test7po.com

7po.com 时间:2021-03-21 阅读:()

JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665https://doi.

org/10.

1007/s13202-019-0652-7ORIGINALPAPER-PRODUCTIONENGINEERINGInfluenceoflaurylbetaineonaqueoussolutionstability,foamabilityandfoamstabilityAsadHassanSyed1·AhmadKamalIdris1·DzetiFarhahMohshim1·NurudeenYekeen2·MuhammadAliBuriro3Received:2November2018/Accepted:30March2019/Publishedonline:3April2019TheAuthor(s)2019AbstractIngasflooding,oneofthemajorproblemsinimplementingfoamasagasmobilitycontrolmethodisthestabilityoffoam.

Foamboosterwhenblendedwithsurfactantcouldimprovethefoamstability.

However,theinfluenceoffoamboosterontheconventionalfoamstabilityandfoamabilityatelevatedtemperatureandpresenceofinorganicelectrolytesisnotyetexplicitduetolimitedstudiesinthisarea.

Theobjectiveofthepresentworkwastoevaluatetheinfluenceofafoamboosteronaqueoussolutionstability,foamabilityandfoamstabilitywhenblendedwithsurfactantatdifferentratiosatanelevatedtemperatureinthepresenceofbrinecomposedofmonovalentanddivalentions.

ThreedifferentsurfactantsAOSC14–16(alpha-olefinsulfonate),SDS(sodiumdodecylsulfate)andalocallymanufacturedsurfactant'SurfX'werechosenasbasesurfactants.

Anamphotericsurfactantlaurylbetainewaschosenasafoamboosterinthisstudy.

Theaqueoussolutionstabil-itywasvisuallyevaluated,whereasthebulkfoamexperimentswereconductedinacommercialfoamanalyzerapparatus.

Itwasfoundthatnotallsolutionswerestablewhenlaurylbetainewasblended.

Laurylbetainedidnotimprovethefoamgenerationtime.

Thefoamstabilitywasimproved;however,notallsolutionswereabletogeneratestablefoam.

'SurfX'wasabletogeneratemorestablefoamascomparedtoAOSandwhenblendedwithlaurylbetaineitalsorequiredlessamountoflaurylbetainetogeneratestablefoam.

KeywordsDivalentions·Foamability·Foamstability·Laurylbetaine·SurfactantIntroductionFoamisadispersionofgasinaliquidphasesuchthattheliquidisincontinuousphasehavingsomeofthegastrappedinsidethethinliquidfilmsknownaslamellae(Hiraski1989).

Thesurfactantmoleculesarepresentatthegasliquidinterface,andtherebystabilizethefoamfilms(Katgert2008;Yekeenetal.

2017a).

Ingasflooding,thechallengeassoci-atedwithinjectedgasispoorvolumetricsweepefficiency,becauseoflowviscosityanddensityofgascomparedtooil(Memonetal.

2016).

Foamhashigherapparentviscosityandcancontrolthemobilityofthegasbysubstantiallyhin-derthegasflowinporousmedia,whichforcesgastosweepporesthatitwouldnothavereachedwithoutfoam(Fara-jzadehetal.

2012).

Inshortfoamdivertgastowardzoneshavinglowerpermeability,itlimitsviscousfingeringandalsoreducesoverridingofgasinhighpermeabilityzonesofreservoir(Yekeenetal.

2018;Chevallieretal.

2019).

Therearetwomainmethodsbywhichfoamcanbegener-atedinporousmedia,surfactantalternatinggas(SAG)and*AsadHassanSyedengr.

syedasadhassan@gmail.

comAhmadKamalIdrisahmadkamal.

idris@utp.

edu.

myDzetiFarhahMohshimdzetifarhah.

mohshim@utp.

edu.

myNurudeenYekeenpeteryekeen@yahoo.

com1DepartmentofPetroleumEngineering,FacultyofGeoscienceandPetroleumEngineering,UniversityTeknologiPETRONAS,32610SeriIskandar,Perak,Malaysia2InstituteofHydrocarbonRecovery,UniversitiTeknologiPETRONAS,32610BandarSeriIskandar,Perak,Malaysia3PetroleumEngineeringDepartment,KomarUniversityofScienceandTechnology,Sulaymaniyah,Iraq2660JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665co-injectionofsurfactantandgas(JensenandFriedmann1987;Farajzadehetal.

2012).

Asanenhancedoilrecovery(EOR)method,amajorcon-cernwiththeapplicationoffoamisthestabilityoffoam(Yekeenetal.

2018).

Theselectionandconcentrationofproperfoamingagentsareoneofthemainparametersthatdeterminesthesuccessoffoamflooding(Rafatietal.

2012).

Comparedtoanindividualcomponent,studieshaveshownthatwhenfoamboosterisusedasanadditivetheymayimprovethefoamproperties(VanDerBent2014;Cui,2014;Osei-Bonsuetal.

2015;SakaiandKaneko2004).

Betainesareknownfortheirfoamenhancingproperties(SakaiandKaneko2004;Farajzadehetal.

2012).

Previousstudieshaveshownthatzwitterionicbetainesurfactantshavetheabilitytoimprovestabilityofthefoamfilmsintheabsenceandpresenceofoil(Bashevaetal.

2000;Cui2014).

Gaoetal.

2017intheirresearchshownthattheadditionofbetaineimprovesthefoamstability.

ItwasobservedthatmorestablefoamwasgeneratedwhenlaurylbetainewasaddedtotheNI(Neodol67-7POsulfateandIOS15–18)4:1blend(Lietal.

2012).

Laurylbetaineisanamphotericsurfactantthatisthermallystablerelativetococamidopropyl-betaine(Cui2014).

Itwasalsoobservedinsomeotherstudiesthatblendinglaurylbetainedoesimprovethefoamproperties(Connetal.

2014;SinghandMohanty2016).

TheblendtestedbySinghandMohanty(2016)con-sistedof(1:1)AOSandLBwithbrinehavingsalinity1.

2wt%withoutthepresenceofdivalentions,.

whereasConnetal.

(2014)studywaslimitedto1:1ofmainsurfactant(AOS)andlaurylbetaineasfoamboosterwithatotalcon-centrationof1wt%,inthepresenceofNaClbrine.

Thepresenceofdivalentionscancausethesurfactanttoprecipitateintheformationbecauseoftheintoleranceofmanysurfactantstothedivalentions.

Soitisimportanttotestsurfactantsolutionsforfoamstudiesinthepresenceofdivalentions.

However,whenmixedwithdifferentsur-factants,theinfluenceoflaurylbetaineonaqueoussolutionstability,foamabilityandfoamstabilityinthepresenceofdivalentionsathightemperaturehasnotbeenextensivelyinvestigatedinpreviousstudies.

Thisexperimentalevaluationstudiedtheinfluenceoflaurylbetaineonaqueoussolutionstability,foamabilityandfoamstabilitywhenblendedwithsurfactantatdif-ferentratiosinthepresenceofbrinecontainingdiva-lentionsat60°C.

InthisworkAOSC14–16,SDSandalocallymanufacturedsurfactant'SurfX'chosenasbasesurfactantwassystematicallyblendedwithlaurylbetaine(foambooster)atdifferentratiosinabrinecontainingNaClandCaCl2.

Exceptthefoamstabilitytestwhichwasconductedatonly60°C,allothertestswereconductedat25°Cand60°C.

Theaqueoussolutionstabilitywasvisu-allyevaluated,whereasthefoamabilityandfoamstabilityexperimentswereconductedinacommercialFoamscanapparatus.

Inbulkfoamtests,half-life(foamstability)andfoamabilitywereinvestigated.

Inthisstudy,acomparativeunderstandingoftheinfluenceoflaurylbetaine(whichwehereaftercalledLB)onaqueoussolutionstability,foama-bility,foamstabilitywhenblendedwithbasesurfactantwasstudiedtogenerateastablefoamsolutionthatcanbefurthertestedinporousmedia.

MaterialsandmethodsMaterialsAOSC14-16(Alpha-olefinsulfonate)wasobtainedfromSTEPANChemicalCo.

'SurfX'alocallydevelopedsur-factant,SDS(sodiumdodecylsulfate)fromSigmaCo.

andFentacareBS12/LaurylBetaine(additive),receivedfromSolvayChemicalsCo.

Thebrinewaspreparedwithdeion-izedwaterandwiththeconcentrationof3.

0wt%ofNaClfromMerckCo.

,0.

20wt%CaCl2fromR&MChemicals.

Thetotalbrinesalinitywas3.

2wt%.

PureN2gaswasusedinthisstudyasthesparginggas.

Theinjectionratewas50ml/minforallthesolutions.

Allthesolutioncontainedtotalconcentrationof0.

5wt%activesurfactant.

Thecon-centrationusedinthisstudywaswellabovethecriticalmicelleconcentration.

TheCMCvalueofAOSat3.

0wt%NaClbrinewas0.

003wt%(Laskaris2015).

ThedetailsofthesurfactantsolutionstestedinthisstudyaregiveninTable1.

LabelA100,S100andX100denotestoAOS,SDSand'SurfX',respectively,withouttheLBblend,whereasA91,S91,X91shows9:1,A73,S73,X73shows7:3andA64,X64,S64shows6:4blendsofAOS,SDSand'SurfX'withLB,respectively.

Table1SurfactantsolutionsandLBblendusedintheexperimentsSampleno.

LabelBasesurfFoamboosterRatio(Surf/LB)1A100AOS––2A91AOSLB9:13A73AOSLB7:34A64AOSLB6:45X100SurfX––6X91SurfXLB9:17X73SurfXLB7:38X64SurfXLB6:49S100SDS––10S91SDSLB9:111S73SDSLB7:312S64SDSLB6:42661JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665ExperimentalprocedureThisresearchisdividedintotwomainphases.

Inthefirstphase,theaqueousstabilitytestingofthesurfactantsolutionwasconducted.

Inaqueousstabilitytesting,thereweretwotypesoftest.

Firstoneistheprecipitationtesting(inthistestthesolutionswerecheckedforanytypeofprecipitation)andsecondisthethermalstabilitytesting(inthistest,phasesep-arationwaschecked).

Firsttheindividualsurfactantsweretested.

Inthesecondpart,thefoambooster(LB)wasaddedatdifferentratiosasmentionedinTable1.

Thesurfactantsolutionswerestoredatdifferenttemperatures(25°Cand60°C)for2weeks,whichwerethanvisuallyinspected.

Asurfactantsolutionisconsideredstable,ifthesolutionishomogeneous,containsinglephaseandclear.

Ifthesur-factantsolutionthatisusedforinjectionisnotinsinglephaseandclearwillhavesignificantphasetrapping,forma-tionplugging,andlossofsurfactantsolutiontoadsorptionintheformationwilloccur.

AsshowninFig.

1ifthesolutionwasclearorslightlyblurry,itwasconsideredaqueouslysta-ble.

Ifasolutionwascloudyorifasolutionhasprecipitates,thenitwasconsideredunstableandwasnotusedforfurthertesting.

Inthesecondphase,thebulkfoamexperimentswerecar-riedoutusingFoamscanapparatus(Teclisinstruments).

Figure2showstheschematicdiagramofthefoamanalyzerapparatususedinthisresearch.

Bulkfoamtestwascon-ductedatambientand60°C.

First,a50mlofthesolutionsamplewasinjectedintotheglasstubeafterthatthepureN2(nitrogen)gasat50ml/minwasinjectedassparginggastocreatethefoam.

Thefoamabilityofthesolutionswastestedbygeneratingupto100mloffoam,andthen,thetimeforthefoamtoreachthe100mlfoamvolumewasrecorded.

Thebulkfoamstabilitywasmeasuredby(half-life)thetimeneededforthefoamtodecayintohalfofitsoriginalvolumeafterthespargingofthegaswasstopped.

ResultsanddiscussionAqueousandthermalsolutionstabilitytestingAqualifiedsurfactantformulationforfoamEORshouldbesolubleandstablefrominjectiontoreservoirconditions(Cui2014).

ItisimportanttotestaqueousandthermalsolutionFig.

1Resultsofsurfactantaqueoussolutionstability,aaclearstablesolution,baslightlyblurrysolution,cacloudy/precipitatedsolutionFig.

2SchematicdiagramofFoamscanapparatus(Jonesetal.

2016)2662JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665stabilitybecauseifasolutionisnotstable(singlephase)andprecipitatesinsideformationthenitwillblocktheporesanddamagetheformation.

ResultsoftheaqueoussolutionstabilitytestscanbeseeninTable2.

Allthebasesurfactantsolutionsinthepresenceofbrineweretestedattempera-tures25°Cand60°C.

Testedbasesurfactantsolutionswerefoundclear,andnophaseseparationandprecipitationwereobserved.

ThebasesurfactantwasthenfurtherusedtoblendwiththeLBforfurthertesting.

Inthesecondphase,thefoambooster(LB)wasblendedwiththebasesurfactantatratios9:1,7:3and6:4asmentionedinTable1.

AfterblendingtheLBandbasesurfactants,aqueousandthermalstabilityweretested.

ThesolutionsA91,A73,X91,X73werefoundstable,andnophaseseparationorprecipitationwasobservedatbothtemperatures25°Cand60°C.

TheA73showedalittleblurrysolutionat25°Ctemperature;however,whenitwastestedat60°C,itwasfoundclear.

ThesolutionA64,X64,S73andS64werecloudyandhasprecipitationat25°C.

Whenthesesolutionswerefurthertestedat60°C.

Precipita-tionsandcloudysolutionswerestillobserved;however,thesolutionS73at60°Cwashazy,buttheprecipitationwasstillpresentinthesolution.

ItwasobservedinthisstudythatastheratioofLBincreasedinthesurfactantsolutions,ithadanegativeinfluenceonthestabilityofthesurfactantsolution.

NotallthesurfactantsolutionswerefoundstableastheratioofLBincreasedinthesurfactantsolution.

Complexinteractionamongthedivalentionsandsurfactantmoleculescouldhavethepossibilityofreductioninmicelleformationthatwouldleadtopresenceoflargenumberoffreemono-merswhichinturnbindwithdivalentions.

Thisbindingofdivalentionscouldbethepossiblereasonforprecipitation.

TheA64,X64,S100,S91,S73andS64surfactantsolu-tionswasnotfurtherusedfortestinginthisstudy.

BulkfoamtestFoamabilityTheeaseoffoamgenerationisknownasfoamability.

Itisadynamicpropertyoffoamgeneratingpowerofaliquidandthefactorsthathelptoattainimmediatestabilizationofthefoam(Wilson1996;SakaiandKaneko2004).

TheinfluenceofLBonfoamabilityisshowninFig.

3aat25°CandFig.

3bat60°CwhenblendedwithAOSand'SurfX'surfactant,respectively.

AsshowninFig.

3a,b,thefoamabilitytimeoftheindividualsurfactantsolutionsascomparedtothemixedsurfactantsolutionswasbetter.

AsshowninFig.

3a,whenAOSwasblendedwithLBat9:1,thefoamabilitytimeat25°Cwasincreasedby39.

08%.

At7:3,thetimewasincreasedby27.

58%.

When'SurfX'wasblendedwithLBat9:1,thetimewas27.

47%morethanindividual'SurfX'.

At7:3,thefoamabilitytimewasincreasedby30.

76%ascomparedtothetimeforbase'SurfX'surfactant.

Figure3brepresentsthefoamabilityofsurfactantsolu-tionsat60°C.

WhenAOSwasblendedwithLBat9:1,thefoamabilitytimewasincreasedby26.

47%.

At7:3,thetimewasincreasedby20.

58%.

When'SurfX'wasblendedwithLBat9:1,thetimewasonly5.

79%more.

At7:3,theTable2Aqueoussolutionstabilityresultsofthesurfactantsolutionstestedat25°Cand60°CSampleno.

Label25°C60°CRemarksRemarks1A100ClearClear2A91ClearClear3A73Blurry/hazyClear4A64Cloudy/precipitationCloudy/precipitation5X100ClearClear6X91ClearClear7X73ClearClear8X64Cloudy/precipitationCloudy/precipitation9S100ClearClear10S91ClearClear11S73Cloudy/precipitationBlurry/precipitation12S64Cloudy/precipitationCloudy/precipitationFig.

3Timeneededtogener-ate100mlfoamfordifferentsurfactantsolutionswithandwithoutfoambooster(LB)ata25°Candb60°C(a)020406080100120140A100A91A73X100X91X73Time(Seconds)FoamabilityatT=25°C(b)020406080100120140A100A91A73X100X91X73Time(Seconds)FoamabilityatT=60°C2663JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665foamabilitytimewas27.

53%moreascomparedtothetimefor'SurfX'withouttheblendofLB.

Temperaturehadapositiveeffectonthefoamabilityofallthesurfactantsolutionstestedinthisstudy.

Thefoamabil-itytimeofsurfactantsolutionsatelevatedtemperaturewasmuchbetterascomparedtothefoamabilitytimeatlowertemperature.

Theimprovementinfoamabilityat60°Ccom-paredto25°Ccouldbeattributedtotheincreaseintheinternalkineticenergyofthegasduetoincreaseintem-peratureandthedecreaseinliquidviscosityofthesurfactantsolution.

Atbothtemperatures25°Cand60°C,thesur-factantsolutionsA100andX100withouttheblendofLBhadbetterfoamabilitytime.

Thefoamabilityperformanceofthesurfactantsolutionstestedinthisstudyat25°Carerankedintheorderof:A100>X100>A73>X91>X73>A91,whereasat60°Ctemperaturetheorderisasfol-lows:A100>X100>X91>A73>A91>X73.

Inthiswork,LBwasnotabletohaveapositiveimpactonthefoamabilityofsurfactantsolutionsused.

LBhasmorenegativeimpactonfoamabilitywhenblendedwithAOSascomparedtothe'SurfX'surfactant.

(SakaiandKaneko2004;VanDerBent2014)intheirstudyalsofoundthesimilartrendthattheadditionofamphotericsurfactantdidnotimprovethefoamability.

Figure4showsA100foamgeneratedinsideaglasstube.

FoamstabilityFoamstabilitycanbedefinedasthetimeafoamfilmexistswithoutrupturing(SakaiandKaneko2004).

Itisgenerallyindicatedbyfoamhalf-life(timeneededforfoamtodecayhalfofitsoriginalfoam)(Yekeenetal.

2017b)Fig.

5showsthehalf-lifeofthebulkfoamexperiments,bothwithandwithouttheblendofLBat60°C,withlongerhalf-lifeindi-catingamorestablefoam.

AOSandLBblendof9:1gener-ated149.

68%morestablefoamascomparedtoindividualAOSsurfactantsolutions.

WhenAOSwasblendedwithLBatratioof7:3,itincreasedhalf-lifeby254.

91%.

When'SurfX'wasblendedwithLBat9:1,itshowedanimprovementinstabilitybyjust8.

92%;however,whentheblendratiowasincreasedandthe'SurfX'andLBwasblendedat7:3,therewasadecreaseinstabilityofabout39.

89%.

Incomparisonofindividualsurfactantsolution,X100hashigherfoamstabilityascomparedtoA100surfactantsolutiongeneratedfoam.

Thehalf-lifeofthesurfactantsolu-tionswasimprovedwhenLBwasblendedwiththeAOSand'SurfX'surfactants.

TheinfluenceonthestabilitywasmoreprofoundwithAOSsurfactantascomparedtothe'SurfX'surfactant.

AmongallthesurfactantblendedwiththeLB,'SurfX'neededlessamountofLBascomparedtotheAOS.

IncreasingtheratioofLBwith'SurfX'wasnotabletogreatlyimprovefoamstabilityatalltheratiostested.

TheA73surfactantsolutiongeneratedthemoststablefoamamongFig.

4A100foaminsideglasstubeFig.

5Foamdecayprofileofdifferentsurfactantsolutionswithandwithoutthefoambooster(LB)at60°C2664JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665allthesurfactantsolutiontested.

BasedonFig.

5,thefoamstabilityaccordingtohalf-lifeisrankedasthefollowingA73>X91>X100>A91>X73>A100.

Theincreaseinfoamstabilitywiththeblendofanamphotericsurfactanthasalsobeenreportedbyotherresearchers(Osei-Bonsuetal.

2015;Memonetal.

2016).

Ascomparedtoindividualcom-ponentsystems,theblendofdifferenttypeofsurfactantssynergisticallyexhibitbetterfoamingproperties(Bianetal.

2012;Memonetal.

2016).

ThisresultoftheincreaseinthefoamstabilitybyLBcanbeduetotheMarangonieffect,whichiscausedbyelectrostaticattractionbetweenanionicsurfactantandthecationicnitrogen(Domingo1996;SakaiandKaneko2004).

Gaoetal.

(2017)showedintheirstudyusingthesimulationforfoamstabilitythatthepresenceofamphotericsurfactantrelaxestherepulsionbetweentheheadgroupsofanionicsur-factants.

ThismechanismimprovedthefoamstabilityandcouldalsoberesponsiblefortheimprovedfoamstabilityinthepresenceofLBasobservedinthisresearch.

Moreover,itisanticipatedthatadditionofLBtothesolutioncouldincreasetheliquidviscosity,consequentlydecreasingtheliquiddrainagefromthefoamplateauborderswhichcauseshighresistancetofilmthinning,thusinfluencesthestabilityoffoam(Osei-Bonsuetal.

2015).

ConclusionInthiswork,whenblendedwithdifferentsolutions,theinfluenceoflaurylbetaineontheaqueoussolutionstabil-ity,foamabilityandbulkfoamstabilityinthepresenceofdivalentionsandatanelevatedtemperaturewerestudied.

Parameterssuchastheaqueoussolutionstability(phaseseparationandprecipitation),foamabilityandfoamsta-bilityweresystematicallyinvestigated.

Itwasfoundthatblendinglaurylbetainewithsurfactantaffectsthesolutionstability;notallthesolutionwasfoundstableastheratioofLBincreasedinthesurfactantsolutioninthepresenceofdivalentions.

Therewasanegativeimpactonfoamabil-itywhenlaurylbetainewasblendedwiththesurfactant.

A100andX100surfactantsolutionshadthebestfoamabilitytimeatboththetestedtemperatures.

Thefoamstabilityofthesolutionswasimproved;however,notallsolutionswereabletogeneratestablefoam.

'SurfX'individuallywasabletogeneratemorestablefoamascomparedtoAOSandwhenblendedwithlaurylbetaine.

Italsorequiredlessamountoflaurylbetainetogeneratemorestablefoam.

TheA73surfactantsolutiongeneratedthemoststablefoamfollowedbyX91surfactantsolution.

Thepresenceoflaurylbetaine(10%)in'SurfX'increasedthefoamstabilitybyapproxi-mately9%,whereasthepresenceoflaurylbetaine(30%)inAOSsurfactantsolutionincreasedthefoamstabilitybyapproximately255%.

Thesurfactantsolutionusedinthisstudythatgeneratedstablefoamwillbefurthertestedinporousmedia.

AcknowledgementAuthorswouldliketothankStepanCo.

andSolvayChemicalsCo.

forprovidingchemicalsusedinthisresearch.

AuthorswouldalsoliketothankInstituteofHydrocarbonRecovery,CentreofResearchofEnhancedOilRecovery(COREOR),Univer-sitiTeknologiPETRONASandtotheMinistryofHigherEducation(MOHE),(0153AB-L59)forsupportingthisresearchthroughfunda-mentalresearchGrantscheme.

OpenAccessThisarticleisdistributedunderthetermsoftheCrea-tiveCommonsAttribution4.

0InternationalLicense(http://creativecommons.

org/licenses/by/4.

0/),whichpermitsunrestricteduse,distribu-tion,andreproductioninanymedium,providedyougiveappropriatecredittotheoriginalauthor(s)andthesource,providealinktotheCreativeCommonslicense,andindicateifchangesweremade.

ReferencesBashevaES,GanchevD,DenkovNDetal(2000)Roleofbetaineasfoamboosterinthepresenceofsiliconeoildrops.

Langmuir16:1000–1013.

https://doi.

org/10.

1021/la990777+BianY,PennyGS,SheppardNCetal(2012)Surfactantformulationevaluationforcarbondioxidefoamfloodinginheterogeneoussandstonereservoir.

SPEImprovOilRecoverSymp.

https://doi.

org/10.

2118/154018-msChevallierE,DemazyN,CuencaA,ChabertM(2019)Correlationbetweenfoamflowstructureinporousmediaandsurfactantformulationproperties.

TranspPorousMedia.

https://doi.

org/10.

1007/s11242-018-01226-2ConnCA,MaK,HirasakiGJ,BiswalSL(2014)Visualizingoildis-placementwithfoaminamicrofluidicdevicewithpermeabilitycontrast.

LabChip14:3968–3977.

https://doi.

org/10.

1039/c4lc00620hCuiL(2014)Applicationoffoamformobilitycontrolinenhancedoilrecovery(EOR)process.

PhDdissertation,RiceUniversityDomingoX(1996)Betaines.

In:LomaxEG(ed)Amphotericsur-factants,2ndedn.

MarcelDekker,NewYork,p75FarajzadehR,AndrianovA,KrastevRetal(2012)Foam-oilinterac-tioninporousmedia:implicationsforfoamassistedenhancedoilrecovery.

AdvColloidInterfaceSci183–184:1–13.

https://doi.

org/10.

1016/j.

cis.

2012.

07.

002GaoF,LiuG,YuanS(2017)Theeffectofbetaineonthefoamstabil-ity:molecularsimulation.

ApplSurfSci407:156–161.

https://doi.

org/10.

1016/j.

apsusc.

2017.

02.

087HiraskiGJ(1989)Thesteam-foamprocess.

SocPetEng.

https://doi.

org/10.

2118/19505-paJensenJA,FriedmannF(1987)Physicalandchemicaleffectsofanoilphaseonthepropagationoffoaminporousmedia.

SPECalifor-niaRegionalMeeting.

SocietyofPetroleumEngineers,Ventura,California.

https://doi.

org/10.

2118/16375-MSJonesSA,vanderBentV,FarajzadehR,RossenWR,Vincent-BonnieuS(2016)SurfactantscreeningforfoamEOR:Correlationbetweenbulkandcore-floodexperiments.

ColloidsSurfPhysicochemEngAsp500:166–176.

https://doi.

org/10.

1016/j.

colsurfa.

2016.

03.

072KatgertG(2008)Flowoffoams.

DoctoralDissertation,UniversiteitLeidenLaskarisG(2015)Effectofsurfactantconcentration,watertreatmentchemicals,fattyacidsandalcoholsonfoambehaviorinporous2665JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665mediaandinbulk.

Mastersdissertation,TUDelftUniversity,NetherlandLiRF,HirasakiG,MillerCA,MasalmehSK(2012)Wettabil-ityalterationandfoammobilitycontrolinalayered,2dhet-erogeneoussandpack.

SPEIntSympOilfChem.

https://doi.

org/10.

2118/141462-paMemonMK,ShukerMT,ElraiesKA(2016)Studyofblendedsur-factantstogeneratestablefoaminpresenceofcrudeoilforgasmobilitycontrol.

JPetExplorProdTechnol7:77–85.

https://doi.

org/10.

1007/s13202-016-0243-9Osei-BonsuK,ShokriN,GrassiaP(2015)Foamstabilityinthepres-enceandabsenceofhydrocarbons:frombubble-tobulk-scale.

ColloidsSurfAPhysicochemEngAsp481:514–526.

https://doi.

org/10.

1016/j.

colsurfa.

2015.

06.

023RafatiR,HamidiH,IdrisAK,MananMA(2012)Applicationofsus-tainablefoamingagentstocontrolthemobilityofcarbondioxideinenhancedoilrecovery.

EgyptJPet21:155–163.

https://doi.

org/10.

1016/j.

ejpe.

2012.

11.

010SakaiT,KanekoY(2004)Theeffectofsomefoamboostersonthefoamabilityandfoamstabilityofanionicsystems.

JSurfactantsDeterg7:291–295.

https://doi.

org/10.

1007/s11743-004-0314-xSinghR,MohantyKK(2016)Foamswithwettability-alteringcapabili-tiesforoil-wetcarbonates:asynergisticapproach.

SPEJ21:1126–1139.

https://doi.

org/10.

2118/175027-PAVanDerBentVJ(2014)Comparativestudyoffoamstabilityinbulkandporousmedia.

Mastersthesis,DelftUniversityofTechnologyWilsonAJ(1996)Experimentaltechniquesforthecharacterizationoffoams.

In:Prud'hommeRK,KhanSA(eds)Foams:theory,measurements,andapplication.

MarchelDekker,Inc,NewYork,pp243–272YekeenN,IdrisAK,MananMA,SaminAM(2017a)Experimentalstudyoftheinfluenceofsilicananoparticlesonthebulkstabil-ityofSDS-foaminthepresenceofoil.

JDispersSciTechnol38:416–424.

https://doi.

org/10.

1080/01932691.

2016.

1172969YekeenN,MananMA,IdrisAK,SaminAM(2017b)InfluenceofsurfactantandelectrolyteconcentrationsonsurfactantAdsorptionandfoamingcharacteristics.

JPetSciEng149:612–622.

https://doi.

org/10.

1016/j.

petrol.

2016.

11.

018YekeenN,MananMA,IdrisAKetal(2018)Acomprehensivereviewofexperimentalstudiesofnanoparticles-stabilizedfoamforenhancedoilrecovery.

JPetSciEng164:43–74.

https://doi.

org/10.

1016/j.

petrol.

2018.

01.

035Publisher'sNoteSpringerNatureremainsneutralwithregardtojurisdictionalclaimsinpublishedmapsandinstitutionalaffiliations.

org/10.

1007/s13202-019-0652-7ORIGINALPAPER-PRODUCTIONENGINEERINGInfluenceoflaurylbetaineonaqueoussolutionstability,foamabilityandfoamstabilityAsadHassanSyed1·AhmadKamalIdris1·DzetiFarhahMohshim1·NurudeenYekeen2·MuhammadAliBuriro3Received:2November2018/Accepted:30March2019/Publishedonline:3April2019TheAuthor(s)2019AbstractIngasflooding,oneofthemajorproblemsinimplementingfoamasagasmobilitycontrolmethodisthestabilityoffoam.

Foamboosterwhenblendedwithsurfactantcouldimprovethefoamstability.

However,theinfluenceoffoamboosterontheconventionalfoamstabilityandfoamabilityatelevatedtemperatureandpresenceofinorganicelectrolytesisnotyetexplicitduetolimitedstudiesinthisarea.

Theobjectiveofthepresentworkwastoevaluatetheinfluenceofafoamboosteronaqueoussolutionstability,foamabilityandfoamstabilitywhenblendedwithsurfactantatdifferentratiosatanelevatedtemperatureinthepresenceofbrinecomposedofmonovalentanddivalentions.

ThreedifferentsurfactantsAOSC14–16(alpha-olefinsulfonate),SDS(sodiumdodecylsulfate)andalocallymanufacturedsurfactant'SurfX'werechosenasbasesurfactants.

Anamphotericsurfactantlaurylbetainewaschosenasafoamboosterinthisstudy.

Theaqueoussolutionstabil-itywasvisuallyevaluated,whereasthebulkfoamexperimentswereconductedinacommercialfoamanalyzerapparatus.

Itwasfoundthatnotallsolutionswerestablewhenlaurylbetainewasblended.

Laurylbetainedidnotimprovethefoamgenerationtime.

Thefoamstabilitywasimproved;however,notallsolutionswereabletogeneratestablefoam.

'SurfX'wasabletogeneratemorestablefoamascomparedtoAOSandwhenblendedwithlaurylbetaineitalsorequiredlessamountoflaurylbetainetogeneratestablefoam.

KeywordsDivalentions·Foamability·Foamstability·Laurylbetaine·SurfactantIntroductionFoamisadispersionofgasinaliquidphasesuchthattheliquidisincontinuousphasehavingsomeofthegastrappedinsidethethinliquidfilmsknownaslamellae(Hiraski1989).

Thesurfactantmoleculesarepresentatthegasliquidinterface,andtherebystabilizethefoamfilms(Katgert2008;Yekeenetal.

2017a).

Ingasflooding,thechallengeassoci-atedwithinjectedgasispoorvolumetricsweepefficiency,becauseoflowviscosityanddensityofgascomparedtooil(Memonetal.

2016).

Foamhashigherapparentviscosityandcancontrolthemobilityofthegasbysubstantiallyhin-derthegasflowinporousmedia,whichforcesgastosweepporesthatitwouldnothavereachedwithoutfoam(Fara-jzadehetal.

2012).

Inshortfoamdivertgastowardzoneshavinglowerpermeability,itlimitsviscousfingeringandalsoreducesoverridingofgasinhighpermeabilityzonesofreservoir(Yekeenetal.

2018;Chevallieretal.

2019).

Therearetwomainmethodsbywhichfoamcanbegener-atedinporousmedia,surfactantalternatinggas(SAG)and*AsadHassanSyedengr.

syedasadhassan@gmail.

comAhmadKamalIdrisahmadkamal.

idris@utp.

edu.

myDzetiFarhahMohshimdzetifarhah.

mohshim@utp.

edu.

myNurudeenYekeenpeteryekeen@yahoo.

com1DepartmentofPetroleumEngineering,FacultyofGeoscienceandPetroleumEngineering,UniversityTeknologiPETRONAS,32610SeriIskandar,Perak,Malaysia2InstituteofHydrocarbonRecovery,UniversitiTeknologiPETRONAS,32610BandarSeriIskandar,Perak,Malaysia3PetroleumEngineeringDepartment,KomarUniversityofScienceandTechnology,Sulaymaniyah,Iraq2660JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665co-injectionofsurfactantandgas(JensenandFriedmann1987;Farajzadehetal.

2012).

Asanenhancedoilrecovery(EOR)method,amajorcon-cernwiththeapplicationoffoamisthestabilityoffoam(Yekeenetal.

2018).

Theselectionandconcentrationofproperfoamingagentsareoneofthemainparametersthatdeterminesthesuccessoffoamflooding(Rafatietal.

2012).

Comparedtoanindividualcomponent,studieshaveshownthatwhenfoamboosterisusedasanadditivetheymayimprovethefoamproperties(VanDerBent2014;Cui,2014;Osei-Bonsuetal.

2015;SakaiandKaneko2004).

Betainesareknownfortheirfoamenhancingproperties(SakaiandKaneko2004;Farajzadehetal.

2012).

Previousstudieshaveshownthatzwitterionicbetainesurfactantshavetheabilitytoimprovestabilityofthefoamfilmsintheabsenceandpresenceofoil(Bashevaetal.

2000;Cui2014).

Gaoetal.

2017intheirresearchshownthattheadditionofbetaineimprovesthefoamstability.

ItwasobservedthatmorestablefoamwasgeneratedwhenlaurylbetainewasaddedtotheNI(Neodol67-7POsulfateandIOS15–18)4:1blend(Lietal.

2012).

Laurylbetaineisanamphotericsurfactantthatisthermallystablerelativetococamidopropyl-betaine(Cui2014).

Itwasalsoobservedinsomeotherstudiesthatblendinglaurylbetainedoesimprovethefoamproperties(Connetal.

2014;SinghandMohanty2016).

TheblendtestedbySinghandMohanty(2016)con-sistedof(1:1)AOSandLBwithbrinehavingsalinity1.

2wt%withoutthepresenceofdivalentions,.

whereasConnetal.

(2014)studywaslimitedto1:1ofmainsurfactant(AOS)andlaurylbetaineasfoamboosterwithatotalcon-centrationof1wt%,inthepresenceofNaClbrine.

Thepresenceofdivalentionscancausethesurfactanttoprecipitateintheformationbecauseoftheintoleranceofmanysurfactantstothedivalentions.

Soitisimportanttotestsurfactantsolutionsforfoamstudiesinthepresenceofdivalentions.

However,whenmixedwithdifferentsur-factants,theinfluenceoflaurylbetaineonaqueoussolutionstability,foamabilityandfoamstabilityinthepresenceofdivalentionsathightemperaturehasnotbeenextensivelyinvestigatedinpreviousstudies.

Thisexperimentalevaluationstudiedtheinfluenceoflaurylbetaineonaqueoussolutionstability,foamabilityandfoamstabilitywhenblendedwithsurfactantatdif-ferentratiosinthepresenceofbrinecontainingdiva-lentionsat60°C.

InthisworkAOSC14–16,SDSandalocallymanufacturedsurfactant'SurfX'chosenasbasesurfactantwassystematicallyblendedwithlaurylbetaine(foambooster)atdifferentratiosinabrinecontainingNaClandCaCl2.

Exceptthefoamstabilitytestwhichwasconductedatonly60°C,allothertestswereconductedat25°Cand60°C.

Theaqueoussolutionstabilitywasvisu-allyevaluated,whereasthefoamabilityandfoamstabilityexperimentswereconductedinacommercialFoamscanapparatus.

Inbulkfoamtests,half-life(foamstability)andfoamabilitywereinvestigated.

Inthisstudy,acomparativeunderstandingoftheinfluenceoflaurylbetaine(whichwehereaftercalledLB)onaqueoussolutionstability,foama-bility,foamstabilitywhenblendedwithbasesurfactantwasstudiedtogenerateastablefoamsolutionthatcanbefurthertestedinporousmedia.

MaterialsandmethodsMaterialsAOSC14-16(Alpha-olefinsulfonate)wasobtainedfromSTEPANChemicalCo.

'SurfX'alocallydevelopedsur-factant,SDS(sodiumdodecylsulfate)fromSigmaCo.

andFentacareBS12/LaurylBetaine(additive),receivedfromSolvayChemicalsCo.

Thebrinewaspreparedwithdeion-izedwaterandwiththeconcentrationof3.

0wt%ofNaClfromMerckCo.

,0.

20wt%CaCl2fromR&MChemicals.

Thetotalbrinesalinitywas3.

2wt%.

PureN2gaswasusedinthisstudyasthesparginggas.

Theinjectionratewas50ml/minforallthesolutions.

Allthesolutioncontainedtotalconcentrationof0.

5wt%activesurfactant.

Thecon-centrationusedinthisstudywaswellabovethecriticalmicelleconcentration.

TheCMCvalueofAOSat3.

0wt%NaClbrinewas0.

003wt%(Laskaris2015).

ThedetailsofthesurfactantsolutionstestedinthisstudyaregiveninTable1.

LabelA100,S100andX100denotestoAOS,SDSand'SurfX',respectively,withouttheLBblend,whereasA91,S91,X91shows9:1,A73,S73,X73shows7:3andA64,X64,S64shows6:4blendsofAOS,SDSand'SurfX'withLB,respectively.

Table1SurfactantsolutionsandLBblendusedintheexperimentsSampleno.

LabelBasesurfFoamboosterRatio(Surf/LB)1A100AOS––2A91AOSLB9:13A73AOSLB7:34A64AOSLB6:45X100SurfX––6X91SurfXLB9:17X73SurfXLB7:38X64SurfXLB6:49S100SDS––10S91SDSLB9:111S73SDSLB7:312S64SDSLB6:42661JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665ExperimentalprocedureThisresearchisdividedintotwomainphases.

Inthefirstphase,theaqueousstabilitytestingofthesurfactantsolutionwasconducted.

Inaqueousstabilitytesting,thereweretwotypesoftest.

Firstoneistheprecipitationtesting(inthistestthesolutionswerecheckedforanytypeofprecipitation)andsecondisthethermalstabilitytesting(inthistest,phasesep-arationwaschecked).

Firsttheindividualsurfactantsweretested.

Inthesecondpart,thefoambooster(LB)wasaddedatdifferentratiosasmentionedinTable1.

Thesurfactantsolutionswerestoredatdifferenttemperatures(25°Cand60°C)for2weeks,whichwerethanvisuallyinspected.

Asurfactantsolutionisconsideredstable,ifthesolutionishomogeneous,containsinglephaseandclear.

Ifthesur-factantsolutionthatisusedforinjectionisnotinsinglephaseandclearwillhavesignificantphasetrapping,forma-tionplugging,andlossofsurfactantsolutiontoadsorptionintheformationwilloccur.

AsshowninFig.

1ifthesolutionwasclearorslightlyblurry,itwasconsideredaqueouslysta-ble.

Ifasolutionwascloudyorifasolutionhasprecipitates,thenitwasconsideredunstableandwasnotusedforfurthertesting.

Inthesecondphase,thebulkfoamexperimentswerecar-riedoutusingFoamscanapparatus(Teclisinstruments).

Figure2showstheschematicdiagramofthefoamanalyzerapparatususedinthisresearch.

Bulkfoamtestwascon-ductedatambientand60°C.

First,a50mlofthesolutionsamplewasinjectedintotheglasstubeafterthatthepureN2(nitrogen)gasat50ml/minwasinjectedassparginggastocreatethefoam.

Thefoamabilityofthesolutionswastestedbygeneratingupto100mloffoam,andthen,thetimeforthefoamtoreachthe100mlfoamvolumewasrecorded.

Thebulkfoamstabilitywasmeasuredby(half-life)thetimeneededforthefoamtodecayintohalfofitsoriginalvolumeafterthespargingofthegaswasstopped.

ResultsanddiscussionAqueousandthermalsolutionstabilitytestingAqualifiedsurfactantformulationforfoamEORshouldbesolubleandstablefrominjectiontoreservoirconditions(Cui2014).

ItisimportanttotestaqueousandthermalsolutionFig.

1Resultsofsurfactantaqueoussolutionstability,aaclearstablesolution,baslightlyblurrysolution,cacloudy/precipitatedsolutionFig.

2SchematicdiagramofFoamscanapparatus(Jonesetal.

2016)2662JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665stabilitybecauseifasolutionisnotstable(singlephase)andprecipitatesinsideformationthenitwillblocktheporesanddamagetheformation.

ResultsoftheaqueoussolutionstabilitytestscanbeseeninTable2.

Allthebasesurfactantsolutionsinthepresenceofbrineweretestedattempera-tures25°Cand60°C.

Testedbasesurfactantsolutionswerefoundclear,andnophaseseparationandprecipitationwereobserved.

ThebasesurfactantwasthenfurtherusedtoblendwiththeLBforfurthertesting.

Inthesecondphase,thefoambooster(LB)wasblendedwiththebasesurfactantatratios9:1,7:3and6:4asmentionedinTable1.

AfterblendingtheLBandbasesurfactants,aqueousandthermalstabilityweretested.

ThesolutionsA91,A73,X91,X73werefoundstable,andnophaseseparationorprecipitationwasobservedatbothtemperatures25°Cand60°C.

TheA73showedalittleblurrysolutionat25°Ctemperature;however,whenitwastestedat60°C,itwasfoundclear.

ThesolutionA64,X64,S73andS64werecloudyandhasprecipitationat25°C.

Whenthesesolutionswerefurthertestedat60°C.

Precipita-tionsandcloudysolutionswerestillobserved;however,thesolutionS73at60°Cwashazy,buttheprecipitationwasstillpresentinthesolution.

ItwasobservedinthisstudythatastheratioofLBincreasedinthesurfactantsolutions,ithadanegativeinfluenceonthestabilityofthesurfactantsolution.

NotallthesurfactantsolutionswerefoundstableastheratioofLBincreasedinthesurfactantsolution.

Complexinteractionamongthedivalentionsandsurfactantmoleculescouldhavethepossibilityofreductioninmicelleformationthatwouldleadtopresenceoflargenumberoffreemono-merswhichinturnbindwithdivalentions.

Thisbindingofdivalentionscouldbethepossiblereasonforprecipitation.

TheA64,X64,S100,S91,S73andS64surfactantsolu-tionswasnotfurtherusedfortestinginthisstudy.

BulkfoamtestFoamabilityTheeaseoffoamgenerationisknownasfoamability.

Itisadynamicpropertyoffoamgeneratingpowerofaliquidandthefactorsthathelptoattainimmediatestabilizationofthefoam(Wilson1996;SakaiandKaneko2004).

TheinfluenceofLBonfoamabilityisshowninFig.

3aat25°CandFig.

3bat60°CwhenblendedwithAOSand'SurfX'surfactant,respectively.

AsshowninFig.

3a,b,thefoamabilitytimeoftheindividualsurfactantsolutionsascomparedtothemixedsurfactantsolutionswasbetter.

AsshowninFig.

3a,whenAOSwasblendedwithLBat9:1,thefoamabilitytimeat25°Cwasincreasedby39.

08%.

At7:3,thetimewasincreasedby27.

58%.

When'SurfX'wasblendedwithLBat9:1,thetimewas27.

47%morethanindividual'SurfX'.

At7:3,thefoamabilitytimewasincreasedby30.

76%ascomparedtothetimeforbase'SurfX'surfactant.

Figure3brepresentsthefoamabilityofsurfactantsolu-tionsat60°C.

WhenAOSwasblendedwithLBat9:1,thefoamabilitytimewasincreasedby26.

47%.

At7:3,thetimewasincreasedby20.

58%.

When'SurfX'wasblendedwithLBat9:1,thetimewasonly5.

79%more.

At7:3,theTable2Aqueoussolutionstabilityresultsofthesurfactantsolutionstestedat25°Cand60°CSampleno.

Label25°C60°CRemarksRemarks1A100ClearClear2A91ClearClear3A73Blurry/hazyClear4A64Cloudy/precipitationCloudy/precipitation5X100ClearClear6X91ClearClear7X73ClearClear8X64Cloudy/precipitationCloudy/precipitation9S100ClearClear10S91ClearClear11S73Cloudy/precipitationBlurry/precipitation12S64Cloudy/precipitationCloudy/precipitationFig.

3Timeneededtogener-ate100mlfoamfordifferentsurfactantsolutionswithandwithoutfoambooster(LB)ata25°Candb60°C(a)020406080100120140A100A91A73X100X91X73Time(Seconds)FoamabilityatT=25°C(b)020406080100120140A100A91A73X100X91X73Time(Seconds)FoamabilityatT=60°C2663JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665foamabilitytimewas27.

53%moreascomparedtothetimefor'SurfX'withouttheblendofLB.

Temperaturehadapositiveeffectonthefoamabilityofallthesurfactantsolutionstestedinthisstudy.

Thefoamabil-itytimeofsurfactantsolutionsatelevatedtemperaturewasmuchbetterascomparedtothefoamabilitytimeatlowertemperature.

Theimprovementinfoamabilityat60°Ccom-paredto25°Ccouldbeattributedtotheincreaseintheinternalkineticenergyofthegasduetoincreaseintem-peratureandthedecreaseinliquidviscosityofthesurfactantsolution.

Atbothtemperatures25°Cand60°C,thesur-factantsolutionsA100andX100withouttheblendofLBhadbetterfoamabilitytime.

Thefoamabilityperformanceofthesurfactantsolutionstestedinthisstudyat25°Carerankedintheorderof:A100>X100>A73>X91>X73>A91,whereasat60°Ctemperaturetheorderisasfol-lows:A100>X100>X91>A73>A91>X73.

Inthiswork,LBwasnotabletohaveapositiveimpactonthefoamabilityofsurfactantsolutionsused.

LBhasmorenegativeimpactonfoamabilitywhenblendedwithAOSascomparedtothe'SurfX'surfactant.

(SakaiandKaneko2004;VanDerBent2014)intheirstudyalsofoundthesimilartrendthattheadditionofamphotericsurfactantdidnotimprovethefoamability.

Figure4showsA100foamgeneratedinsideaglasstube.

FoamstabilityFoamstabilitycanbedefinedasthetimeafoamfilmexistswithoutrupturing(SakaiandKaneko2004).

Itisgenerallyindicatedbyfoamhalf-life(timeneededforfoamtodecayhalfofitsoriginalfoam)(Yekeenetal.

2017b)Fig.

5showsthehalf-lifeofthebulkfoamexperiments,bothwithandwithouttheblendofLBat60°C,withlongerhalf-lifeindi-catingamorestablefoam.

AOSandLBblendof9:1gener-ated149.

68%morestablefoamascomparedtoindividualAOSsurfactantsolutions.

WhenAOSwasblendedwithLBatratioof7:3,itincreasedhalf-lifeby254.

91%.

When'SurfX'wasblendedwithLBat9:1,itshowedanimprovementinstabilitybyjust8.

92%;however,whentheblendratiowasincreasedandthe'SurfX'andLBwasblendedat7:3,therewasadecreaseinstabilityofabout39.

89%.

Incomparisonofindividualsurfactantsolution,X100hashigherfoamstabilityascomparedtoA100surfactantsolutiongeneratedfoam.

Thehalf-lifeofthesurfactantsolu-tionswasimprovedwhenLBwasblendedwiththeAOSand'SurfX'surfactants.

TheinfluenceonthestabilitywasmoreprofoundwithAOSsurfactantascomparedtothe'SurfX'surfactant.

AmongallthesurfactantblendedwiththeLB,'SurfX'neededlessamountofLBascomparedtotheAOS.

IncreasingtheratioofLBwith'SurfX'wasnotabletogreatlyimprovefoamstabilityatalltheratiostested.

TheA73surfactantsolutiongeneratedthemoststablefoamamongFig.

4A100foaminsideglasstubeFig.

5Foamdecayprofileofdifferentsurfactantsolutionswithandwithoutthefoambooster(LB)at60°C2664JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665allthesurfactantsolutiontested.

BasedonFig.

5,thefoamstabilityaccordingtohalf-lifeisrankedasthefollowingA73>X91>X100>A91>X73>A100.

Theincreaseinfoamstabilitywiththeblendofanamphotericsurfactanthasalsobeenreportedbyotherresearchers(Osei-Bonsuetal.

2015;Memonetal.

2016).

Ascomparedtoindividualcom-ponentsystems,theblendofdifferenttypeofsurfactantssynergisticallyexhibitbetterfoamingproperties(Bianetal.

2012;Memonetal.

2016).

ThisresultoftheincreaseinthefoamstabilitybyLBcanbeduetotheMarangonieffect,whichiscausedbyelectrostaticattractionbetweenanionicsurfactantandthecationicnitrogen(Domingo1996;SakaiandKaneko2004).

Gaoetal.

(2017)showedintheirstudyusingthesimulationforfoamstabilitythatthepresenceofamphotericsurfactantrelaxestherepulsionbetweentheheadgroupsofanionicsur-factants.

ThismechanismimprovedthefoamstabilityandcouldalsoberesponsiblefortheimprovedfoamstabilityinthepresenceofLBasobservedinthisresearch.

Moreover,itisanticipatedthatadditionofLBtothesolutioncouldincreasetheliquidviscosity,consequentlydecreasingtheliquiddrainagefromthefoamplateauborderswhichcauseshighresistancetofilmthinning,thusinfluencesthestabilityoffoam(Osei-Bonsuetal.

2015).

ConclusionInthiswork,whenblendedwithdifferentsolutions,theinfluenceoflaurylbetaineontheaqueoussolutionstabil-ity,foamabilityandbulkfoamstabilityinthepresenceofdivalentionsandatanelevatedtemperaturewerestudied.

Parameterssuchastheaqueoussolutionstability(phaseseparationandprecipitation),foamabilityandfoamsta-bilityweresystematicallyinvestigated.

Itwasfoundthatblendinglaurylbetainewithsurfactantaffectsthesolutionstability;notallthesolutionwasfoundstableastheratioofLBincreasedinthesurfactantsolutioninthepresenceofdivalentions.

Therewasanegativeimpactonfoamabil-itywhenlaurylbetainewasblendedwiththesurfactant.

A100andX100surfactantsolutionshadthebestfoamabilitytimeatboththetestedtemperatures.

Thefoamstabilityofthesolutionswasimproved;however,notallsolutionswereabletogeneratestablefoam.

'SurfX'individuallywasabletogeneratemorestablefoamascomparedtoAOSandwhenblendedwithlaurylbetaine.

Italsorequiredlessamountoflaurylbetainetogeneratemorestablefoam.

TheA73surfactantsolutiongeneratedthemoststablefoamfollowedbyX91surfactantsolution.

Thepresenceoflaurylbetaine(10%)in'SurfX'increasedthefoamstabilitybyapproxi-mately9%,whereasthepresenceoflaurylbetaine(30%)inAOSsurfactantsolutionincreasedthefoamstabilitybyapproximately255%.

Thesurfactantsolutionusedinthisstudythatgeneratedstablefoamwillbefurthertestedinporousmedia.

AcknowledgementAuthorswouldliketothankStepanCo.

andSolvayChemicalsCo.

forprovidingchemicalsusedinthisresearch.

AuthorswouldalsoliketothankInstituteofHydrocarbonRecovery,CentreofResearchofEnhancedOilRecovery(COREOR),Univer-sitiTeknologiPETRONASandtotheMinistryofHigherEducation(MOHE),(0153AB-L59)forsupportingthisresearchthroughfunda-mentalresearchGrantscheme.

OpenAccessThisarticleisdistributedunderthetermsoftheCrea-tiveCommonsAttribution4.

0InternationalLicense(http://creativecommons.

org/licenses/by/4.

0/),whichpermitsunrestricteduse,distribu-tion,andreproductioninanymedium,providedyougiveappropriatecredittotheoriginalauthor(s)andthesource,providealinktotheCreativeCommonslicense,andindicateifchangesweremade.

ReferencesBashevaES,GanchevD,DenkovNDetal(2000)Roleofbetaineasfoamboosterinthepresenceofsiliconeoildrops.

Langmuir16:1000–1013.

https://doi.

org/10.

1021/la990777+BianY,PennyGS,SheppardNCetal(2012)Surfactantformulationevaluationforcarbondioxidefoamfloodinginheterogeneoussandstonereservoir.

SPEImprovOilRecoverSymp.

https://doi.

org/10.

2118/154018-msChevallierE,DemazyN,CuencaA,ChabertM(2019)Correlationbetweenfoamflowstructureinporousmediaandsurfactantformulationproperties.

TranspPorousMedia.

https://doi.

org/10.

1007/s11242-018-01226-2ConnCA,MaK,HirasakiGJ,BiswalSL(2014)Visualizingoildis-placementwithfoaminamicrofluidicdevicewithpermeabilitycontrast.

LabChip14:3968–3977.

https://doi.

org/10.

1039/c4lc00620hCuiL(2014)Applicationoffoamformobilitycontrolinenhancedoilrecovery(EOR)process.

PhDdissertation,RiceUniversityDomingoX(1996)Betaines.

In:LomaxEG(ed)Amphotericsur-factants,2ndedn.

MarcelDekker,NewYork,p75FarajzadehR,AndrianovA,KrastevRetal(2012)Foam-oilinterac-tioninporousmedia:implicationsforfoamassistedenhancedoilrecovery.

AdvColloidInterfaceSci183–184:1–13.

https://doi.

org/10.

1016/j.

cis.

2012.

07.

002GaoF,LiuG,YuanS(2017)Theeffectofbetaineonthefoamstabil-ity:molecularsimulation.

ApplSurfSci407:156–161.

https://doi.

org/10.

1016/j.

apsusc.

2017.

02.

087HiraskiGJ(1989)Thesteam-foamprocess.

SocPetEng.

https://doi.

org/10.

2118/19505-paJensenJA,FriedmannF(1987)Physicalandchemicaleffectsofanoilphaseonthepropagationoffoaminporousmedia.

SPECalifor-niaRegionalMeeting.

SocietyofPetroleumEngineers,Ventura,California.

https://doi.

org/10.

2118/16375-MSJonesSA,vanderBentV,FarajzadehR,RossenWR,Vincent-BonnieuS(2016)SurfactantscreeningforfoamEOR:Correlationbetweenbulkandcore-floodexperiments.

ColloidsSurfPhysicochemEngAsp500:166–176.

https://doi.

org/10.

1016/j.

colsurfa.

2016.

03.

072KatgertG(2008)Flowoffoams.

DoctoralDissertation,UniversiteitLeidenLaskarisG(2015)Effectofsurfactantconcentration,watertreatmentchemicals,fattyacidsandalcoholsonfoambehaviorinporous2665JournalofPetroleumExplorationandProductionTechnology(2019)9:2659–2665mediaandinbulk.

Mastersdissertation,TUDelftUniversity,NetherlandLiRF,HirasakiG,MillerCA,MasalmehSK(2012)Wettabil-ityalterationandfoammobilitycontrolinalayered,2dhet-erogeneoussandpack.

SPEIntSympOilfChem.

https://doi.

org/10.

2118/141462-paMemonMK,ShukerMT,ElraiesKA(2016)Studyofblendedsur-factantstogeneratestablefoaminpresenceofcrudeoilforgasmobilitycontrol.

JPetExplorProdTechnol7:77–85.

https://doi.

org/10.

1007/s13202-016-0243-9Osei-BonsuK,ShokriN,GrassiaP(2015)Foamstabilityinthepres-enceandabsenceofhydrocarbons:frombubble-tobulk-scale.

ColloidsSurfAPhysicochemEngAsp481:514–526.

https://doi.

org/10.

1016/j.

colsurfa.

2015.

06.

023RafatiR,HamidiH,IdrisAK,MananMA(2012)Applicationofsus-tainablefoamingagentstocontrolthemobilityofcarbondioxideinenhancedoilrecovery.

EgyptJPet21:155–163.

https://doi.

org/10.

1016/j.

ejpe.

2012.

11.

010SakaiT,KanekoY(2004)Theeffectofsomefoamboostersonthefoamabilityandfoamstabilityofanionicsystems.

JSurfactantsDeterg7:291–295.

https://doi.

org/10.

1007/s11743-004-0314-xSinghR,MohantyKK(2016)Foamswithwettability-alteringcapabili-tiesforoil-wetcarbonates:asynergisticapproach.

SPEJ21:1126–1139.

https://doi.

org/10.

2118/175027-PAVanDerBentVJ(2014)Comparativestudyoffoamstabilityinbulkandporousmedia.

Mastersthesis,DelftUniversityofTechnologyWilsonAJ(1996)Experimentaltechniquesforthecharacterizationoffoams.

In:Prud'hommeRK,KhanSA(eds)Foams:theory,measurements,andapplication.

MarchelDekker,Inc,NewYork,pp243–272YekeenN,IdrisAK,MananMA,SaminAM(2017a)Experimentalstudyoftheinfluenceofsilicananoparticlesonthebulkstabil-ityofSDS-foaminthepresenceofoil.

JDispersSciTechnol38:416–424.

https://doi.

org/10.

1080/01932691.

2016.

1172969YekeenN,MananMA,IdrisAK,SaminAM(2017b)InfluenceofsurfactantandelectrolyteconcentrationsonsurfactantAdsorptionandfoamingcharacteristics.

JPetSciEng149:612–622.

https://doi.

org/10.

1016/j.

petrol.

2016.

11.

018YekeenN,MananMA,IdrisAKetal(2018)Acomprehensivereviewofexperimentalstudiesofnanoparticles-stabilizedfoamforenhancedoilrecovery.

JPetSciEng164:43–74.

https://doi.

org/10.

1016/j.

petrol.

2018.

01.

035Publisher'sNoteSpringerNatureremainsneutralwithregardtojurisdictionalclaimsinpublishedmapsandinstitutionalaffiliations.

- test7po.com相关文档

- 转化7po.com

- type7po.com

- 7po.comvivo手机怎么获得R00t

Virtono:€23.7/年,KVM-2GB/25GB/2TB/洛杉矶&达拉斯&纽约&罗马尼亚等

Virtono最近推出了夏季促销活动,为月付、季付、半年付等提供9折优惠码,年付已直接5折,而且下单后在LET回复订单号还能获得双倍内存,不限制付款周期。这是一家成立于2014年的国外VPS主机商,提供VPS和服务器租用等产品,商家支持PayPal、信用卡、支付宝等国内外付款方式,可选数据中心包括罗马尼亚、美国洛杉矶、达拉斯、迈阿密、英国和德国等。下面列出几款VPS主机配置信息,请留意,下列配置中...

轻云互联(19元)香港高防云服务器 ,美国云服务器

轻云互联成立于2018年的国人商家,广州轻云互联网络科技有限公司旗下品牌,主要从事VPS、虚拟主机等云计算产品业务,适合建站、新手上车的值得选择,香港三网直连(电信CN2GIA联通移动CN2直连);美国圣何塞(回程三网CN2GIA)线路,所有产品均采用KVM虚拟技术架构,高效售后保障,稳定多年,高性能可用,网络优质,为您的业务保驾护航。活动规则:用户购买任意全区域云服务器月付以上享受免费更换IP服...

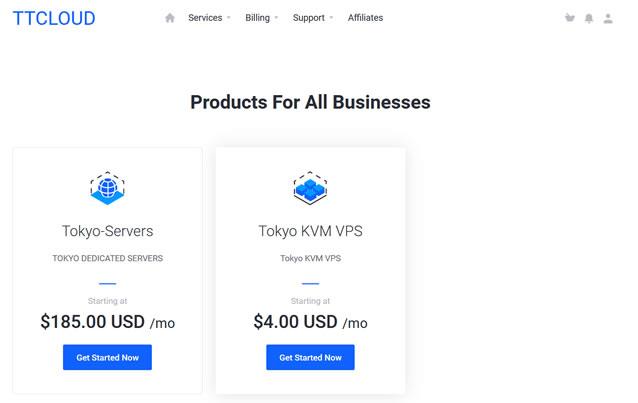

TTcloud(月$70)E3-1270V3 8GB内存 10Mbps带宽 ,日本独立服务器

关于TTCLOUD服务商在今年初的时候有介绍过一次,而且对于他们家的美国圣何塞服务器有过简单的测评,这个服务商主要是提供独立服务器业务的。目前托管硬件已经达到5000台服务器或节点,主要经营圣何塞,洛杉矶以及日本东京三个地区的数据中心业务。这次看到商家有推出了新上架的日本独立服务器促销活动,价格 $70/月起,季付送10Mbps带宽。也可以跟进客户的需求进行各种DIY定制。内存CPU硬盘流量带宽价...

7po.com为你推荐

-

特朗普取消访问丹麦特朗普出国访问什么飞机护送?中老铁路中长铁路的铁路的新中国历史地图应用看卫星地图哪个手机软件最好。psbc.comwww.psbc.com怎样注册rawtools闪迪32Gsd卡,无法格式化,显示只有30M,并且是raw格式。如何恢复?丑福晋八阿哥胤禩有几个福晋 都叫啥名儿呀porndao单词prondao的汉语是什么ip在线查询通过对方的IP地址怎么样找到他的详细地址?javbibinobibi的中文意思是?sodu.tw台湾的可以看小说的网站