latestwisediskcleaner

wisediskcleaner 时间:2021-04-01 阅读:()

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite125nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite1DriveSystemsSeries51BGServoBevel-GearUnitsBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite225nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite2ContentsCompanyAddress.

3General.

3Whoshouldstudytheseinstructions3Safetynotes.

3Othersignsandsymbols.

3Exclusionofliability.

4Modifications,conversions.

4ECMachineryDirective.

4Technicalchanges4Properuse.

4Improperuse5QualifiedPersonnel5Generalsafetyinstructions5Shortdescription.

6Itemnumber7Tighteningtorques.

9Checklist-start-up.

9Start-up/operation.

10Maintenance.

11Shaftsealingrings:11Maintenanceintervals12Changingthegearoil.

12Cleaning.

14Mountinginstruction15Preparingtheinstallation.

15Installationofbevel-gearunits:15Mountingtheoutputdriveshaft(Versionwithshrink-disc)16Mountingtheoutput-drivepinionshaftBG50(Versionwithkey)18Mountingtheoutput-drivepinionshaftBG63andBG80(Versionwithkey)19Mountingtheclutchonthemotorshaft20Mountingthemotor21Transportandhandling.

23Storage.

23Failurelist(Troubleshooting)24Disposal.

25CAUTION!

Theobservanceoftheseoperationandmaintenanceinstructionsispre-requisitefortheundisturbedoperationandtheacceptanceofliabilityforpossibledefects.

Thereforestudytheoperationandmaintenanceinstructionsbeforestartingtousethegearunit.

Makesurethattheoperationandmaintenanceinstructionsaremadeaccessibletotheassemblypersonnelinlegiblecondition.

Observeanynational/regionalregulationsconcerningsafetyandpreventionofac-cidents.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite325nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite3CompanyAddressATLANTAAntriebssystemeTelefon:+49(0)7142-7001-0E.

SeidenspinnerGmbH&Co.

KGTelefax:+49(0)7142-7001-99Adolf-Heim-Strae16/18E-Mail:info@atlantagmbh.

de74321Bietigheim-BissingenInternet:http://www.

atlantagmbh.

deGeneralWhoshouldstudytheseinstructionsTheseinstructionsareaddressedtoallpersonsinstalling,operatingormaintainingtheseries51BGservobevel-gearunits.

YoumustnotusetheSeries51BGservobevel-gearunitsbeforehavingreadandunderstoodtheseoperatingandmaintenanceinstructions.

Pleasegivethesafetyinstructionsalsotootherpersons.

SafetynotesThefollowingsignalsymbolsandwordsareusedintheinstructionstowarnyouand/orinformyouofsomething.

warnsyouabouthighinjuryhazardswarnsyouaboutpossibleinjuryhazardswarnsyouaboutminorinjuryhazardsand/ordamagehazardsEnvironmentallyhazardous-warnsyouaboutapollutionhazardfortheenvironmentTransportwarnsyouofinjuryhazardswhentransportingandhandlingbulkyobjectsOthersignsandsymbolsbyan"instructiontoact"youareaskedtodosomethingbyahint"youareinformedofapossiblesimplificationorimprovement#Maintenance:suggestsoptimaloperationWhenoperatedinareaswithexplosionhazardtheinstructionsidentifiedbythesym-bolaretobeobserved.

ThesewerepreparedonthebasisoftheignitiondangerratingKGA114.

Thissymbolreferstothenameplate.

Thestoragesymbolindicateshowthebevel-gearunitsshouldbestored.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite425nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite4ExclusionofliabilityThemanufacturerwillnotacceptliabilityfordamagesorinjuriesresultingfromimproperuseorhandlingoftheseries51BGservobevel-gearunits.

Impropermanipulationsandotheractsnotinaccordancewiththeseinstructionsimpairthequal-ityoftheproduct.

ThiswillleadtotheexclusionofwarrantyclaimsagainstATLANTAAntrieb-ssystemeE.

SeidenspinnerGmbH&Co.

KG.

Modifications,conversionsModificationsand/orconversionsofthegearunitarenotpermissibleunlessexpresslyapprovedbyATLANTAinwriting.

ECMachineryDirectiveAsdefinedbytheECMachineryDirective98/37ECthegearunitisnotconsideredanautono-mousmachinebutacomponenttobeinstalledinmachines.

WithinthepurviewoftheECdirectivetheunitmustnotbeoperatedunlessthemachineintowhichthisproductisinstalledfulfillstherequirementsofthedirective.

TechnicalchangesATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KGreservetherighttomaketechni-calchangestoimprovetheproduct.

ProperuseTheATLANTAseries51BGservobevel-gearunitmayonlybeusedforspeedandtorqueconversioninmachinesandmechanicalequipmentunderatmosphericpressureconditions.

Itmustnotbeusedoutdoors.

Thepermissibleinputspeedandoutputtorqueaswellasthepermissibleadditionalloadsmustnotbeexceeded.

ThelayoutinstructionsintheAtlantacataloguemustbeobserved.

Themaximumtorquespermittedarelistedinourcatalogueorourwebsite:http://www.

atlantagmbh.

deThegearboxmustnotbeusedincombinationwithcombustionengines–dangerofoverheating,inadmissibleshockloading!

Thegearunitisdesignedforinputdriveviabevel-gearshaftwithATLANTAE-servospecialclutchorATLANTAspecialclutchTheinputdriveviabevel-gear(hollowoutputshaft)maybechosenonlyafterconsultingATLANTA.

Theefficiencyratingindicatedisbaseduponinputdriveviathesplinedshaft.

Thegearunitisnotself-braking.

Thegearunitmustnotbeusedoutdoorsorunderwater.

Thesurfacetemperatureofthegearboxmustnotexceed80°Cduringoperation.

WhenusedinareaswithexplosionhazardthetemperatureofBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite525nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite5thehousingmustnotexceed65°C.

Ifnecessary,measurethesurfacetemperatureandwarnorswitchoffwhenitexceeds65°C.

Thegearunitisdesignedforintermittentoperation(S3acc.

toDINEN60034-1).

Continuousoperation(S1acc.

toDINEN60034-1)isnotpermissiblewithoutthemanufac-turer'swrittenapproval.

Continuousoperationisdefinedbythedutycycle.

Ifitexceeds30%orislongerthan20minutes,itisconsideredcontinuousoperation.

Whenusedinareaswithexplosionhazardtheinstructionsidentifiedbythesymbolaretobeobserved.

ImproperuseJWhenevertheabovementionedlimitsareexceeded(especiallyhighertorqueorspeed),thisshallbeconsideredimproperusewhichisforbidden.

Itisforbiddentooperatethegearunitif:itisnotcorrectlymounted(e.

g.

fasteningofthemotor),itisnotproperlyinstalled(e.

g.

fixingscrews),thegearunitisverydirty(e.

g.

dustdeposits)thereisnosufficientlubrication.

QualifiedPersonnelSomeresidualdangerforpersonsandobjectsmayemanatefromtheseries51BGservobevel-gearunit.

Thereforeonlyskilledandtrainedpersonnelbeingawareofpossiblerisksmaycarryoutmounting,installation,start-up,service,andmaintenancework.

Thepersonnelmusthavethenecessaryqualificationfortheworktobedoneandmustbefamiliarwithmounting,installation,startingupandoperatingtheproduct.

Inadditiontheymustcarefullyread,understandandobservetheoperatinginstructionand,inparticular,thesafetyinstructions.

Thefollowingworksshouldalsobecarriedoutonlybyqualifiedpersonnel:Transport,storage,erection/installation,connection,start-up,service,maintenanceGeneralsafetyinstructionsWedonotclaimthesesafetyinstructionstobecomplete.

IncaseofquestionsorproblemspleasecontactATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KG.

Thegearunitincorporatesthelatesttechnologicaldevelopmentatthetimeofdeliveryandcanbeprincipallyregardedassafetooperate.

Impropermanipulationsmayleadtoinjuriesanddamages.

Makesurethatthegearunitisonlyinstalled,serviced,ordisassembledbyspeciallytrainedskilledpersonnel.

Foreignmatterflungaboutmaycauseseriousinjurie.

Makesurethatnoforeignmatterortoolsarenearthegearunitbeforestartingoperation.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite625nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite6Contactwithhotsurfacesmaycauseburns.

Nevertouchgearunitswhentheyhavehighoperatingtemperatures,orusesuitableprotec-tiveequipment(e.

g.

gloves).

Rotatingpartsmaycauseinjuries.

Pulling-inrisk!

Keepsufficientdistancetorotatingmachineparts.

Neverinstalloroperatedefectiveproducts.

Incaseofdamagepleasecomplainimmediately.

ShortdescriptionTheATLANTABGservobevelgearunitwasdevelopedforusewiththree-phaseACandDCservomotors.

Itfeaturesalow-clearancegearing.

Thelight-metalcasingensuresoptimalheatdissipation.

Robustbearingsandanexcellentstiffnesspermitthetransmissionofhightorquesandadditionalforces.

Thegearunitissuppliedtest-run,tightness-checkedandthusreadyforoperation.

Thegearunitisavailablewithdifferentreductionratios.

Withinonegearboxsizeanddesignallcomponents,exceptforthesetofwheels,arethesame.

Thelast2digitsoftheitemnumberstandforthenominalreductionratio.

Theexactreductionratiocanbeseenfromtheta-blebelow.

Itemno.

ActualgearreductionApplicableto51xxx0519/4=4,75allsizes51xxx0727/4=6,75allsizes51xxx0939/4=9,75allsizesThisgearunitisavailablewith2outputvariations:hollowoutputshaftforkeyconnectionshollowoutputshaftforclampedconnectionsBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite725nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite7ItemnumberTheitemnumberiscomposedasfollows:ExampleBGservobevel-gearunitBG=80mm,i=4.

75versionwithkeyorshrink-discIdentificationThegearunitisidentifiedbyanameplatecontainingthegearboxtype,thegearratio,themax.

performanceforS3operation,themax.

speedforS3operation,theassemblydate,andtheserialnumberofthegearunit.

TypeGearratioMax.

performanceforS3operation[kW]Max.

speedforS3operation[min-1]Mass[kg]Serialnumber51050055715005BG-ServoKegelrad-getriebeBG-ServoBevelgearunitBG-ServoKegelrad-getriebeBG-ServoBevelgearunitPafeder-AusführungKeywaydesignSchrumpfscheiben-AusführungShrink-discdesignBaugreBG=80Construction-sizeBaugreBG=80Construction-sizeGehuse-IdentnummerOrdercodeofhousingGehuse-IdentnummerOrdercodeofhousingbersetzungi=4,75Ratiobersetzungi=4,75RatioBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite825nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite8Aseparateoilratingplatespecifiesthetypeofoil:Whenusedinareaswithexplosionhazardthegearunitmustbeadequatelyidentifiedbyameansofanameplate.

Onlythenitmaybeusedinsuchareas:BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite925nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite9TighteningtorquesAllscrewconnectionsforwhichtighteningtorquesarespecifiedareprincipallytobetightenedandcheckedwithacalibratedtorquewrench.

Thetighteningtorquescanbetakenfromtablesinrelevantbooks.

Shouldscrewsbeemployedacc,toDIN912,youcanusethefollowingtable:Forthecountersunkholes:Whenapplyingtorquesacc.

toyourowncompanystandard,whichallowstheutilizationof90%oftheyieldpointofthescrew,asuitablewasher/bushingshouldbeused.

Hexag.

socket-headscrewsDIN912Strengthclass8.

8/aluminiumhousingM5M6M8M10M12M16TighteningtorqueinNm*)3,58,918.

84045117Tighteningtorqueinlbfin*)31781663543981035.

5Forthethreadedholes::(Effectivelengthofthreadmin.

1.

5xdnenn/bearingsurfacesteelwithmin.

pG>300N/mm2)Hexag.

socket-headscrewsDIN912Strengthclass8.

8M5M6M8M10M12M16TighteningtorqueinNm*)5,59,5234680195Tighteningtorqueinlbfin*)48842034077081725*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighteningtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusable.

Checklist-start-upBeforestartingupWhathastobecheckedCheckedDelivery:ArethesuppliesinconformitywiththeconsignmentnoteAnytransportdamageshouldbereportedimmediatelytothecarrier.

Obviousdefects/incompletenessshouldbereportedimmediatelytoATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KG.

Applicationinareaswithexplosionhazard:Arethefollowingdataonthenameplateofthegearboxes/motorsinconformitywiththepermissibleEx"applicationareaonthesite–Explosiongroup–Category–Zone–Temperatureclass–Max.

surfacetemperatureAmbienttemperature:Istheambienttemperaturerangeacc.

tothedataonthelubricanttableobservedThemax.

ambienttemperatureof40°Cmustnotbeexceededthrough-outthewholeoperatingtime.

thetemperaturemustnotfallbelowthemin.

ambienttemperatureof-10°Cthroughoutthewholeoperatingtime.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1025nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite10Ventilation:IssufficientventilationofthegearboxensuredInputandoutputdriveelements:Areallinputandoutputdriveelementstobemountedsuitableforthespecificex"protectionuseNameplateinformation:ArethedataonthegearboxnameplatenotexceededDuringstart-upWhathastobecheckedCheckedEnvironment:Itmustbeensuredthattherearenoatmospheres,oils,acids,gases,vapours,orcombustibledustsaroundwhichmayexplode!

Temperaturemeasurement:Thetemperaturemustbemeasuredafter3hoursofoperationundermax.

operatingloadconditions!

Thetemperaturemeasurementsshallbetakenintheinputareainplaceswhichareprotectedfromthecoolingaircurrent.

Itisadvis-abletomeasureinvariousplacesinordertodeterminethemaxi-mum.

Theabsolutetemperatureof80°Conthesurfaceofthegearboxmustnotbeexceededsothatthethermalstressonshaftsealsandlubricantsiskeptlow;thishasapositiveinfluenceupontheservicelife.

Start-up/operationMakesurethatthefollowingpreconditionsfortheoperationarefulfilled:Thecontrolandprotectivesystemsmustnotbeshutoff.

Thisappliesalsofortrialrunsandstart-upoperation.

Thegearunitsmustnotbeoperatedunderthefollowingambientconditions:oExplosiveatmosphere,(exceptionCEII3GT4/II3DT130°C)ooils,oacids,ogases,(exceptionCEII3GT4/II3DT130°C)ovapours,oradiation.

Dependinguponthelubricantsusedtheambienttemperatureshouldbebetween10°Cand+40°C.

Iftheambienttemperatureslieoutsidethepermissiblerange,getintocontactwithATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KG.

Thegearunitsmustnotbeoperatedunlesssufficientventilationisensuredinordertoavoidanyheatcongestion.

Whenusedinareaswithexplosionhazard,theoperatormustensurethatthesurfacetemperatureofthegearboxdoesnotexceed65°C.

;ifnecessary,controlthesurfacetemperatureofthehousing.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1125nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite11Thesurfaceofthegearboxcanreachtemperaturesofmorethan65°C.

duringoperationandcancauseburns.

Theper-soninstallingthegearunitmusttakecarethatpersonscannotbeinjuredduetohotsurfaces.

Rotatingpartscancatchpiecesofclothing,hair,andmem-bersofthebodyandcaninjurepersons.

Thepersoninstallingthegearunitmusttakecarethatpersonscannotbeinjuredbyrotatingparts.

MaintenanceAccidentalstartingofthegearunitwhilemaintenanceworkisbeingcarriedoutcanleadtoseriousaccidents.

Makesurethatnobodycanstartthegearunit,whilemaintenanceworkisbeingperformed.

Evenshortoperationofthegearunitwhilemaintenanceworkisbeingcarriedoutcancauseaccidents,ifthesafetydevicesareshutoffandinoperative.

Makesurethatallsafetydevicesaremountedandoperative.

Shaftsealingrings:Shaftsealingringssealthegapbetweenthehousingandtherotatingshafts.

Theyarewearingpartswhichhavetobereplacedwhentheyreachthepermissiblelimitofwear.

Theservicelifeofshaftsealingringsisinfluencedbyamultitudeofparameters.

Theseareamongothers.

:peripheralspeedatthesealingliptemperatureinternalpressureinthegearboxviscosityoflubricantchemicalanalysisandadditivationoflubricantsmountingsituation(lubricantsupplytothesealinglip)particlesand/ormetallicfinesinthelubricantmaterialoftheshaftsealingringexternalpollutionThismultitudeofinfluencingparametersmakeitpracticallyimpossibletopredictthepreciseser-vicelifewithoutmakingexperimentssimulatingtherespectiveapplication.

Astheservicelifeoftheshaftsealingringsissubjecttotheabovementionedfluctuations,it.

.

isabsolutelynecessarytocheckthematregularintervals.

Onlyregularcheckscanpreventunnoticedlossoflubricantinthegearbox.

Whenevertheshaftsealingisreplacedyoushouldalsochecktherunningsurfaceofthelipsofthesealontheshaft.

Ifseizuremarksarevisible,theshaftmustberepairedorreplaced.

Alterna-tivelyitispossibletoinserttheshaftsealingringinaslightlyaxiallydisplacedpositionsothatthelipofthesealrunsinapracticallynewplaceBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1225nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite12MaintenanceintervalsProvidedthatthegearunitsareusedproperlyasdescribedinthecatalogue,theseries51BGservobevel-gearunitsaredesignedandbuiltfor12,000hofoperationexceptforwearingpartssuchasthebearingsandtheshaftsealingrings.

Thefollowingmaintenanceworksshouldbeperformedfortheseries51BGservobevel-gearunits.

IntervalWhatshouldbedoneEvery2000machinehours,butatleasteverysixmonthsChecktherunningnoisetodetectpossibledefectsinthebearingsInspectthemotorflangesforleakageInspectthesealsforleakage.

Shouldanyleakagebede-tected,pleasecontactus.

After5000…8000hours,butafter3yearsatthelatestReplacetheshaftsealingringsChangingthegearoilAsufficientamountoflubricantisabsolutelynecessaryforsafeoperation.

Thelubricantensuresthatdryrunningandconsequentlyexcessivelyhighsurfacetemperatures,wear(play),orme-chanicsparkingispreventedinthemetalliccontacts.

Themaindangerisanunnoticedlossoflubricant.

Thereforethegearunitsmustberegularlycheckedforlossoflubricant.

ATLANTAEservobevel-gearunitsarefilledwithsyntheticpolyglycoloil.

Underthefollowingpreconditionsthisisalifetimelubrication:ThelayoutofthegearunitisstrictlyinaccordancewiththeguidelinesgivenintheATLANTAcatalogue(www.

atlantagmbh.

de).

Thegearunitisexclusivelyoperatedwithinthepermissiblecharacteristicandlimitvalues(www.

atlantagmbh.

de).

Theoperatorchecksthegearunitregularly(every2weeks)forlossofoil.

Thesurfacetemperaturemustnotexceedmax.

80°Cduringoperation.

Inthecaseofoperationwithmostlylowinputspeeds(peripheralspeedofthebevelgearv40°CThemostsuitablepointforcontrollingthemax.

permissiblesurfacetemperatureofthehous-ingisintheareaoftheinput-sidebevel-gearshaftbearings.

Theverticalarrangementoftheshaft(inputoroutputverticallydownward)isonlypermissiblewithanoillevelmonitorstoppingthegearunitincaseofasuddenlossofoil.

Mountingtheoutputdriveshaft(Versionwithshrink-disc)Fortheoutputdriveshaftwerecommendtoleranceh6(DINISO286).

Thematerialmusthaveaminimumyieldpointof385N/mm2.

IfyouhaveboughttheoutputdriveshaftfromATLANTAandifitisnotsuppliedalreadymounted,werecommendtoproceedasfollows:Cleantheseatofthehollowshaftandoilitslightly(donotusegrease).

Wipeoffanyexcessoilwitharag.

Slidetheshrink-discontothehollowshaft.

Donottightenthescrewsbeforehand!

Cleantheshankoftheoutputdriveshaftandoilitslightly.

Wipeoffanyexcessoilwitharag.

abutmentscrewingsurfaceBevel-gearunitlateralforcesBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1725nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite17Pushtheoutputdriveshaftintotheborerightuptothestop.

Attachtheshrink-discbyevenlytighteningthescrewsoneaftertheother(notcrosswise).

Makesurethatthetwoclampingdiscsareplaneparallel.

Severalpassesarenecessaryuntilthescrewsaretightenedtothespecifiedtorqueacc.

tothetablebelow.

OrdercodeTighteningtorque*)808403612Nm808505012Nm808606212Nm*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighten-ingtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusable.

Soilingmayimpedethetransmissionofthetorque.

Donotdisassembletheshrink-discclampingsetbeforemountingitIfthegearunitiscleanedinthesealingareawithacleansingagentapprovedbyATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KGthesurfacescleanedmustbeprotectedagainagainstcorro-sion.

Theforcesoftheshrink-disccandeformthehollowshaft.

Alwaysinstallthemachineshaftbeforetighteningtheclampingscrewsoftheshrink-disc.

Slantingtheshaftsmaycausedamage.

MakesurethatthehollowshaftandthemachineshaftarealigneWhenusedinareaswithexplosionhazardimproperinstallationmayleadtoinadmissiblyhightemperatures.

Checkthetighteningtorquesandaxialfixingafter10hoursunderoper-atingconditions.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1825nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite18Mountingtheoutput-drivepinionshaftBG50(Versionwithkey)Unlesstheoutputpinionshaftcomesalreadyfullyassembled,werecommendtoproceedasfol-lows:CleantheseatofthehollowshaftandrubwithMoS2-powderorgrease(reducesfrettingcorrosion).

Insertthelockingwasherintotherecessofthehollowshaft.

.

Insertthelockingwasherfromtheoppositesideuptothestopinsidethehollowshaft.

.

Connectthemountingplateandtheoutputshaftbymeansofthescrew.

Securethescrewusingsuitableadhesive(e.

g.

Loctite243).

*)Drylubricant:Improvestheslidingpropertiesofmachinepartsandreducesfrictionandwearwithinawidetemeperaturerange;minimumfrictionwithmaximumloadcapacit.

GearboxwithoutoutputshaftInsertpinionshaftMountretainingdisk/lockscrewandtightenTheretainingring,washerandscrewsuppliedwiththedriveshaftservefortheaxialfixationoftheinputdrivingshaft.

ForgearboxessizeBG50anadditionalwasher25109001isrequiredwhichreplacesthetwoitemsretainingring+lockingwashersuppliedtogetherwiththedrivingshaft.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1925nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite19Mountingtheoutput-drivepinionshaftBG63andBG80(Versionwithkey)Unlesstheoutputpinionshaftcomesalreadyfullyassembled,werecommendtoproceedasfol-lows:CleantheseatofthehollowshaftandrubwithMoS2-powderorgrease(reducesfrettingcorrosion).

Inserttheretainingringintotherecessofthehollowshaft.

Pushintheoutputshaftrightuptothestop.

Insertthelockingwasherfromtheoppositesideuptothestopinsidethehollowshaft.

Connectthemountingplateandtheoutputshaftbymeansofthescrew.

Securethescrewusingsuitableadhesive(e.

g.

Loctite243)*)Drylubricant:Improvestheslidingpropertiesofmachinepartsandreducesfrictionandwearwithinawidetemeperaturerange;minimumfrictionwithmaximumloadcapacit.

GearboxwithoutoutputshaftInsertSpringInsertpinionshaftMountretainingdisk/lockscrewandtightenHexagonsockethead-screwsDIN912strengthrating8.

8/lockingwasherM5M8M12M16TighteningtorqueinNm5.

52380195Tighteningtorqueinlbfin48.

5203.

57081726*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighteningtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusableSlantingtheshaftsmaycausedamage.

Makesurethatthehollowshaftandthemachineshaftarealigned.

Mountthemachineshaftinthehollowshaftwithoutusingforce.

Nevertrytomountitbymeansofknockingitin.

Useonlysuitabletoolsanddevices.

Whenusedinareaswithexplosionhazard,improperinstallationmayleadtoinadmissiblyhightemperatures(seeignitiondangerratingacc.

toKGA114).

Checkthetighteningtorquesandtheaxialfixingafter10hworkunderoperatingconditions.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2025nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite20655XXXX654XXXXMountingtheclutchonthemotorshaftATLANTAEservospecialclutch655XXXXorATLANTAspecialclutch654XXXXTheclutchissuppliedpre-assembled.

VBeforemountingtheclutchonthemotorshaftcleanallcontactsur-facesandcoatthemwithathinoilfilm(nogrease).

AnyexcessoilshouldbewipedoffwitharagRubtheDIN5480profileoftheclutchwithMoS2powderorgrease(reducesfrettingcorrosion)Ifthemotorshafthasakey,itshouldberemoved.

Slidetheclutchontothemotorshaftasfarasspecifiedinthecata-logueasX1"(655XXXX)and/orrightuptothestop(654XXXX/shoulderorretainingring).

Inthecaseofclutch655XXXXintermediatesleevesmaybeusedinordertoreachthemotor-shaftdiameter.

Insuchacasetheslotintheintermediatesleevemustbealignedwiththeslotintheclutchbody.

Slightlytightentheclampingscrews.

Tightenscrewsuniformlybyturningthemalternately(crosswisewith654XXXX).

.

Checkclutchfortruerunningatthereferencediameter(fr<0.

04mm).

Severalpassesarenecessaryuntilthescrewsaretightenedtothetighteningtorquespeci-fiedinthetablebelow.

Makesurethatthewidthofthegapbetweenclutchandpressuresurfaceremainsuniform.

Checkatreferencediameterfortruerunning.

OrdercodeofclutchTighteningtorque*)OrdercodeofclutchTighteningtorque*)6551xxx7Nm62lbfin6543xxx7Nm62lbfin6553xxx7Nm62lbfin6544xxx10Nm88,5lbfin6554xxx10Nm88,5lbfin6546xxx10Nm88,5lbfin6555xxx25Nm221lbfin6547xxx25Nm221lbfin*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighten-ingtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusable.

Whenusedinareaswithexplosionhazard,improperinstallationmayleadtoinadmissiblyhightemperatures(seeignitiondangerratingacc.

toKGA114).

Checkthetighteningtorquesandtheaxialfixingafter10hrsworkunderoperatingconditions.

Whenusedinareaswithexplosionhazard,usecorrosion-protectedscrews.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2125nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite21MountingthemotorCleanflangesurfaceandcenteringshoulderonmotorandgearbox.

Slidethemotorwithcouplingmountedontotheteethoftheinputdriveshaftandintothegearcenteringpiecesothattheplanesurfacestouch.

Ifnecessary,rotatethemotoraroundthemotoraxleuntiltheclutchandtheinputshaftteethmesh.

.

Themotormustslideoneasily.

Theremustnotbeanygapbetweenthemotorandthegearboxflange.

Mountingmotorshavinglongershaftsthanpermissiblefortherespectivegearunitleadstotensionswhichdamagethemotorandthegearunit.

Checktheinterferingedgesbymeasuringoutorbycheckingthedimensionaccordingtoourcataloguedataandthemotormanufacturer'sdata.

Screwmotorandgearboxtogether.

Hexagonnutsorscrewsaretobetightenedtothespeci-fiedtorqueandsecured.

Thecorrecttighteningtorquecanbeseenfromtherespectiveta-bles.

Inthiscontextitisparticularlyimportanttopayspecialattentiontothestrengthclassofthescrewandthematerialofthesupportingsurfaces.

Themotorcanbemountedoptimallycenteredbypositioningthegearboxinsuchawaythatthebevel-gearshaftisstandingupvertically.

Usescrewswithaneffectivelengthofatleast1.

6xthreaddiameter.

Whenusedinareaswithexplosionhazard,usecorrosion-protectedscrewsMounttheclutchonthemotorshaftandfastenasdescribedCleanmotorandclutchsurfacesBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2225nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite22Screwmotortogearbox,Usepropertighteningtorqueforscrews*)Drylubricant:Improvestheslidingpropertiesofmachinepartsandreducesfrictionandwearwithinawidetemeperaturerange;minimumfrictionwithmaximumloadcapacity.

CleanscrewingsurfacesofmotorandgearboxandrubwithMoS2*)powderorgreaseBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2325nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite23TransportandhandlingTherearenospecialholesorthreadsprovidedfortransportingandhandlingthegearunit.

Thereare,however,numerousfixingthreadsavailableinthegearhousingpermittingtoscrewineye-boltssothatitispossibletohandlethegearboxsafely.

Observeallsafetyregulationsinconnectionwithtransportandhandlingusingliftinggear.

Makesurethattheloadishandledandsetdownslowlyandcarefully.

GearboxsizeWeightwithoutattachmentsBG50≈3,2kgBG63≈6kgBG80≈8kgStorageIfthegearunitisnotinstalledimmediatelyafteritsdelivery,thefollowingmeasuresaretobetaken:Storethegearunitwithhorizontalhollowoutputshaftandhorizontalinputdriveshaft(wormshaft)ontopinsuchawaythat-exceptforthesupportingsurface-itcannotcomeintocontactwithanyotherobjectsProtectthegearunitsfromdetrimentalenvironmentalinfluences(highairhumidity,saltyair,aggressivegases;UVlight,electricwelding;dust;dirt,shocks;temperaturefluctuations;[0°Cto+30°C],etc.

).

Connectingparts,e.

g.

clutchoroutputshaft,aretobestoredseparately.

Protectthesteelpartsagainstcorrosion.

Aslogisticsprincipleforstore-keepingwerecommendthefirstin–firstout"principle.

Occasionallyturningtheinputshaftofthegearunitwillfacilitatethestart-upThemax.

storagetimeundersuchconditionsis2years.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2425nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite24Failurelist(Troubleshooting)Youshouldtakeremedialmeasuresatonce,ifyougetawareofoilloss,increasedoperatingnoises,orincreasedoperatingtemperatures.

Anydisturbancesoccurringduringthewarrantyperiodrequiringtherepairofthegearunit,mayonlyberemediedbyATLANTA.

Werecommendtoaskforourassistancealsoaftertheexpirationofthewarrantyperiod.

Alwaysshutdownthegearboxduringtheeliminationofdisturbances.

Securethedrivingunitagainstinadvertantstarting.

Postanoticeattheswitchingposition.

ProblemPossiblecauseRemedyLayouttoweak;Speed/torquetoohighCheckthetechnicaldataMotorheatsupthegearunitChecktheattachmentcircuit,replacethemotor,orprovideaninsulationbetweenmotorandgearunitAmbienttemperaturetoohighEnsureadequatecoolingIncreasedoper-atingtempera-tureDutycycletoolongVerifythelayoutDefectivebearingDefectivetoothsystemPleasecontactusThefixingofthegearunithasloosened.

Tightenscrews/nutswiththespecifiedtight-eningtorque.

Replacedefectivescrews/nuts.

Increasedopera-tingnoiseAdjustmentofcontroller.

Checktheservo-motorparametersLeakageGetintocontactwithus.

LossofoilApparentleakageAtemporaryleakageduetomuchgreasebetweensealinglipandprotectivelip.

Thesurplusgreasecanpenetrateoutsideasanapparentleakage.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2525nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite25DisposalPleaseobservethenationalregulations!

Ifrequired,disposeoftheindividualcomponentsseparatelydependingontheirnatureandanyexistingspecificnationalregulations,e.

gas:Steelscrapogearwheelsoshafts(hollowshafts)oantifrictionbearingsocastironpartsoclutchesAluminiumscrapohousingelementsoadaptorelementsBronzescrapobevelgear(separatedfromhollowshaft)CollectwasteoilanddisposeofasdirectedATLANTAdoesnotacceptliabilityforanydamagetothetransmissionoranyconsequentialdamage,iftheseinstructionsarenotobserved.

93AbteilungTBSeite125nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite1DriveSystemsSeries51BGServoBevel-GearUnitsBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite225nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite2ContentsCompanyAddress.

3General.

3Whoshouldstudytheseinstructions3Safetynotes.

3Othersignsandsymbols.

3Exclusionofliability.

4Modifications,conversions.

4ECMachineryDirective.

4Technicalchanges4Properuse.

4Improperuse5QualifiedPersonnel5Generalsafetyinstructions5Shortdescription.

6Itemnumber7Tighteningtorques.

9Checklist-start-up.

9Start-up/operation.

10Maintenance.

11Shaftsealingrings:11Maintenanceintervals12Changingthegearoil.

12Cleaning.

14Mountinginstruction15Preparingtheinstallation.

15Installationofbevel-gearunits:15Mountingtheoutputdriveshaft(Versionwithshrink-disc)16Mountingtheoutput-drivepinionshaftBG50(Versionwithkey)18Mountingtheoutput-drivepinionshaftBG63andBG80(Versionwithkey)19Mountingtheclutchonthemotorshaft20Mountingthemotor21Transportandhandling.

23Storage.

23Failurelist(Troubleshooting)24Disposal.

25CAUTION!

Theobservanceoftheseoperationandmaintenanceinstructionsispre-requisitefortheundisturbedoperationandtheacceptanceofliabilityforpossibledefects.

Thereforestudytheoperationandmaintenanceinstructionsbeforestartingtousethegearunit.

Makesurethattheoperationandmaintenanceinstructionsaremadeaccessibletotheassemblypersonnelinlegiblecondition.

Observeanynational/regionalregulationsconcerningsafetyandpreventionofac-cidents.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite325nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite3CompanyAddressATLANTAAntriebssystemeTelefon:+49(0)7142-7001-0E.

SeidenspinnerGmbH&Co.

KGTelefax:+49(0)7142-7001-99Adolf-Heim-Strae16/18E-Mail:info@atlantagmbh.

de74321Bietigheim-BissingenInternet:http://www.

atlantagmbh.

deGeneralWhoshouldstudytheseinstructionsTheseinstructionsareaddressedtoallpersonsinstalling,operatingormaintainingtheseries51BGservobevel-gearunits.

YoumustnotusetheSeries51BGservobevel-gearunitsbeforehavingreadandunderstoodtheseoperatingandmaintenanceinstructions.

Pleasegivethesafetyinstructionsalsotootherpersons.

SafetynotesThefollowingsignalsymbolsandwordsareusedintheinstructionstowarnyouand/orinformyouofsomething.

warnsyouabouthighinjuryhazardswarnsyouaboutpossibleinjuryhazardswarnsyouaboutminorinjuryhazardsand/ordamagehazardsEnvironmentallyhazardous-warnsyouaboutapollutionhazardfortheenvironmentTransportwarnsyouofinjuryhazardswhentransportingandhandlingbulkyobjectsOthersignsandsymbolsbyan"instructiontoact"youareaskedtodosomethingbyahint"youareinformedofapossiblesimplificationorimprovement#Maintenance:suggestsoptimaloperationWhenoperatedinareaswithexplosionhazardtheinstructionsidentifiedbythesym-bolaretobeobserved.

ThesewerepreparedonthebasisoftheignitiondangerratingKGA114.

Thissymbolreferstothenameplate.

Thestoragesymbolindicateshowthebevel-gearunitsshouldbestored.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite425nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite4ExclusionofliabilityThemanufacturerwillnotacceptliabilityfordamagesorinjuriesresultingfromimproperuseorhandlingoftheseries51BGservobevel-gearunits.

Impropermanipulationsandotheractsnotinaccordancewiththeseinstructionsimpairthequal-ityoftheproduct.

ThiswillleadtotheexclusionofwarrantyclaimsagainstATLANTAAntrieb-ssystemeE.

SeidenspinnerGmbH&Co.

KG.

Modifications,conversionsModificationsand/orconversionsofthegearunitarenotpermissibleunlessexpresslyapprovedbyATLANTAinwriting.

ECMachineryDirectiveAsdefinedbytheECMachineryDirective98/37ECthegearunitisnotconsideredanautono-mousmachinebutacomponenttobeinstalledinmachines.

WithinthepurviewoftheECdirectivetheunitmustnotbeoperatedunlessthemachineintowhichthisproductisinstalledfulfillstherequirementsofthedirective.

TechnicalchangesATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KGreservetherighttomaketechni-calchangestoimprovetheproduct.

ProperuseTheATLANTAseries51BGservobevel-gearunitmayonlybeusedforspeedandtorqueconversioninmachinesandmechanicalequipmentunderatmosphericpressureconditions.

Itmustnotbeusedoutdoors.

Thepermissibleinputspeedandoutputtorqueaswellasthepermissibleadditionalloadsmustnotbeexceeded.

ThelayoutinstructionsintheAtlantacataloguemustbeobserved.

Themaximumtorquespermittedarelistedinourcatalogueorourwebsite:http://www.

atlantagmbh.

deThegearboxmustnotbeusedincombinationwithcombustionengines–dangerofoverheating,inadmissibleshockloading!

Thegearunitisdesignedforinputdriveviabevel-gearshaftwithATLANTAE-servospecialclutchorATLANTAspecialclutchTheinputdriveviabevel-gear(hollowoutputshaft)maybechosenonlyafterconsultingATLANTA.

Theefficiencyratingindicatedisbaseduponinputdriveviathesplinedshaft.

Thegearunitisnotself-braking.

Thegearunitmustnotbeusedoutdoorsorunderwater.

Thesurfacetemperatureofthegearboxmustnotexceed80°Cduringoperation.

WhenusedinareaswithexplosionhazardthetemperatureofBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite525nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite5thehousingmustnotexceed65°C.

Ifnecessary,measurethesurfacetemperatureandwarnorswitchoffwhenitexceeds65°C.

Thegearunitisdesignedforintermittentoperation(S3acc.

toDINEN60034-1).

Continuousoperation(S1acc.

toDINEN60034-1)isnotpermissiblewithoutthemanufac-turer'swrittenapproval.

Continuousoperationisdefinedbythedutycycle.

Ifitexceeds30%orislongerthan20minutes,itisconsideredcontinuousoperation.

Whenusedinareaswithexplosionhazardtheinstructionsidentifiedbythesymbolaretobeobserved.

ImproperuseJWhenevertheabovementionedlimitsareexceeded(especiallyhighertorqueorspeed),thisshallbeconsideredimproperusewhichisforbidden.

Itisforbiddentooperatethegearunitif:itisnotcorrectlymounted(e.

g.

fasteningofthemotor),itisnotproperlyinstalled(e.

g.

fixingscrews),thegearunitisverydirty(e.

g.

dustdeposits)thereisnosufficientlubrication.

QualifiedPersonnelSomeresidualdangerforpersonsandobjectsmayemanatefromtheseries51BGservobevel-gearunit.

Thereforeonlyskilledandtrainedpersonnelbeingawareofpossiblerisksmaycarryoutmounting,installation,start-up,service,andmaintenancework.

Thepersonnelmusthavethenecessaryqualificationfortheworktobedoneandmustbefamiliarwithmounting,installation,startingupandoperatingtheproduct.

Inadditiontheymustcarefullyread,understandandobservetheoperatinginstructionand,inparticular,thesafetyinstructions.

Thefollowingworksshouldalsobecarriedoutonlybyqualifiedpersonnel:Transport,storage,erection/installation,connection,start-up,service,maintenanceGeneralsafetyinstructionsWedonotclaimthesesafetyinstructionstobecomplete.

IncaseofquestionsorproblemspleasecontactATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KG.

Thegearunitincorporatesthelatesttechnologicaldevelopmentatthetimeofdeliveryandcanbeprincipallyregardedassafetooperate.

Impropermanipulationsmayleadtoinjuriesanddamages.

Makesurethatthegearunitisonlyinstalled,serviced,ordisassembledbyspeciallytrainedskilledpersonnel.

Foreignmatterflungaboutmaycauseseriousinjurie.

Makesurethatnoforeignmatterortoolsarenearthegearunitbeforestartingoperation.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite625nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite6Contactwithhotsurfacesmaycauseburns.

Nevertouchgearunitswhentheyhavehighoperatingtemperatures,orusesuitableprotec-tiveequipment(e.

g.

gloves).

Rotatingpartsmaycauseinjuries.

Pulling-inrisk!

Keepsufficientdistancetorotatingmachineparts.

Neverinstalloroperatedefectiveproducts.

Incaseofdamagepleasecomplainimmediately.

ShortdescriptionTheATLANTABGservobevelgearunitwasdevelopedforusewiththree-phaseACandDCservomotors.

Itfeaturesalow-clearancegearing.

Thelight-metalcasingensuresoptimalheatdissipation.

Robustbearingsandanexcellentstiffnesspermitthetransmissionofhightorquesandadditionalforces.

Thegearunitissuppliedtest-run,tightness-checkedandthusreadyforoperation.

Thegearunitisavailablewithdifferentreductionratios.

Withinonegearboxsizeanddesignallcomponents,exceptforthesetofwheels,arethesame.

Thelast2digitsoftheitemnumberstandforthenominalreductionratio.

Theexactreductionratiocanbeseenfromtheta-blebelow.

Itemno.

ActualgearreductionApplicableto51xxx0519/4=4,75allsizes51xxx0727/4=6,75allsizes51xxx0939/4=9,75allsizesThisgearunitisavailablewith2outputvariations:hollowoutputshaftforkeyconnectionshollowoutputshaftforclampedconnectionsBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite725nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite7ItemnumberTheitemnumberiscomposedasfollows:ExampleBGservobevel-gearunitBG=80mm,i=4.

75versionwithkeyorshrink-discIdentificationThegearunitisidentifiedbyanameplatecontainingthegearboxtype,thegearratio,themax.

performanceforS3operation,themax.

speedforS3operation,theassemblydate,andtheserialnumberofthegearunit.

TypeGearratioMax.

performanceforS3operation[kW]Max.

speedforS3operation[min-1]Mass[kg]Serialnumber51050055715005BG-ServoKegelrad-getriebeBG-ServoBevelgearunitBG-ServoKegelrad-getriebeBG-ServoBevelgearunitPafeder-AusführungKeywaydesignSchrumpfscheiben-AusführungShrink-discdesignBaugreBG=80Construction-sizeBaugreBG=80Construction-sizeGehuse-IdentnummerOrdercodeofhousingGehuse-IdentnummerOrdercodeofhousingbersetzungi=4,75Ratiobersetzungi=4,75RatioBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite825nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite8Aseparateoilratingplatespecifiesthetypeofoil:Whenusedinareaswithexplosionhazardthegearunitmustbeadequatelyidentifiedbyameansofanameplate.

Onlythenitmaybeusedinsuchareas:BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite925nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite9TighteningtorquesAllscrewconnectionsforwhichtighteningtorquesarespecifiedareprincipallytobetightenedandcheckedwithacalibratedtorquewrench.

Thetighteningtorquescanbetakenfromtablesinrelevantbooks.

Shouldscrewsbeemployedacc,toDIN912,youcanusethefollowingtable:Forthecountersunkholes:Whenapplyingtorquesacc.

toyourowncompanystandard,whichallowstheutilizationof90%oftheyieldpointofthescrew,asuitablewasher/bushingshouldbeused.

Hexag.

socket-headscrewsDIN912Strengthclass8.

8/aluminiumhousingM5M6M8M10M12M16TighteningtorqueinNm*)3,58,918.

84045117Tighteningtorqueinlbfin*)31781663543981035.

5Forthethreadedholes::(Effectivelengthofthreadmin.

1.

5xdnenn/bearingsurfacesteelwithmin.

pG>300N/mm2)Hexag.

socket-headscrewsDIN912Strengthclass8.

8M5M6M8M10M12M16TighteningtorqueinNm*)5,59,5234680195Tighteningtorqueinlbfin*)48842034077081725*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighteningtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusable.

Checklist-start-upBeforestartingupWhathastobecheckedCheckedDelivery:ArethesuppliesinconformitywiththeconsignmentnoteAnytransportdamageshouldbereportedimmediatelytothecarrier.

Obviousdefects/incompletenessshouldbereportedimmediatelytoATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KG.

Applicationinareaswithexplosionhazard:Arethefollowingdataonthenameplateofthegearboxes/motorsinconformitywiththepermissibleEx"applicationareaonthesite–Explosiongroup–Category–Zone–Temperatureclass–Max.

surfacetemperatureAmbienttemperature:Istheambienttemperaturerangeacc.

tothedataonthelubricanttableobservedThemax.

ambienttemperatureof40°Cmustnotbeexceededthrough-outthewholeoperatingtime.

thetemperaturemustnotfallbelowthemin.

ambienttemperatureof-10°Cthroughoutthewholeoperatingtime.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1025nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite10Ventilation:IssufficientventilationofthegearboxensuredInputandoutputdriveelements:Areallinputandoutputdriveelementstobemountedsuitableforthespecificex"protectionuseNameplateinformation:ArethedataonthegearboxnameplatenotexceededDuringstart-upWhathastobecheckedCheckedEnvironment:Itmustbeensuredthattherearenoatmospheres,oils,acids,gases,vapours,orcombustibledustsaroundwhichmayexplode!

Temperaturemeasurement:Thetemperaturemustbemeasuredafter3hoursofoperationundermax.

operatingloadconditions!

Thetemperaturemeasurementsshallbetakenintheinputareainplaceswhichareprotectedfromthecoolingaircurrent.

Itisadvis-abletomeasureinvariousplacesinordertodeterminethemaxi-mum.

Theabsolutetemperatureof80°Conthesurfaceofthegearboxmustnotbeexceededsothatthethermalstressonshaftsealsandlubricantsiskeptlow;thishasapositiveinfluenceupontheservicelife.

Start-up/operationMakesurethatthefollowingpreconditionsfortheoperationarefulfilled:Thecontrolandprotectivesystemsmustnotbeshutoff.

Thisappliesalsofortrialrunsandstart-upoperation.

Thegearunitsmustnotbeoperatedunderthefollowingambientconditions:oExplosiveatmosphere,(exceptionCEII3GT4/II3DT130°C)ooils,oacids,ogases,(exceptionCEII3GT4/II3DT130°C)ovapours,oradiation.

Dependinguponthelubricantsusedtheambienttemperatureshouldbebetween10°Cand+40°C.

Iftheambienttemperatureslieoutsidethepermissiblerange,getintocontactwithATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KG.

Thegearunitsmustnotbeoperatedunlesssufficientventilationisensuredinordertoavoidanyheatcongestion.

Whenusedinareaswithexplosionhazard,theoperatormustensurethatthesurfacetemperatureofthegearboxdoesnotexceed65°C.

;ifnecessary,controlthesurfacetemperatureofthehousing.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1125nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite11Thesurfaceofthegearboxcanreachtemperaturesofmorethan65°C.

duringoperationandcancauseburns.

Theper-soninstallingthegearunitmusttakecarethatpersonscannotbeinjuredduetohotsurfaces.

Rotatingpartscancatchpiecesofclothing,hair,andmem-bersofthebodyandcaninjurepersons.

Thepersoninstallingthegearunitmusttakecarethatpersonscannotbeinjuredbyrotatingparts.

MaintenanceAccidentalstartingofthegearunitwhilemaintenanceworkisbeingcarriedoutcanleadtoseriousaccidents.

Makesurethatnobodycanstartthegearunit,whilemaintenanceworkisbeingperformed.

Evenshortoperationofthegearunitwhilemaintenanceworkisbeingcarriedoutcancauseaccidents,ifthesafetydevicesareshutoffandinoperative.

Makesurethatallsafetydevicesaremountedandoperative.

Shaftsealingrings:Shaftsealingringssealthegapbetweenthehousingandtherotatingshafts.

Theyarewearingpartswhichhavetobereplacedwhentheyreachthepermissiblelimitofwear.

Theservicelifeofshaftsealingringsisinfluencedbyamultitudeofparameters.

Theseareamongothers.

:peripheralspeedatthesealingliptemperatureinternalpressureinthegearboxviscosityoflubricantchemicalanalysisandadditivationoflubricantsmountingsituation(lubricantsupplytothesealinglip)particlesand/ormetallicfinesinthelubricantmaterialoftheshaftsealingringexternalpollutionThismultitudeofinfluencingparametersmakeitpracticallyimpossibletopredictthepreciseser-vicelifewithoutmakingexperimentssimulatingtherespectiveapplication.

Astheservicelifeoftheshaftsealingringsissubjecttotheabovementionedfluctuations,it.

.

isabsolutelynecessarytocheckthematregularintervals.

Onlyregularcheckscanpreventunnoticedlossoflubricantinthegearbox.

Whenevertheshaftsealingisreplacedyoushouldalsochecktherunningsurfaceofthelipsofthesealontheshaft.

Ifseizuremarksarevisible,theshaftmustberepairedorreplaced.

Alterna-tivelyitispossibletoinserttheshaftsealingringinaslightlyaxiallydisplacedpositionsothatthelipofthesealrunsinapracticallynewplaceBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1225nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite12MaintenanceintervalsProvidedthatthegearunitsareusedproperlyasdescribedinthecatalogue,theseries51BGservobevel-gearunitsaredesignedandbuiltfor12,000hofoperationexceptforwearingpartssuchasthebearingsandtheshaftsealingrings.

Thefollowingmaintenanceworksshouldbeperformedfortheseries51BGservobevel-gearunits.

IntervalWhatshouldbedoneEvery2000machinehours,butatleasteverysixmonthsChecktherunningnoisetodetectpossibledefectsinthebearingsInspectthemotorflangesforleakageInspectthesealsforleakage.

Shouldanyleakagebede-tected,pleasecontactus.

After5000…8000hours,butafter3yearsatthelatestReplacetheshaftsealingringsChangingthegearoilAsufficientamountoflubricantisabsolutelynecessaryforsafeoperation.

Thelubricantensuresthatdryrunningandconsequentlyexcessivelyhighsurfacetemperatures,wear(play),orme-chanicsparkingispreventedinthemetalliccontacts.

Themaindangerisanunnoticedlossoflubricant.

Thereforethegearunitsmustberegularlycheckedforlossoflubricant.

ATLANTAEservobevel-gearunitsarefilledwithsyntheticpolyglycoloil.

Underthefollowingpreconditionsthisisalifetimelubrication:ThelayoutofthegearunitisstrictlyinaccordancewiththeguidelinesgivenintheATLANTAcatalogue(www.

atlantagmbh.

de).

Thegearunitisexclusivelyoperatedwithinthepermissiblecharacteristicandlimitvalues(www.

atlantagmbh.

de).

Theoperatorchecksthegearunitregularly(every2weeks)forlossofoil.

Thesurfacetemperaturemustnotexceedmax.

80°Cduringoperation.

Inthecaseofoperationwithmostlylowinputspeeds(peripheralspeedofthebevelgearv40°CThemostsuitablepointforcontrollingthemax.

permissiblesurfacetemperatureofthehous-ingisintheareaoftheinput-sidebevel-gearshaftbearings.

Theverticalarrangementoftheshaft(inputoroutputverticallydownward)isonlypermissiblewithanoillevelmonitorstoppingthegearunitincaseofasuddenlossofoil.

Mountingtheoutputdriveshaft(Versionwithshrink-disc)Fortheoutputdriveshaftwerecommendtoleranceh6(DINISO286).

Thematerialmusthaveaminimumyieldpointof385N/mm2.

IfyouhaveboughttheoutputdriveshaftfromATLANTAandifitisnotsuppliedalreadymounted,werecommendtoproceedasfollows:Cleantheseatofthehollowshaftandoilitslightly(donotusegrease).

Wipeoffanyexcessoilwitharag.

Slidetheshrink-discontothehollowshaft.

Donottightenthescrewsbeforehand!

Cleantheshankoftheoutputdriveshaftandoilitslightly.

Wipeoffanyexcessoilwitharag.

abutmentscrewingsurfaceBevel-gearunitlateralforcesBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1725nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite17Pushtheoutputdriveshaftintotheborerightuptothestop.

Attachtheshrink-discbyevenlytighteningthescrewsoneaftertheother(notcrosswise).

Makesurethatthetwoclampingdiscsareplaneparallel.

Severalpassesarenecessaryuntilthescrewsaretightenedtothespecifiedtorqueacc.

tothetablebelow.

OrdercodeTighteningtorque*)808403612Nm808505012Nm808606212Nm*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighten-ingtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusable.

Soilingmayimpedethetransmissionofthetorque.

Donotdisassembletheshrink-discclampingsetbeforemountingitIfthegearunitiscleanedinthesealingareawithacleansingagentapprovedbyATLANTAAntriebssystemeE.

SeidenspinnerGmbH&Co.

KGthesurfacescleanedmustbeprotectedagainagainstcorro-sion.

Theforcesoftheshrink-disccandeformthehollowshaft.

Alwaysinstallthemachineshaftbeforetighteningtheclampingscrewsoftheshrink-disc.

Slantingtheshaftsmaycausedamage.

MakesurethatthehollowshaftandthemachineshaftarealigneWhenusedinareaswithexplosionhazardimproperinstallationmayleadtoinadmissiblyhightemperatures.

Checkthetighteningtorquesandaxialfixingafter10hoursunderoper-atingconditions.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1825nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite18Mountingtheoutput-drivepinionshaftBG50(Versionwithkey)Unlesstheoutputpinionshaftcomesalreadyfullyassembled,werecommendtoproceedasfol-lows:CleantheseatofthehollowshaftandrubwithMoS2-powderorgrease(reducesfrettingcorrosion).

Insertthelockingwasherintotherecessofthehollowshaft.

.

Insertthelockingwasherfromtheoppositesideuptothestopinsidethehollowshaft.

.

Connectthemountingplateandtheoutputshaftbymeansofthescrew.

Securethescrewusingsuitableadhesive(e.

g.

Loctite243).

*)Drylubricant:Improvestheslidingpropertiesofmachinepartsandreducesfrictionandwearwithinawidetemeperaturerange;minimumfrictionwithmaximumloadcapacit.

GearboxwithoutoutputshaftInsertpinionshaftMountretainingdisk/lockscrewandtightenTheretainingring,washerandscrewsuppliedwiththedriveshaftservefortheaxialfixationoftheinputdrivingshaft.

ForgearboxessizeBG50anadditionalwasher25109001isrequiredwhichreplacesthetwoitemsretainingring+lockingwashersuppliedtogetherwiththedrivingshaft.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite1925nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite19Mountingtheoutput-drivepinionshaftBG63andBG80(Versionwithkey)Unlesstheoutputpinionshaftcomesalreadyfullyassembled,werecommendtoproceedasfol-lows:CleantheseatofthehollowshaftandrubwithMoS2-powderorgrease(reducesfrettingcorrosion).

Inserttheretainingringintotherecessofthehollowshaft.

Pushintheoutputshaftrightuptothestop.

Insertthelockingwasherfromtheoppositesideuptothestopinsidethehollowshaft.

Connectthemountingplateandtheoutputshaftbymeansofthescrew.

Securethescrewusingsuitableadhesive(e.

g.

Loctite243)*)Drylubricant:Improvestheslidingpropertiesofmachinepartsandreducesfrictionandwearwithinawidetemeperaturerange;minimumfrictionwithmaximumloadcapacit.

GearboxwithoutoutputshaftInsertSpringInsertpinionshaftMountretainingdisk/lockscrewandtightenHexagonsockethead-screwsDIN912strengthrating8.

8/lockingwasherM5M8M12M16TighteningtorqueinNm5.

52380195Tighteningtorqueinlbfin48.

5203.

57081726*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighteningtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusableSlantingtheshaftsmaycausedamage.

Makesurethatthehollowshaftandthemachineshaftarealigned.

Mountthemachineshaftinthehollowshaftwithoutusingforce.

Nevertrytomountitbymeansofknockingitin.

Useonlysuitabletoolsanddevices.

Whenusedinareaswithexplosionhazard,improperinstallationmayleadtoinadmissiblyhightemperatures(seeignitiondangerratingacc.

toKGA114).

Checkthetighteningtorquesandtheaxialfixingafter10hworkunderoperatingconditions.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2025nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite20655XXXX654XXXXMountingtheclutchonthemotorshaftATLANTAEservospecialclutch655XXXXorATLANTAspecialclutch654XXXXTheclutchissuppliedpre-assembled.

VBeforemountingtheclutchonthemotorshaftcleanallcontactsur-facesandcoatthemwithathinoilfilm(nogrease).

AnyexcessoilshouldbewipedoffwitharagRubtheDIN5480profileoftheclutchwithMoS2powderorgrease(reducesfrettingcorrosion)Ifthemotorshafthasakey,itshouldberemoved.

Slidetheclutchontothemotorshaftasfarasspecifiedinthecata-logueasX1"(655XXXX)and/orrightuptothestop(654XXXX/shoulderorretainingring).

Inthecaseofclutch655XXXXintermediatesleevesmaybeusedinordertoreachthemotor-shaftdiameter.

Insuchacasetheslotintheintermediatesleevemustbealignedwiththeslotintheclutchbody.

Slightlytightentheclampingscrews.

Tightenscrewsuniformlybyturningthemalternately(crosswisewith654XXXX).

.

Checkclutchfortruerunningatthereferencediameter(fr<0.

04mm).

Severalpassesarenecessaryuntilthescrewsaretightenedtothetighteningtorquespeci-fiedinthetablebelow.

Makesurethatthewidthofthegapbetweenclutchandpressuresurfaceremainsuniform.

Checkatreferencediameterfortruerunning.

OrdercodeofclutchTighteningtorque*)OrdercodeofclutchTighteningtorque*)6551xxx7Nm62lbfin6543xxx7Nm62lbfin6553xxx7Nm62lbfin6544xxx10Nm88,5lbfin6554xxx10Nm88,5lbfin6546xxx10Nm88,5lbfin6555xxx25Nm221lbfin6547xxx25Nm221lbfin*)Useonlycalibratedtorquewrenches!

Ifthetighteningtorqueistoolow,therequiredtorquewillnotbetransmitted.

Ifthetighten-ingtorqueistoohigh,thescrewswillbeoverstrainedandbecomeunusable.

Whenusedinareaswithexplosionhazard,improperinstallationmayleadtoinadmissiblyhightemperatures(seeignitiondangerratingacc.

toKGA114).

Checkthetighteningtorquesandtheaxialfixingafter10hrsworkunderoperatingconditions.

Whenusedinareaswithexplosionhazard,usecorrosion-protectedscrews.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2125nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite21MountingthemotorCleanflangesurfaceandcenteringshoulderonmotorandgearbox.

Slidethemotorwithcouplingmountedontotheteethoftheinputdriveshaftandintothegearcenteringpiecesothattheplanesurfacestouch.

Ifnecessary,rotatethemotoraroundthemotoraxleuntiltheclutchandtheinputshaftteethmesh.

.

Themotormustslideoneasily.

Theremustnotbeanygapbetweenthemotorandthegearboxflange.

Mountingmotorshavinglongershaftsthanpermissiblefortherespectivegearunitleadstotensionswhichdamagethemotorandthegearunit.

Checktheinterferingedgesbymeasuringoutorbycheckingthedimensionaccordingtoourcataloguedataandthemotormanufacturer'sdata.

Screwmotorandgearboxtogether.

Hexagonnutsorscrewsaretobetightenedtothespeci-fiedtorqueandsecured.

Thecorrecttighteningtorquecanbeseenfromtherespectiveta-bles.

Inthiscontextitisparticularlyimportanttopayspecialattentiontothestrengthclassofthescrewandthematerialofthesupportingsurfaces.

Themotorcanbemountedoptimallycenteredbypositioningthegearboxinsuchawaythatthebevel-gearshaftisstandingupvertically.

Usescrewswithaneffectivelengthofatleast1.

6xthreaddiameter.

Whenusedinareaswithexplosionhazard,usecorrosion-protectedscrewsMounttheclutchonthemotorshaftandfastenasdescribedCleanmotorandclutchsurfacesBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2225nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite22Screwmotortogearbox,Usepropertighteningtorqueforscrews*)Drylubricant:Improvestheslidingpropertiesofmachinepartsandreducesfrictionandwearwithinawidetemeperaturerange;minimumfrictionwithmaximumloadcapacity.

CleanscrewingsurfacesofmotorandgearboxandrubwithMoS2*)powderorgreaseBWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2325nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite23TransportandhandlingTherearenospecialholesorthreadsprovidedfortransportingandhandlingthegearunit.

Thereare,however,numerousfixingthreadsavailableinthegearhousingpermittingtoscrewineye-boltssothatitispossibletohandlethegearboxsafely.

Observeallsafetyregulationsinconnectionwithtransportandhandlingusingliftinggear.

Makesurethattheloadishandledandsetdownslowlyandcarefully.

GearboxsizeWeightwithoutattachmentsBG50≈3,2kgBG63≈6kgBG80≈8kgStorageIfthegearunitisnotinstalledimmediatelyafteritsdelivery,thefollowingmeasuresaretobetaken:Storethegearunitwithhorizontalhollowoutputshaftandhorizontalinputdriveshaft(wormshaft)ontopinsuchawaythat-exceptforthesupportingsurface-itcannotcomeintocontactwithanyotherobjectsProtectthegearunitsfromdetrimentalenvironmentalinfluences(highairhumidity,saltyair,aggressivegases;UVlight,electricwelding;dust;dirt,shocks;temperaturefluctuations;[0°Cto+30°C],etc.

).

Connectingparts,e.

g.

clutchoroutputshaft,aretobestoredseparately.

Protectthesteelpartsagainstcorrosion.

Aslogisticsprincipleforstore-keepingwerecommendthefirstin–firstout"principle.

Occasionallyturningtheinputshaftofthegearunitwillfacilitatethestart-upThemax.

storagetimeundersuchconditionsis2years.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2425nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite24Failurelist(Troubleshooting)Youshouldtakeremedialmeasuresatonce,ifyougetawareofoilloss,increasedoperatingnoises,orincreasedoperatingtemperatures.

Anydisturbancesoccurringduringthewarrantyperiodrequiringtherepairofthegearunit,mayonlyberemediedbyATLANTA.

Werecommendtoaskforourassistancealsoaftertheexpirationofthewarrantyperiod.

Alwaysshutdownthegearboxduringtheeliminationofdisturbances.

Securethedrivingunitagainstinadvertantstarting.

Postanoticeattheswitchingposition.

ProblemPossiblecauseRemedyLayouttoweak;Speed/torquetoohighCheckthetechnicaldataMotorheatsupthegearunitChecktheattachmentcircuit,replacethemotor,orprovideaninsulationbetweenmotorandgearunitAmbienttemperaturetoohighEnsureadequatecoolingIncreasedoper-atingtempera-tureDutycycletoolongVerifythelayoutDefectivebearingDefectivetoothsystemPleasecontactusThefixingofthegearunithasloosened.

Tightenscrews/nutswiththespecifiedtight-eningtorque.

Replacedefectivescrews/nuts.

Increasedopera-tingnoiseAdjustmentofcontroller.

Checktheservo-motorparametersLeakageGetintocontactwithus.

LossofoilApparentleakageAtemporaryleakageduetomuchgreasebetweensealinglipandprotectivelip.

Thesurplusgreasecanpenetrateoutsideasanapparentleakage.

BWK115OperationandMaintenanceIn-structions4100-001-12.

93AbteilungTBSeite2525nd.

IndexNameWessolowski18.

09.

2008Datum51erBG-Servo-Bevel-GearUnitsTranslationfromtheGermanoriginalfreigegeben00000397976117233565.

DOCSeite25DisposalPleaseobservethenationalregulations!

Ifrequired,disposeoftheindividualcomponentsseparatelydependingontheirnatureandanyexistingspecificnationalregulations,e.

gas:Steelscrapogearwheelsoshafts(hollowshafts)oantifrictionbearingsocastironpartsoclutchesAluminiumscrapohousingelementsoadaptorelementsBronzescrapobevelgear(separatedfromhollowshaft)CollectwasteoilanddisposeofasdirectedATLANTAdoesnotacceptliabilityforanydamagetothetransmissionoranyconsequentialdamage,iftheseinstructionsarenotobserved.

- latestwisediskcleaner相关文档

- aspectwisediskcleaner

- avoidwisediskcleaner

- outcomewisediskcleaner

- device44wisediskcleaner

- 0.5wisediskcleaner

- Supportingwisediskcleaner

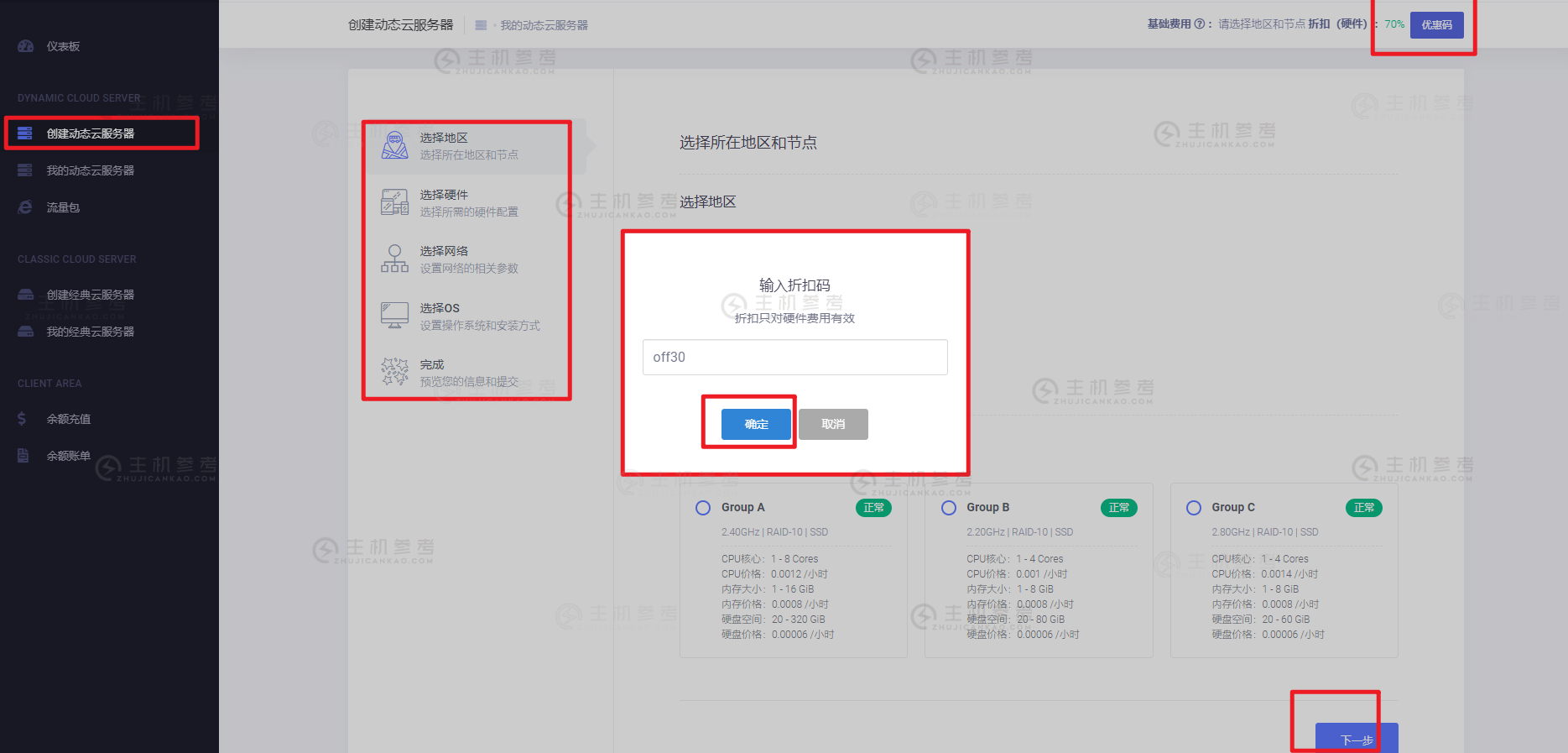

HostMem,最新优惠促销,全场75折优惠,大硬盘VPS特价优惠,美国洛杉矶QuadraNet机房,KVM虚拟架构,KVM虚拟架构,2核2G内存240GB SSD,100Mbps带宽,27美元/年

HostMem近日发布了最新的优惠消息,全场云服务器产品一律75折优惠,美国洛杉矶QuadraNet机房,基于KVM虚拟架构,2核心2G内存240G SSD固态硬盘100Mbps带宽4TB流量,27美元/年,线路方面电信CN2 GT,联通CU移动CM,有需要美国大硬盘VPS云服务器的朋友可以关注一下。HostMem怎么样?HostMem服务器好不好?HostMem值不值得购买?HostMem是一家...

BeerVM1GB内存/VDSps端口1GB,350元/月

beervm是一家国人商家,主要提供国内KVM VPS,有河南移动、广州移动等。现在预售湖南长沙联通vds,性价比高。湖南长沙vps(长沙vds),1GB内存/7GB SSD空间/10TB流量/1Gbps端口/独立IP/KVM,350元/月,有需要的可以关注一下。Beervm长沙联通vps套餐:长沙联通1G青春版(预售)长沙联通3G标准版(预售)长沙联通3G(预售)vCPU:1vCPU:2vCPU...

Gcore(75折)迈阿密E5-2623v4 CPU独立服务器

部落分享过多次G-core(gcorelabs)的产品及评测信息,以VPS主机为主,距离上一次分享商家的独立服务器还在2年多前,本月初商家针对迈阿密机房限定E5-2623v4 CPU的独立服务器推出75折优惠码,活动将在9月30日到期,这里再分享下。G-core(gcorelabs)是一家总部位于卢森堡的国外主机商,主要提供基于KVM架构的VPS主机和独立服务器租用等,数据中心包括俄罗斯、美国、日...

wisediskcleaner为你推荐

-

京沪高铁上市首秀哪些企业建设京沪高铁?www.7160.com电影网站有那些陈嘉垣马德钟狼吻案事件是怎么回事789se.com莫非现在的789mmm珍的com不管了103838.com39052.com这电影网支持网页观看吗?www.bbb551.com广州欢乐在线551要收费吗?www.kaspersky.com.cn卡巴斯基中国总部设立在?yinrentangweichentang产品功效好不好?www.toutoulu.com外链方案到底应该怎么弄呢月风随笔关于春夏秋冬的散文