.

TheCu–18.

7AgalloywascompletelysaturatedinliquidBiat500°Cfor6h.

ItisclearlyseenthatsomeAgintheCu–18.

7AgalloywasalmostreplacedbyBi,asillus-tratedinFigure2.

ThisindicatesthatthereplacementofAgatomsbyBiatomsmakestheCu–Agsystemmoresta-blecomparedwiththebinaryCu–Agalloy.

IthasbeenprovedpreviouslythattheAg–Cu–BialloyformstheAg5-Cu0.

5Bi94.

5(at.

%)eutecticphase[15].

Thus,theexistenceofAginCu–AgalloyassiststhediusionofBiatomsintoCu–Agalloy,formingamorestableternaryCuAgBialloyduringaging.

However,thediusionofBiatomsintotheFigure1.

Interfacialmicrostructuresofsamplesagedat120°C:(a)SnBi/Cufor12.

5days;(b)SnBi/Cu–3Snfor17days;(c)SnBi/Cu–2.

5Agfor12.

5days;(d)SnBi/Cu–18.

7Agfor12.

5days;(e)SnBi/Cu–2.

3Alfor17days;and(f)SnBi/Cu–10Znfor17days.

Figure2.

MicrostructureofCu–18.

7AgalloyaftersaturatinginliquidBifor6h.

H.

F.

Zouetal.

/ScriptaMaterialia61(2009)308–311309pureCusubstrateisverydicultbecausetheCu–Bisys-temiscompletelyimmiscible[16–18].

SinceBisegregationhasbeeneliminated,itisneces-sarytomeasurethemechanicalpropertiesoftheSnBi/Cu–Xjointsafteragingfordierentperiods.

Figure3ashowsthetensilestress–straincurvesoftheSnBi/CuandSnBi/Cu–18.

7Agjoints.

TheseresultsdemonstratethatdierentmechanicalpropertiesareobservedfortheSnBi/CuandSnBi/CuAgjoints.

ThetensilestrengthoftheSnBi/Cuisstronglyaectedbytheagingtime(seecurvesAandC).

Figure3bshowsthatthetensilestrengthofSnBi/Cudramaticallydecreasesfromabout155MPaforas-reowedto31MPaafteragingat120°Cfor8.

25days.

WhentheSnBi/Cujointswereagedat120°Cfor13.

5days,thejointswereveryeasytobreakevenduringgrinding,soitstensilestrengthisdeemedtobeapproximatelyzero.

However,thetensilestress–straincurveoftheSnBi/Cu–18.

7Agjointshowsnoobviouschange(seecurvesBandDinFig.

3a).

Thedecreaseinthetensilestrengthisonlyabout10MPawhentheSnBi/Cu–18.

7Agjointsampleswereagedat120°Cfor11days.

SincealloyingCusubstratecansignicantlyimprovethejointstrength,otherSnBi/Cu–Xjointswerealsoinvestigatedinourexperiment.

Figure3bshowsthedependenceoftensilestrengthonagingtimeforalltheSnBi/Cu–X(X=Al,Ag,SnandZn)joints.

Itcanbeseenthatthetensilestrengthdecreasesonlyslightlywithincreasingagingtimeforallthejoints,whichissignicantlydierentfromtheSnBi/Cujoints,asillustratedbythepanelinFigure3b.

Ifonlythemechanicalpropertiesareconsid-ered,theCu–Agalloysarethebestsubstrate.

However,thegrowthkineticsofintermetallicscompounds(IMCs)andthecostoftheproductneedtobeconsidered.

ExperimentalresultshaveconrmedthattheCu3SnwouldnotformattheinterfaceandthegrowthrateofIMCistheslowestfortheCu–Znalloy(H.

F.

Zou,unpublished).

Inaddition,thepriceofZnisthelowestamongthesemetals[1];therefore,theCu–Znalloycanberecommendedasapotentialsubstratefortheapplica-tionoftheSnBi/Cu–Xcouplejoints.

Figure4showsthefracturemorphologiesofthejoints.

ManysoldersandIMCswereobservedonthefracturesurfacesoftheas-reowedSnBi/Cujoints,whichissimilartootherlead-freesolderjoints[19],asdisplayedinFigure4a.

TheinsetpictureofFigure4aindicates,basedonthecross-sectionoffracturemor-phology,thattheIMClayeradheredtoCusubstrate.

Comparedwiththeas-reowedSnBi/Cujoint,thefrac-turemorphologyoftheSnBi/Cujointagedfor8.

25daysisremarkablydierentfromthatoftheas-reowedsam-ples,asdisplayedinFigure4b.

MostoftheCusubstratewasexposedonthefracturemorphology,asillustratedbytheleftinsetdiagramofFigure4b.

TheCu–SnIMClayersadhereattheSnBisolder,butnotattheCusubstrate,asdemonstratedbytherightinsetdiagramofFigure4b.

Theseresultsindicatethatthefractureoc-cursalongtheCu/Cu–SnIMCinterfaceratherthanalongtheCu–SnIMC/solderinterface,leadingtotheinterfacialembrittlement.

ConcerningthefracturemodeoftheSnBi/Cujointagedat120°Cover8.

25days,LiuandShangpostulatedthatthedierenceinsizebetweenCuandBiatomsplaysasignicantroleintheembrittlementasinthecaseofBi–CualloybecausetheBiatomislargerthantheSnandCuatoms[2].

ThepreviousresultsreportedthatthesizeeectcausesBiprecipitationandvoidformationintheCumatrixfortheCu–Bialloy.

BiparticlesandvoidswerefoundonthefracturesurfaceoftheCu–Bialloybecauseofthedierentthermalexpansioncoe-cientsandtheweakadhesionbetweentheCumatrixandBiprecipitates[20].

ThisiscompletelydierentfromthesituationfoundinSnBi/Cujoints.

Thus,theembrit-tlementmechanismofSnBi/CujointsshouldbedierentfromthatoftheCu–Bialloysystem.

Asmentionedabove,BisegregationacceleratestheformationofvoidsinSnBi/Cujoints.

Furthermore,thevoidswouldisolatetheCu/Cu3SninterfaceandthendramaticallydecreasetheinterfacialbondingstrengthoftheSnBi/Cujoint,asconrmedinFigure1aandtheleftinsetdiagraminFigure4b.

However,thetensilestrengthsofallSnBi/Cu–Xjointsdecreaseonlyslightlywithincreasingagingtime,asillustratedbythepanelinFigure3b.

AlljointsbrokealongtheSnBi/Cu6Sn5interface,andsomeSnBisolderwasobservedtoadhereonthefracturesurfacefortheas-reowedSnBi/Cu–18.

7Agcouples,asdisplayedinFigure4c.

ThefracturemorphologiesoftheSnBi/Cu–18.

7Agcoupleshownoobviouschangealthoughtheagingtimeincreasesupto11days,asshownbyFigure3.

(a)Tensilestress–straincurvesforSnBijoints.

AandCrepresentedthetensilecurvesofSnBi/Cujointsagedat120°Cfor0,8.

25days,respectively;BandDrepresentedthetensilecurvesofSnBi/Cu18.

7Agjointsagedat120°Cfor0,11days,respectively.

(b)ThedependenceoftensilestrengthonagingtimeforalltheSnBi/CuandSnBi/Cu–Xjoints.

310H.

F.

Zouetal.

/ScriptaMaterialia61(2009)308–311therightinsetdiagraminFigure4c.

ThemainreasonisthatthevoidwouldnotformattheSnBi/Cu–Xinter-facewithoutBisegregation.

TheleftinsetdiagraminFigure4cdemonstratesthatthecrackrstnucleatedalongtheSnBi/Cu–SnIMCinterface.

IrrespectiveofwhethertheSnBi/Cu–2.

3Aljointswereas-reowedoraged,someSnBisolderstillclungtothesubstrate,asdisplayedbythewhitearrowsinFigure4d.

ForotherCualloysubstrates,thefracturemodewasunchangedforbothas-reowedandagedstates.

Theseresultsfur-therconrmtheeliminationofBisegregationandtheinterfacialembrittlementinSnBi/Cu–Xjointsonthemi-cro-scale.

Insummary,alloyingCusubstratecanessentiallyeliminatetheinterfacialembrittlementanddramaticallyimprovethemechanicalpropertiesoftheSnBi/Cusys-temafterprolongedaging.

ThisstrategynotonlypavesthenewwayforthewidescalefutureuseofSnBisolderintheelectronicpackagingeldinthefuture,butalsoprovidesanewmethodtoanalyzeinterfacialsegrega-tioninsystemssuchasBi-dopedCu.

TheauthorswouldliketoacknowledgeQ.

Q.

Duan,P.

Zhang,Y.

Z.

Tian,X.

H.

An,S.

Qu,H.

H.

Su,L.

X.

ZhangandW.

Gao.

Thisworkwasnanciallysup-portedbyNationalBasicResearchProgramofChinaunderGrantNo.

2004CB619306,theNationalOut-standingYoungScientistFoundationunderGrantNo.

50625103.

[1]M.

Abtew,G.

Selvaduray,Mater.

Sci.

Eng.

R27(2000)95.

[2]P.

L.

Liu,J.

K.

Shang,J.

Mater.

Res.

16(2001)1651.

[3]A.

Y.

Lozovoi,A.

T.

Paxton,M.

W.

Finnis,Phys.

Rev.

B74(2006)155416.

[4]V.

J.

Keast,J.

Bruley,P.

Rez,J.

M.

Maclaren,D.

B.

Williams,ActaMater.

46(1998)481.

[5]C.

M.

L.

Wu,D.

Q.

C.

Yu,M.

T.

Law,L.

Wang,J.

Mater.

Res.

31(2002)3146.

[6]P.

L.

Liu,J.

K.

Shang,J.

Mater.

Res.

20(2005)818.

[7]Q.

S.

Zhu,Z.

F.

Zhang,Z.

G.

Wang,J.

K.

Shang,J.

Mater.

Res.

23(2008)78.

[8]K.

Aoki,O.

Izumi,J.

Jpn.

Inst.

Met.

43(1979)1190.

[9]D.

A.

Muller,S.

Subramanian,P.

E.

Batson,S.

L.

Sass,J.

Silcox,Phys.

Rev.

Lett.

75(1995)4744.

[10]C.

T.

Liu,E.

H.

Lee,E.

P.

George,A.

J.

Duncan,Scr.

Metall.

Mater.

30(1994)387.

[11]G.

K.

Dey,A.

Arya,J.

A.

Sekhar,J.

Mater.

Res.

15(2000)63.

[12]D.

A.

Muller,S.

Subramanian,P.

E.

Batson,J.

Silcox,S.

L.

Sass,ActaMater.

44(1996)1637.

[13]H.

Riedel,FractureatHighTemperatures,SpringerVerlag,Berlin,1987.

[14]J.

Y.

Kim,J.

Yu,Appl.

Phys.

Lett.

92(2008)092109.

[15]S.

Q.

Liu,W.

Q.

Sun,ActaMeter.

Sin.

24(1988)376.

[16]G.

Duscher,M.

F.

Chisholm,U.

Alber,M.

Ru¨hle,Nat.

Mater.

3(2004)621.

[17]R.

Schweinfest,A.

T.

Paxton,M.

W.

Finnis,Nature432(2004)1008.

[18]U.

Alber,H.

Mue`llejans,M.

Rue`hle,ActaMater.

47(1999)4047.

[19]F.

Ren,J.

W.

Nah,K.

N.

Tu,B.

S.

Xiong,L.

H.

Xu,J.

H.

L.

Pang,Appl.

Phys.

Lett.

89(2006)141914.

[20]D.

T.

L.

VanAgterveld,G.

Palasantzas,J.

T.

M.

DeHosson,ActaMater.

48(2000)1995.

Figure4.

FracturesurfacesofSnBi/Cu,SnBi/Cu–18.

7AgandCu–2.

3Al/SnBijoints.

(a)SnBi/Cujointas-reowed;(b)agedat120°Cfor8.

25days—theleftinsetdisplaysamagniedmorphology,therightinsetdisplaysthecross-sectionmorphology;(c)as-reowedSnBi/Cu–18.

7Agjointandthejointagedfor11days;and(d)as-reowedSnBi/Cu–2.

3Aljointandthejointagedfor17days.

H.

F.

Zouetal.

/ScriptaMaterialia61(2009)308–311311

- turewww相关文档

- 靛奖www.yijia.com

- 公司www.yijia.com

- Addwww.yijia.com

- www.yijia.com开公司要多少钱才可以注册

- www.yijia.com汽车维修营业执照办理

- www.yijia.com注册一个公司 请代办注册公司 一般最快多久能拿到营业执照

华为云(69元)828促销活动 2G1M云服务器

华为云818上云活动活动截止到8月31日。1、秒杀限时区优惠仅限一单!云服务器秒杀价低至0.59折,每日9点开抢秒杀抢购活动仅限早上9点开始,有限量库存的。2G1M云服务器低至首年69元。2、新用户折扣区优惠仅限一单!购云服务器享3折起加购主机安全及数据库。企业和个人的优惠力度和方案是不同的。比如还有.CN域名首年8元。华为云服务器CPU资源正常没有扣量。3、抽奖活动在8.4-8.31日期间注册并...

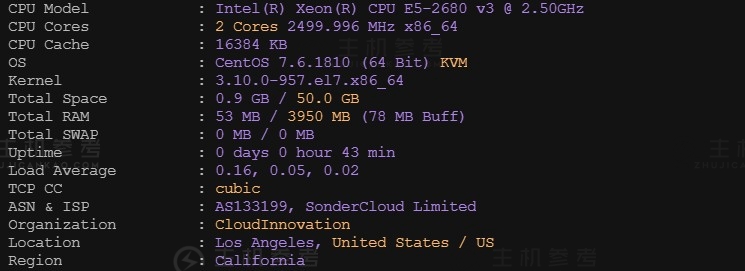

恒创科技SonderCloud,美国VPS综合性能测评报告,美国洛杉矶机房,CN2+BGP优质线路,2核4G内存10Mbps带宽,适用于稳定建站业务需求

最近主机参考拿到了一台恒创科技的美国VPS云服务器测试机器,那具体恒创科技美国云服务器性能到底怎么样呢?主机参考进行了一番VPS测评,大家可以参考一下,总体来说还是非常不错的,是值得购买的。非常适用于稳定建站业务需求。恒创科技服务器怎么样?恒创科技服务器好不好?henghost怎么样?henghost值不值得购买?SonderCloud服务器好不好?恒创科技henghost值不值得购买?恒创科技是...

spinservers($179/月),1Gbps不限流量服务器,双E5-2630Lv3/64GB/1.6T SSD/圣何塞机房

中秋节快到了,spinservers针对中国用户准备了几款圣何塞机房特别独立服务器,大家知道这家服务器都是高配,这次推出的机器除了配置高以外,默认1Gbps不限制流量,解除了常规机器10TB/月的流量限制,价格每月179美元起,机器自动化上架,一般30分钟内,有基本自助管理功能,带IPMI,支持安装Windows或者Linux操作系统。配置一 $179/月CPU:Dual Intel Xeon E...

www.yijia.com为你推荐

-

摩拜超15分钟加钱怎么领取摩拜单车免费卷openeuleropen与close的区别及用法安徽汽车网合肥汽车站网上售票同ip域名两个网站同一个IP怎么绑定两个域名haole018.com为什么www.haole008.com在我这里打不开啊,是不是haole008换新的地址了?51sese.comwww.51xuanh.com这是什么网站是骗人的吗?99nets.com99nets网游模拟娱乐社区怎么打不开了?????????谁能告诉我 ???、33tutu.comDnf绝望100鬼泣怎么过javlibrary.comsony home network library官方下载地址www.175qq.com最炫的qq分组