水分翻译Effect of Tempering Conditions on Milling Performance概要1

Effe ct of Te mpe ring Conditions on Milling Pe rformance and Flour Functionality

润麦对于制粉性能和面粉质量的影响

ABS TRACT Tempering conditions of wheat grain change the quality of the flour, yet mostexperimental milling systems use a standard tempering without optimization. The effect oftempering condition on milling performance and flour functionality for soft red winter (SRW)wheat grain was tested by measuring flour yield, ash, polyphone oxidase (PPO), andsolvent retention capacity(SRC) in grain samp les from three SRW cultivars (Roane,Cyrus, andSevern).Tempering was conducted with a full factorial design of initial wheat moisture, temperedwheat moisture, tempering temperature, and tempering time at two levels. Tempered wheatmoisture had the largest effect on milling performance and flour functionality. Flour yield wasmore reduced for all samples tempered at 15%moisture than for samples tempered to 12%moisture.Flour quality of the 15%tempered sample was better than the 12%tempered samplesdue to less bran contamination as measured by flour ash and PPO. Increasing the temperingmoisture increased flour sucrose SRC and lactic acid SRC but reduced sodium carbonate SRC forsamples.Changing tempered wheat moisture changed flour yield and quality much more than didchanging the length of time for tempering, the temperature at wheat is tempered,or differences inthe initial moisture of the wheat before tempering.The last three effects could be used to improveflour yield in both the 12 and 15%tempered wheat treatment but the detrimental effects of thesetreatments on flour quality were minimal when combined with the 15%tempered wheat moisturetr eatment.

润麦对于制粉性能和面粉质量的影响

摘要谷物的润麦可以改变面粉质量迄今为止大部分的实验制粉系统采用标准的润麦系统并非最优的。润麦对于软红麦SRW的影响通过对于三种软红冬麦SRW品种的样品检测其面粉产量灰分多酚氧化酶P P O和溶剂保持能力S RC可知。润麦采用的是关于原麦水分润麦后小麦水分润麦温度润麦时间的完整的析因设计。润麦湿度对于制粉性能和面粉质量影响最大。润麦15%湿度相较于润麦湿度12%的面粉出粉率大大下降。然而由于较少麸皮污染通过灰分和多酚氧化酶比较可知15%润麦湿度的面粉质量比12%润麦湿度的面粉高。润麦湿度越大面粉蔗糖和乳酸的溶剂滞留越大碳酸钠的溶剂滞留越小。相比于润麦时间和润麦温度润麦水分的改变对于面粉出粉率和质量的影响较大或者可以说主要差别在润麦前小麦的水分。这三种因素可以用来改进12%和15%润麦湿度的出粉率只是这些改变面粉质量的方法所衍生的损害较小的。

Tempering is the process of adding water to wheat before milling to toughen the bran andmellow the endosperm of the kernel and thus improve the efficiency of flour extraction.Numerousresearchers have reported studies on water uptake,movement, and diffusion during tempering(Stenvert and Kings wood 1976, 1977;Songetal 1998;Kang and Delwiche 1999,2000;Delwiche

2000).Tempering temperature,moisture, and time affect rate of moisture up take to wheat, andwheat cultivar, initial wheat water content, vcand kernel size and temperature also influence thatrate (Posnerand Hibbs 1997).Although the rate of water penetration into wheat during temperingvaried for different cultivars, the mode of movement was essentially the same (Stenvert andKingswood1976).The rate also was influenced by endosperm structure and protein content anddistribution (Stenvert and Kingswood 1977). Tempering toughens pericarp, and fewer smallpericarp particles are formed during milling.However, as tempering moisture with in the kernelincreased, flour extraction rate decreased.Therefore, the tempering procedure should balanc e the

level of flour extraction and acceptable level of bran in flour (Hook etal 1982a,b,c).

润麦就是研磨前向小麦加水让麸皮变坚韧润化胚乳提高面粉出粉率。之前报道了很多有关润麦时的吸水性运动和扩散的研究(Stenvert and Kings wood 1976, 1977; Songetal 1998;Kang and Delwiche 1999,2000;Delwiche 2000)。润麦温度水分时间影响小麦湿度小麦品种原小麦水分含量麦粒大小和温度同样影响小麦湿度(Posnerand Hibbs 1997)。虽然润麦时不同小麦的透水率有所不同运动模式时基本相同的(Stenvert and Kingswood1976)。还有胚乳结构和蛋白质含量和分布同样影响着润麦(Stenvert and Kingswood 1977)。润麦让麦皮更坚韧制粉时很少的小粒麦皮时成形额。然而随着润麦湿度增加出粉率也增加。因此润麦过程应该平衡出粉率和面粉中麸皮的等级(Hook etal 1982a,b,c)。

Most tempering studies have focused on tempering mechanism and milling yield but notflour quality.Few reports link tempering effects to flour qualities such as ash content, farinograph,and extensigraph quality(Butcher and Stenvert 1973; Ibanoglu 2001).Ash content of flour hasbeen used as an indicator for bran contamination but it is the measurement of inorganiccompounds.Ash does not directly measure arabinoxylans,which are major functional flourcomponents related to mixing and baking,and elevated by bran layers.Fuerst et al (2006)reportedthat most polyphenol oxidase (PPO) is located in bran; determination of PPO activity can beanother valid indicator to measure bran contamination. For evaluating flour functionality, thesolvent retention capacity(SRC) test is increasingly used to test the functional contribution ofeach flour component such as glutenins, damaged starch, and arabinoxylans (Guttierietal 2001,2002;Bettge et al2002;Guttieri and Souza 2003;Ram and Singh 2004;Ram et al2005;Roccia etal 2006;Xiao et al 2006).Water SRC is related towater absorption capacity for all flourcomponents, lactic acid SRC to general gluten strength, sodium carbonate SRC to dam-agedstarch,and sucrose SRC to arabinoxylans.

大部分润麦方面的研究都着重于润麦水分和出粉率忽视面粉质量。很少有报道提及润麦对于面粉质量的影响例如灰分粉质仪质量和拉伸质量(Butcher and Stenvert 1973;Ibanoglu 2001)。灰分含量之前被作为麸皮含量的一个指标但现在是关于无机化合物的测量。灰分并非直接测量阿糖基木聚糖阿糖基木聚糖是有关混合烘焙的主要面粉成分。Fuerst et al于2006年报道过主要的多酚氧化酶PPO存在于麸皮中多酚氧化酶活性的测定可以作为麸皮污染的又一个有效的指标。溶剂滞留越来越被用于测试面粉成分例如谷蛋白破损淀粉和阿糖基木聚糖(Guttierietal 2001, 2002;Bettgeet al2002;Guttieri and Souza

2003Ram and Singh 2004;Ram et al2005;Roccia et al 2006;Xiao et al 2006)。水分溶剂滞留和面粉成分的吸水率有关乳酸溶剂滞留和面筋强度有关碳酸钠溶剂滞留与破损淀粉有关蔗糖溶剂滞留与阿糖基木聚糖有关。

Despite several studies of tempering effects on flour functional-ity in hard wheats, few recentstudies have reported tempering on soft wheat flour functionality.We tested initial wheat moisture(initial moisture of the grain), tempered wheat moisture (moisture level to which the grain wastempered), tempering temperature(temperature at which the tempering occurred), and temperingtime (length of time for which the tempering occurred) in a factorial experimental design.Ourgoal was to seek treatment combinations that could elevate flour extraction, flour quality, or bothas determined by flour yield on an experimental mill, softness equivalent (for predicting breakflour yield), flour ash,PPO,and SRC testing.

尽管润麦对于硬麦的面粉质量的影响的研究有一些很少研究软麦方面。我们在因子测试里

检测了原始小麦水分润麦后小麦水分润麦温度和润麦时间。我们意在找到一个组合可以提高出粉率和面粉质量或者这两者可以通过面粉产量判断柔软等效灰分多酚氧化酶和溶剂滞留测试。

MATERIALS AND METHODS

Mate rials

Based on historical milling quality data at Soft Wheat Quality Laboratory, three soft redwinter (SRW)wheat cultivars (good milling Severn, average milling Cyrus, and poor millingRoane)were selected for the study. Samples were received from Purdue University,where theywere grown together at West Lafayette, IN in 2004.All chemic als were reagent grade.

材料和方法

材料

根据软麦品质研究室的数据三种软红冬麦ood milling Severn, average milling Cyrus,and poor milling Roane被选作研究样本。样品由普渡大学提供这些样品长在普渡大学西拉法叶校区所有化学品均为试剂等级。

Tempering and Milling of Wheat For an experimental design, initial wheat moisture,tempered wheat moisture, tempering temperature,and tempering time were chosen as factors,andtwo levels were selected for each factor: initial wheat moisture,≈7 and 10.2%; tempered wheatmoisture, 12 and 15%; tempering temperature,25 and 45°C;and tempering time, 3 and 24 hr.Foreach wheat cultivar, tempering experiments were conducted by a full factorial design(24= 16runs) in random order.The wheat samples with 7%initial wheat moisture content were preparedby drying cleaned wheat berries (10.2%moisture content)at 43°C for approximately five days toreach the targeted weight.Cleaned wheat sample (200 g)weighed in a glass jar was mixed withtempering water and tempered at each tempering condition.The amount of tempering water wascalculated according to initial wheat moisture (7or10.2%) and tempered wheat moisture (12 or15%) contents.The tempered wheat sample was milled with an advanced Quadrumat Jr.mill(Brabender Instruments,South Hackensack,NJ)which consisted of two Quadrumat Jr.mill units.The first was a regular mill for break and the second was a modified mill for reduction.Tylerstainless steel bolting cloth 40 mesh(470µm)and 94 mesh(180µm)was used for sieving of themill stream for the break mill, and 84 mesh(213 µm)was used for sieving of the further reducedstream of OV 94 mesh(<40 mesh and>94 mesh fraction)using the reduction mill. The flourstreams<94 mesh from the first break mill and<84 mesh from the second reduction mill wereblended well and used for further analysis.We anticipated that the particle size was relativelylarger for the blended flour due to using a coarser sieving screen than the flour milled withlong-flow experimental mill (Miag Multomat and Allis Chalmers) or commercial mill.The flouryield and softness equivalent (SE)were explained by Finney and Andrews (1986) and calculatedas Yield= 100× [1–(Ov40 mesh/wheat wt)] and SE=100× [1–Ov 94 mesh/(wheat wt–Ov 40mesh)], respectively, in this study.

对于润麦实验设计 以原始小麦水分润麦后小麦水分润麦温度和润麦时间为要素每个要素选定为两种层次原始小麦水分7%和10.2%润麦后小麦水分12%和15% 润麦温度25°C和45°C 润麦时间3小时和24小时。对于每种小麦润麦实验进行了一个完整的随机因子设计。 7%原始小麦水分的小麦被作为干洗小麦10.2%水分在43°C的

温度下润麦大概5天以达到目标重量。干净小麦每200克放在一个玻璃罐里加水润麦。加水量时根据原始小麦水分7%或者10.2%和润麦后小麦水分(12%或者15%)计算出的。润麦后的样品采用先进的工艺研磨包含两种Quadrumat Jr.研磨mill units。第一种是常规的研磨破碎第二种是改良的研磨筛分。常规的研磨破碎采用的是tyler不锈钢bo lt ing筛绢40筛孔(470µm)和94筛孔 180µm。改良的研磨筛分采用的是84筛孔(213µm) >94筛孔

<40 目 and>94 目。第一种研磨的<94 目的面粉和第二种筛分的<84 目的面粉混合且被用于进一步的研究分析。对于混合的面粉我们预计颗粒大小相对来说较大。原因是使用较粗的筛网。面粉产量和柔软度由Finney和Andrew s 1986解释计算量=100×[1–(>40 目/小麦wt)] SE=100× [1–>94 目/(小麦wt–>40 目)] 。

Proximate Analyses and Total PPO Assay Moisture content was measured with ApprovedMethod44-16and ash content was determined with Approved Method 08-01 (AACC International

2000). Total PPO assay of milled flour samples was based on the modification of ApprovedMethod 22-85 and the method used by Jukantietal (2003).Flour (150 mg)was weighed into a2mL microcentrifuge tube, and 1.5mL of 10mML-DOPA in 50mMMOPS buffer with50mMSDSwas dispensed into the tube.The tube containing flour slurry was placed on a rotating shakerimmediately, rotated for 30min, and centrifuged at5,000×g for10 minusing an Eppendorfcentrifuge.The supernatant was measured its absorbance at 475 nm at 1 hrafter adding LDOPAsolution, and the PPO results were expressed asA475 hr1g flour–1.The PPO assay was done induplicate.

样品解析和总多酚氧化酶含量水分是通过被认可的方法44-16测量的灰分由被认可的方法08-01测定国际谷物化学家协会2000。研磨的面粉样品中总多酚氧化酶含量是基于修订的被认可的方法22-85和Jukantieta l使用的方法2003。称量150克面粉放入一个2毫升的微量离心管 50mMMOP S中的1.5毫升的10mML-DOPA和50mMSDS放入试管。把有面粉液的试管放在旋转的振动器上转动30分钟 5000×g离心10分钟 上层清液加上LDOPA溶液后的吸收率是1小时475nm多酚氧化酶的结果是A475 hr1 g粉–1多酚氧化酶含量测定一式两份。

SRC Test

The standard SRC solvents (deionized water, 5%sodium carbonate, 5%lactic acid, and 50%sucrose) were prepared according to the Approved Method 56-11 (AACC International

2000).Flour (5 g)was suspended in 25 g of each solvent for 20 min with intermittent hand shakingat 5, 10, 15,and 20 min.Flour suspension was centrifuged at 1,000×g for 15 min and drained for10min. The pellet was weighed and SRC value was calculated. The SRC assay was done induplicate.

根据方法56-11 国际谷物化学家协会2000制备标准的S RC溶剂去离子水 5碳酸钠5的乳酸和50的蔗糖。5克面粉悬浮在每种溶剂25克20分钟间歇性地在5,10,15和20分钟时晃动。面粉悬浮液在1000×g下离心15分钟沥干10分钟后称量沉淀计算S RC值。 S RC测定一式两份。

Statistical Analys is Statistical software (JMP v.7.0; SAS Institute,Cary,NC)was used foranalyzing the results of the factorial design, and the significant factors to each response wereanalyzed with analysis of variance using SAS software. The model’s fixed effects were initial

wheat moisture, tempered wheat moisture, tempering temperature,and tempering time.Cultivarswere assumed to be random effects in this model.The three cultivars were not selected for specificmilling and baking quality effects but, rather, torepresent a sample of the cultivars milled in theeastern United States.As random effects, interactions between cultivars and the fixed effects of thestudy were not analyzed but,rather,pooled as an error estimate for the fixed effects of the model.For factorial analysis, estimates of main effects and interaction effects were evaluated andsignificant factors were decided by half-normal plot.

利用统计分析软件(JMP v.7.0;SAS Institute,Cary,NC)分析不同润麦水分的结果重要的因素通过方差分析借助于SAS软件进行分析。 固定的影响因素有原始小麦水分润麦后小麦水分润麦温度和润麦时间。小麦品种被认作是随机效应。这三种样品并不是为了特定的制粉烘焙质量所挑选的而是为了展现美国东部的小麦品种。关于随机效应这次并没有分析有关小麦品种和固定影响因素间的相互作用却是被看做是固定因素的误差估计。有关因子分析对主要效应和相互作用进行了评估重要的因素由一半正常的情节决定。

TABLEI

Analys is of Variance Mean Squares by General Linear Model Procedure for Milling Performanceand Flour Functionality Responses with Various Tempering Conditions

列表一

通过一般线性模型过程的各种不同润麦条件下的制粉性能和面粉质量反应的方差分析

a SE, softness equivalent;PPO,polyphenol oxidase;and SRC, solvent retention capacity.b *, **,and***,mean square term significant at P<0.05,0.01,and 0.001%,respectively.c WM, initial wheat moisture;TM, tempered wheat moisture;TP, tempering temperature; andTT, tempering time.a SE柔软等效 PPO多酚氧化酶 SRC溶液滞留量b *, **,和***指均方差P<0.05,0.01,0.001%。c WM原始小麦水分 TM润麦后小麦水分 TP润麦温度 TT润麦时间

TABLEII

Tempering Treatment Averages for Milling Performanc e and Flour Functionality

列表二

制粉性能和面粉质量的润麦处理的平均值

a SE, softness equivalent;PPO,polyphenol oxidase;and SRC, solvent retention capacity.b WM, initial wheat moisture;TM, tempered wheat moisture;TP, tempering temperature; and TT,tempering time.c Expressed asΔA475/hr/150 mg.a SE柔软等效 PPO多酚氧化酶 SRC溶液滞留量b WM原始小麦水分 TM润麦后小麦水分 TP润麦温度 TT润麦时间c ΔA475/小时/150 mg.

RESULTS AND DISCUSSION

Our primary interest was in single-factor and two-way interactions. In this study, two-wayinteractions were often signific ant (TableI).However, the three and four-way interactions werenonsignificant for all response variables except flour ash.With flour ash, the significant Fvalues weremuch smaller than the Fvalues for the two-way interaction treatment effects on flour ash(data notshown).Fitting all three and four-way interactions resulted in an R2 value for the model of 97%.Reducing the model for treatment effects on flour ash to main effects and two-way interactionsonly reduced the R2 to 95%.Therefore,we conclude that the reduced model for flour ash capturesthe most important model effects.

结果与讨论

我们主要对于单因素和双向交互作用感兴趣。在这次研究中双向交互作用一直很重要见列表一然而对于除了灰分之外的所有的反应变数来说三向 四向交互作用不那么重要。对于灰分来说 F值相比于双向交互作用处理效应的F值小(数据未列出)。采用所有的三向 四向交互作用可以得到这个样式的97%的R2值。减少这个样式下的对灰分的处理效果双向交互作用的R2值减小到95%。因此我们可以得出结论就是灰分的简化样式可以获得更重要的效应。

The tempered wheat moisture produced the largest differences in milling performance andflour functionality among the four tempering factors.Within the milling industry, the optimummilling moisture is 14–17%and the level of moisture added to the grain depends on wheat class,with hard wheat sconditioned to15.5–17%moisture content and soft wheat’s to 14–15.5%moisture content (Posner and Hibbs 1997).Expanding the range in tempering conditions cited byPosner and Hibbs (1997)produced significant differences in flour yield, ash, and PPO(Table I).The treatment effects on flour yield were greatest with tempered wheat moisture, followed bytempering time, tempering temperature, then initial wheat moisture (Table II).Generally, themagnitude of treatment effects on flour yield was reflected in the effect of the treatments on flourquality,with tempered wheat moisture having the greatest effect on the individual measures ofwheat quality.The exception was water SRC,where initial wheat moisture treatments producedgreater F values than tempered wheat moisture (TableI).The15%tempered wheat moisture, 7%

initial wheat moisture, 45°C tempering temperature, and 3-hr tempering time resulted in morereduced flour yield, reduced ash content, and reduced PPO activity than in each correspondingopposite condition(Table II).

在面粉润麦水分影响因素中润麦后小麦水分对制粉性能和面粉质量造成的差别最为显著。在制粉行业中最优的制粉水分为14-17%加水的量取决于小麦的品种硬麦加水15.5-17%软麦加水14-15.5%Posner and Hibbs 1997。根据Posner和Hibbs 1997扩大润麦的范围对面粉出粉率灰分和多酚氧化酶P PO产生的影响较显著参看列表一。润麦后小麦水分对对面粉出粉率的效果最大其次是润麦时间润麦温度最后是原始小麦水分参看列表二。一般来说对出粉率的影响效应通过面粉质量反映出来润麦后小麦水分对小麦质量有很大影响。水分滞留率是一个例外原始小麦水分的F值比润麦后小麦水分的F值大参看列表一。润麦后小麦水分15%原始小麦水分7%润麦温度45°C润麦时间3小时这样的条件下与各自相反的条件相比面粉出粉率大大降低灰分降低多酚氧化酶活性降低参看列表二。

Among interactions, tempered wheat moisture and tempering time affected most responses,such as SE, flour ash,PPO,water SRC, lactic acid SRC, and sodium carbonate SRC(Table I).Sucrose SRC was not influenced by any interactions between tempering conditions,whereas flourash and sodium carbonate SRC were influenced by most tempering interactions.The treatmentaverage values by interactions are presented in Table III.At 12%tempered wheat moisture, 10.2%initial moisture resulted in greater flour ash,water SRC, and sodium carbonate SRC than 7%initial moisture.Also,with 3 hr of tempering time, 10.2%initial wheat moisture resulted in greaterflour yield and ash and less SE than 7%initial wheat moisture. In addition, 12%tempered wheatmoisture generated more damaged starch than 15%tempered wheat moisture, as measured bysodium carbonate SRC.With 24 hr of tempering time, 25°C tempering temperature gave greaterflour yield, ash, and sodium carbonate SRC and more reduced SE than 45°C temperingtemperature.Rather than identifying large cros sover effects of treatment interactions, statistic alsignificance of the interaction effects derive from the accuracy of measurements detecting smallchanges in range for a single factor affected by the second factor.

不同条件下润麦后小麦水分和润麦时间的影响因素最多例如 SE,灰分多酚氧化酶水分滞留率乳酸滞留率碳酸钠滞留率参看列表一。蔗糖滞留率不受任何润麦条件的相互影响但是灰分和碳酸钠滞留率受大部分润麦水分相互作用的影响。相互作用的平均值请参看列表三。润麦后小麦水分12%原始小麦水分10.2%的条件与7%的原始小麦水分相比 10.2%的会产生更高的灰分水分滞留率和碳酸钠滞留率。 同样的 3小时的润麦时间 10.2%的原始小麦水分与7%的原始小麦水分相比 10.2%的会产生更大的出粉率和灰分和较小的SE。与15%的润麦后小麦水分相比 12%的润麦后小麦水分通过碳酸钠滞留率的测试会产生更多的破损淀粉。 24小时润麦时间 25°C润麦温度与45°C相比 25°C润麦温度会产生更大出粉率灰分和碳酸钠滞留率和较小的SE。不用研究相互作用的大的交叉影响测量精度衍生出的相互作用的统计数据受第二因素的影响对单个因素的改变较小。

TABLEIII

Tempering Treatment Averages by Interactions for Milling Performanc e and Flour Functionality列表三

润麦对于制粉性能和面粉质量的相互作用平均值

a SE, softness equivalent,PPO,polyphenol oxidase,and SRC, solvent retention capacity.b WM, initial wheat moisture;TM, tempered wheat moisture;TP, tempering temperature;and TT,tempering time.

C Expressed asΔA475/hr/150 mg.

Effect of Tempered Wheat Moisture on Milling Performance

润麦水分对制粉性能的影响

The flour yields with reduced tempered wheat moisture were greater than those withincreased tempering moisture treatment,which is consistent with reports by Hook et al (1982a,b,c).The effect of the tempering moisture carried through to the flour moisture contents,where12%tempering moisture treatment had flour moistures of 11.7–12.0%and the 15%temperingmoisture treatment ad 13.7–14.3%(Fig. 1). Softness equivalent was greater for the flour sampleswith the 15%tempering moisture than those with the 12%tempering moisture within samecultivar,which indicated that the kernels were moistened, softened,and then easy to mill (Fig. 1A).Gaines et al (2000) reported that SE is closely related to break flour yield obtained from AllisChalmers milling.

较小的润麦后小麦水分的出粉率比较高的润麦水分的出粉率高这一点与Hook et al的报告一致1982a, b,c。润麦水分对面粉水分有影响 12%的润麦水分产生11.7-12.0%的面粉水分 15%的润麦水分产生13.7-14.3%的面粉水分图表1。 同样的小麦品种与12%的润麦水分相比 15%的润麦水分下的面粉的柔软性较高这表明了小麦表皮湿润变软易于研磨图表1A。 Gaines et al指出SE和破损面粉出粉率密切相关。

Flour ash content is commonly requested in flour specification for milling and bakingindustries.Yet, it does not consistently give useful information on flour functionality because it ismineral content and depends on both flour extraction percentage and whole wheat ash.Variation inwhole wheat ash is primarily contributed by growing environment rather than by intrinsic grainquality characteristic s (Shuey 1976;Rharrabtietal 2003).To account for variation in whole wheatash between the cultivars,we displayed both flour ash as a content within the flour (Fig 1B)and asa ratio of whole wheat ash(Fig 1D).Reduced ash ratios should indicate better separation of

aleurone from the flour. For all cultivars, 15%tempered moisture reduced flour yield butimproved flour quality as measured by less ash content and PPO activity due to less brancontamination,whereas 12%tempered moisture resulted in greater flour yield and higher ash ratioflour (Fig. 1B–D).The PPO profile had the same trend as ash ratio, in which the reduced temperedwheat moisture contains more bran and more PPO.Although flour PPO was generally correlatedto flour yield within a cultivar, its correlation was poorer than flour ash(Fig. 1B and C).Within acultivar, flour ash was correlated to PPO atr>0.91.

制粉和烘焙行业面粉灰分率通常需要作为面粉的参数。然而通常并没有给有用的信息因为这个仅仅是矿物含量而且取决于面粉出粉率和全麦粉灰分。全麦粉灰分的变化主要是由于生长环境并非谷物本身的质量。为了对于全麦粉的这一变化做出解释我们把面粉灰分作为面粉的一种含量见图表1B也作为全麦粉灰分的一个比例图片1D。减少的灰分率可以表明麦粉蛋白从面粉的分离。对于所有的小麦品种 15%润麦后小麦水分减少了出粉率 同时改善面粉质量 由于少麸少灰分和多酚氧化酶的活性。 12%的润麦小麦水分可以产更高出粉率更高灰分率图表1B-D。多酚氧化酶和灰分率是同样的趋势润麦水分的减少使麸量增多多酚氧化酶增多。通常面粉多酚氧化酶和出粉率有关与灰分的关系不大图表1 B和C。 同一种小麦灰分和多酚氧化酶有关 atr>0.91 。

Within each cultivar, treatment combinations with the 12%tempered wheat moisture treatmentthat increased flour yield consistently decreased in flour quality as measured by ash,ash ratio,orPPO(Fig. 1).Hatcher and Kruger (1993) reported similar results for the low tempered wheattreatment, observing that flour PPO activity and ash content increased with flour extraction rate.This generally was not the case for treatment combinations, including15%tempered wheatmoisture.Overall flour yield was less for the 15%tempered wheat moisture treatments than forpaired treatments invo lving the 12%tempered wheat moisture treatments.However, the treatmentcombinations that increased flour yield within the 15%tempered wheat moisture treatmentstypically did not degrade flour quality,as measured by flour ash,ashratio,or PPO(Fig. 1).对于每种小麦 12%的润麦水分的润麦条件可以增加出粉率 降低面粉质量见图表1。Hatc her和Kruger 曾经报道了有关低润麦水分的情况面粉多酚氧化酶活性和灰分含量随着出粉率提高而降低。对于15%润麦水分的润麦组合并不是这样的。 15%润麦水分总出粉率较12%的较低。然而15%润麦水分会增加出粉率的同时不会降低面粉质量见图表1 .

Effect of Tempered Wheat Moisture on Flour Functionality

润麦水分对面粉质量的影响

Reducing the tempered wheat moisture greatly increased flour yield but also greatlyincreased sodium carbonate SRC(Table II). Similarly, treatments such as tempering temperaturethat only slightly changed flour yield caused negligible changes in sodium carbonate SRC.Generally,with increasing flour yield, lactic acid and sucrose SRC values decreased and sodiumcarbonate SRC increased (Fig. 2B–D). Tempered wheat moisture did not cause a significantchange in water SRC(Fig. 2A).Water SRC values are related to water absorption capacitycontributed by all flour functional components such as glutenins, damaged starch, andarabinoxylans,and represent combined contributions of lactic acid, sodium carbonate,and sucroseSRC values. Tempering treatments that improved flour yield caused off-setting effects ofincreased absorption due to glutenins and damaged starch(increased lactic acid SRC and sodium

- 水分翻译Effect of Tempering Conditions on Milling Performance概要1相关文档

- 本网站Terms & Conditions 协议条款和条件(上)

- swfASHRAE_55_2004_Thermal_Environmental_Conditions_for_Human_Occupancy

- 8.3橘皮书[英文]EPC交钥匙工程合同条件-Conditions of Contract for EPC Turnkey Projects 1999

- 6.Standard Conditions (1992) governing the FIATA MULTIMODAL ...

- transformedlabor conditions in the costa rican sugar industry

- 尤里红色警戒2尤里的复仇单位价格介绍以及建造条件说明(Red Alert 2 Yuri´s revenge is introduced and the construction conditions of the unit price)

百纵科技(1399元/月)香港CN2站群232IP

湖南百纵科技有限公司是一家具有ISP ICP 电信增值许可证的正规公司,多年不断转型探索现已颇具规模,公司成立于2009年 通过多年经营积累目前已独具一格,公司主要经营有国内高防服务器,香港服务器,美国服务器,站群服务器,东南亚服务器租用,国内香港美国云服务器,以及全球专线业务!活动方案:主营:1、美国CN2云服务器,美国VPS,美国高防云主机,美国独立服务器,美国站群服务器,美国母机。2、香港C...

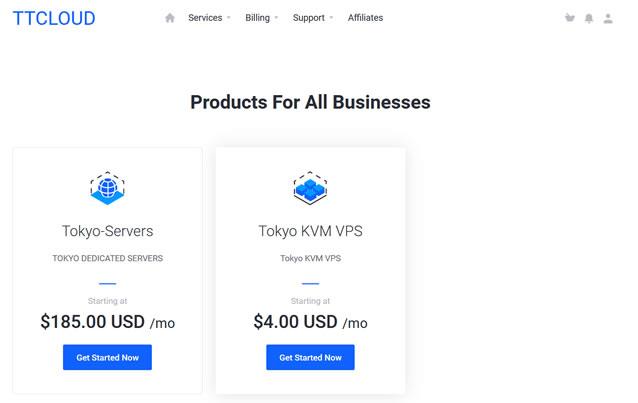

TTcloud(月$70)E3-1270V3 8GB内存 10Mbps带宽 ,日本独立服务器

关于TTCLOUD服务商在今年初的时候有介绍过一次,而且对于他们家的美国圣何塞服务器有过简单的测评,这个服务商主要是提供独立服务器业务的。目前托管硬件已经达到5000台服务器或节点,主要经营圣何塞,洛杉矶以及日本东京三个地区的数据中心业务。这次看到商家有推出了新上架的日本独立服务器促销活动,价格 $70/月起,季付送10Mbps带宽。也可以跟进客户的需求进行各种DIY定制。内存CPU硬盘流量带宽价...

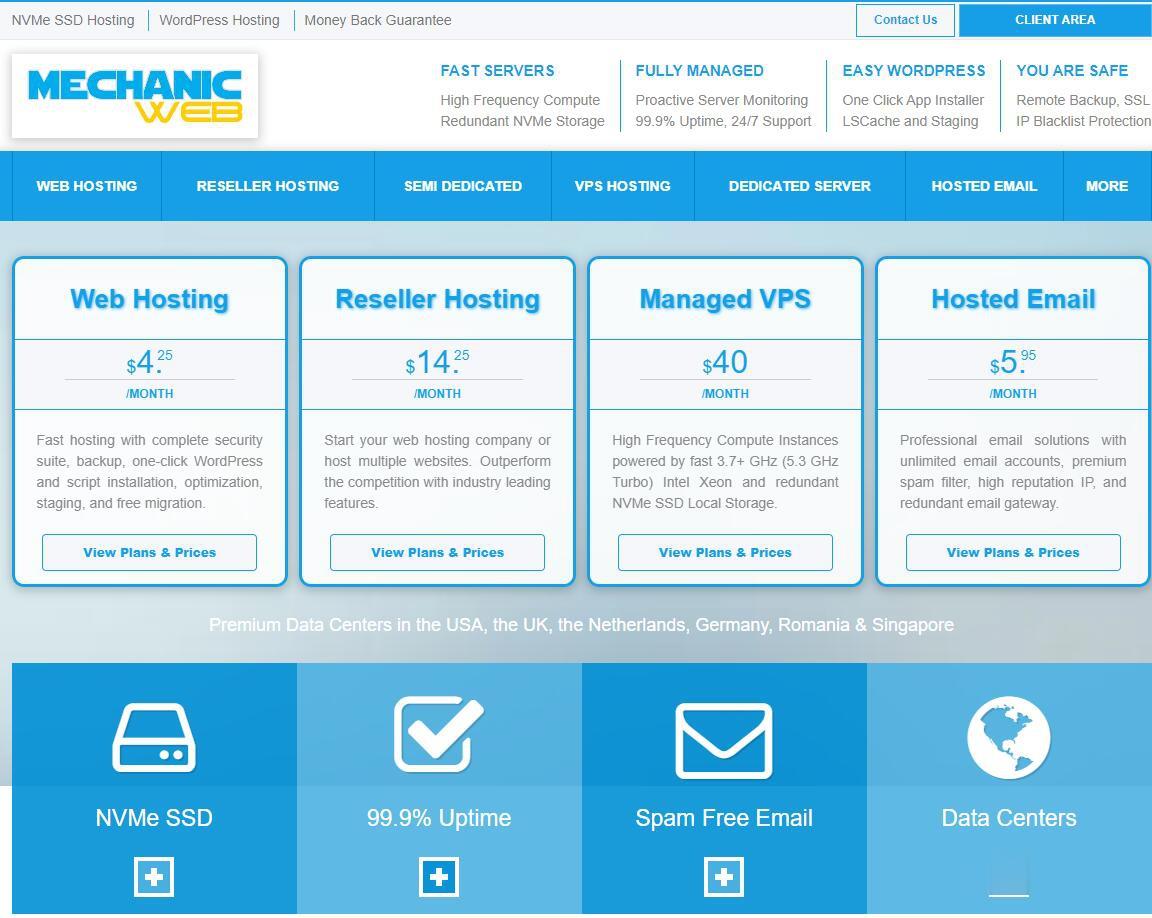

MechanicWeb免费DirectAdmin/异地备份

MechanicWeb怎么样?MechanicWeb好不好?MechanicWeb成立于2008年,目前在美国洛杉矶、凤凰城、达拉斯、迈阿密、北卡、纽约、英国、卢森堡、德国、加拿大、新加坡有11个数据中心,主营全托管型虚拟主机、VPS主机、半专用服务器和独立服务器业务。MechanicWeb只做高端的托管vps,这次MechanicWeb上新Xeon W-1290P处理器套餐,基准3.7GHz最高...

-

网络明星网络明星是怎样成名的呢?如何又是网络明星呢?!!伪静态静态与伪静态的区别?arm开发板ARM开发板和树莓派有什么区别arm开发板新手入门应如何选择 ARM 开发板?arm开发板单片机开发板与ARM开发板有什么不同?9flash在“属性”对话框中的“Move”后面的框中输入Flash动画文件的绝对路径及文件名,这句话怎么操作?迅雷云点播账号求百度云或者迅雷云播账号密码iphone6上市时间苹果6什么时候出来虚拟专用网拨号网络与虚拟专用网的区别系统分析员考系统分析员有什么好处?