hydroxybutyryl77vcd.com

77vcd.com 时间:2021-03-20 阅读:()

UCLAUCLAPreviouslyPublishedWorksTitleEngineeringmetabolicsystemsforproductionofadvancedfuelsPermalinkhttps://escholarship.

org/uc/item/8bn1w585JournalJournalofIndustrialMicrobiology&Biotechnology:OfficialJournaloftheSocietyforIndustrialMicrobiology,36(4)ISSN1476-5535AuthorsYan,YajunLiao,JamesC.

PublicationDate2009-04-01DOI10.

1007/s10295-009-0532-0PeerreviewedeScholarship.

orgPoweredbytheCaliforniaDigitalLibraryUniversityofCaliforniaJIndMicrobiolBiotechnol(2009)36:471–479DOI10.

1007/s10295-009-0532-0123REVIEWEngineeringmetabolicsystemsforproductionofadvancedfuelsYajunYan·JamesC.

LiaoReceived:7December2008/Accepted:14January2009/Publishedonline:7February2009TheAuthor(s)2009.

ThisarticleispublishedwithopenaccessatSpringerlink.

comAbstractThedepletingpetroleumstorageandincreasingenvironmentaldeteriorationarethreateningthesustainabledevelopmentofhumansocieties.

Assuch,biofuelsandchemicalfeedstocksgeneratedfromrenewablesourcesarebecomingincreasinglyimportant.

AlthoughpreviouseVortsledtogreatsuccessinbio-ethanolproduction,higheralco-hols,fattyacidderivativesincludingbiodiesels,alkanes,andalkenesoVeradditionaladvantagesbecauseoftheircompatibilitywithexistinginfrastructure.

Inaddition,someofthesecompoundsareusefulchemicalfeedstocks.

Sincenativeorganismsdonotnaturallyproducethesecom-poundsinhighquantities,metabolicengineeringbecomesessentialinconstructingproducingorganisms.

Inthisarti-cle,webrieXyreviewthefourmajormetabolicsystems,thecoenzyme-Amediatedpathways,theketoacidpathways,thefattyacidpathway,andtheisoprenoidpathways,thatallowproductionofthesefuel-gradechemicals.

IntroductionThedepletingpetroleumreserve,recurringenergycrisis,andglobalclimatechangearereignitingtheenthusiasmforseekingsustainabletechnologiesforreplacingpetroleumasasourceoffuelandchemicals.

Inthepastfewdecades,eVortsinthedevelopmentofbio-ethanolasanalternativefuelhaveledtosigniWcantsuccess[14–16,19].

In2007,6.

5billiongallonsofbio-ethanolwasproducedintheUnitedState[5].

However,bio-ethanolexhibitssomelimitations,suchaslowenergydensity,highvaporpressure,andcorrosiveness,whichpreventitswidespreadutilizationgiventheexistinginfrastructure.

Higheralcohols(withmorethantwocarbons),biodie-sels,andfattyacidderivativesarethoughttobemoresuit-ablefuels.

Theirphysicochemicalpropertiesaremorecompatiblewithgasoline-basedfuelsandallowdirectutili-zationofexistinginfrastructureforstorageanddistribution.

Furthermore,someofthesefuelmoleculesalsoserveasimportantchemicalfeedstocks.

Althoughtheindividualbiochemicalstepsforsynthesizingthesecompoundsinmicrobeshavebeendescribedpreviously,eVortsinputtingtogetherhighlyproductivemetabolicsystemshaveonlybegunrecently.

Inthisarticle,weWrstsummarizethemeta-bolicnetworksforproducingthesecompoundsandthenrevieweVortsinengineeringthenon-nativeproducingorganism,Escherichiacoli.

Themetabolicnetworksdis-cussedincludethetraditionalbutanolpathwayinClostrid-iumspecies,theketoacidpathwaysforhigheralcohols,theisoprenoidpathways,andthefattyacidbiosynthesis.

Thecoenzyme-A-dependentfermentativepathwaysAmongthehigheralcohols,n-butanolandisopropanolaretheonlytwothatareoverproducedinnaturebyClostrid-iumspecies.

n-ButanolhasbeenproducedbyClostridiuminacetone–butanol–ethanol(ABE)fermentation.

Thefer-mentativepathway(Fig.

1)inthisorganismstartsfromacetyl-CoA.

Theenzymeacetyl-CoAacetyltransferase,alsoknownasthiolase,condensestwomoleculesofacetyl-CoAtoonemoleculeofacetoacetyl-CoA.

Fromthismolecule,thepathwaybranchesintoisopropanolandn-butanol.

Fortheisopropanolbiosynthesis,anacetoace-tyl-CoAtransferase(ACoAT)transferstheCoAgroupY.

Yan·J.

C.

Liao(&)DepartmentofChemicalandBiomolecularEngineering,UniversityofCaliforniaatLosAngeles,5531BoelterHall,420WestwoodPlaza,LosAngeles,CA90095,USAe-mail:Liaoj@ucla.

edu472JIndMicrobiolBiotechnol(2009)36:471–479123awayfromacetoacetyl-CoAtoacetateorbutyrate,form-ingacetoacetate.

Theacetyl-CoAisrecycledbacktoace-tatebythecombinedphosphotransacetylaseandacetatekinasereaction.

Further,acetoacetateisdecarboxylatedtoacetonebyanacetoacetatedecarboxylase(ADC).

ThenacetoneisreducedtoisopropanolbyaNADPH-depen-dentsecondaryalcoholdehydrogenase(SADH)[12].

Forn-butanolbiosynthesis,acetoacetatehastogothroughfourstepsofNADH-dependentreductionandonestepofdehydration.

AcetoacetateisWrstreducedto3-hydroxybutyryl-CoAby3-hydroxybutyryl-CoAdehydro-genase(HBD).

Then,3-hydroxybutyryl-CoAisdehydratedtocrotonyl-CoAbyacrotonase(CRT).

Third,abutyryl-CoAdehydrogenase(BCD)catalyzesthereductionofcrotonyl-CoAtobutyryl-CoA.

Finally,analdehyde/alcoholdehydrogenase(AADH)convertsbutyryl-CoAton-butanolthroughtwoconsecutivereductionreactions.

IsopropanolproductioninEscherichiacoliThesecondaryalcohol,isopropanol,isbothadesirablefuelandanimportantchemicalfeedstockinthepetrochemicalindustry.

Itsdehydratedproduct,propylene,servesasthemonomerformakingpolypropylene.

Inaddition,itcanbeusedasanadditivetopetroleum-basedfuels.

Replacingmeth-anolwithisopropanolintheesteriWcationprocessoffatandoilcouldgeneratecrystallization-resistantbiodiesels[12].

Asdescribedabove,isopropanolisproducedbyClos-tridiumspeciesinnature.

However,asanativemetabolite,itcanonlybeproducedinalimitedamountforthehosts'ownbeneWtsasadetoxiWcationresponsetolowpHcondi-tions.

Themaximumtiterreportedinitsnativeproducer,Clostridium,was1.

8g/l[9].

Toimprovetheproductionofisopropanol,thefullycharacterizedisopropanolbiosyn-theticpathway(Fig.

1)wasreconstructedinthegenetictractablehostE.

coli[12].

Escherichiacolihasbeenreportedtoproduceacetone[6],theimmediateprecursorofisopropanol,byexpressingtheintactpathwayfromClostridiumacetobutylicumATCC824consistingoftheacetyl-CoAacyltransferase,ACoAT,ADCencodedbythethl,ctfAB,andadcgenes,respectively.

Thereportedtiterwasaround5.

4g/l,similartotheyieldofnativehostforacetone.

Furthermore,withaSADHco-expressedwiththeacetonepathwayinE.

coli,theisopropanolproductionwasachieved[12].

ThepathwayeYciencywastunedbyusinggenesfromdiVerentorgan-isms,abio-prospectingapproach.

SincethegenesfromClostridiumusuallyhavealowGCcontent,whichmayleadtopoorexpression,theE.

colinativegenesatoBandatoAD,encodingacetyl-CoAacyltransferaseandACoAT,werealsotestedaspathwaycomponents.

Additionally,twogenesfromC.

beijerinckiiNRRLB593andThermoanae-robacterbrockiiHTD4,encodingSADHs,weretotallysynthesizedwithcodonoptimizationandinstalledintothepathwaytotestforproduction.

WiththeseeVorts,thestrainwithacombinationofC.

acetobutylicumthl,E.

coliatoAD,C.

acetobutylicumadc,andC.

beijerinckiiadhachievedthehighesttiter(5.

0g/l).

Theresultispromising,sinceitdemonstrates43.

5%(mol/mol)conversionratio.

Thetheo-reticalyieldis1molisopropanolpermoleglucose.

Theproductionofisopropanolfromglucoseisnotredox-balanced.

FourmolesofNADHisproduced,whileFig.

1Metabolicpathwaysforisopropanoland1-butanolproductioninengineeredE.

coli.

Thedashedlineindicatesomittedsteps.

Isopropanolpathwayconsistsoffourenzymaticstepsfromacetyl-CoA.

1-Butanolpathwayconsistsofsixenzymaticsteps.

aceEFandlpdencodepyruvatedehydrogenase;atoB/thlencodesacetyl-CoAacetyltransferase;ctfAB/atoADencodesacetoacetyl-CoAtransferase;adc,acetoacetatedecarboxylase;sadhencodessecondaryalcoholdehydrogenase;hbdencodes3-hydroxybutyryl-CoAdehydrogenase;crtencodescrotonase;bcdencodesbutyryl-CoAdehydrogenase;etfencodeselectrontransferXavoprotein;adhE2encodesaldehyde/alcoholdehydrogenaseGlucose2Acetyl-CoAAcetoacetyl-CoAAcetoacetateAcetoneIsopropanol3-Hydroxybutyryl-CoACrotonyl-CoAButyryl-CoAButyraldehyden-Butanol2NAD+2NADH2Pyruvate2NAD+2NADH2CO2CoAAcetateAcetyl-CoACO2NADPHNADP+aceEFlpdatoB/thlctfAB/atoADadcsadhNADHNAD+hbdcrtH2ObcdetfNADHNADHNADHNAD+NAD+NAD+adhE2adhE2JIndMicrobiolBiotechnol(2009)36:471–4794731231molofNADPHisconsumedpermoleofisopropanol.

Therefore,anexternalelectronacceptorisrequiredorabyproductisservedasanelectronacceptor.

n-ButanolproductioninE.

colin-Butanolwasproposedtobeoneofthebettersubstitutesforgasoline-basedtransportationfuel,becauseofitshighenergydensityandhydrophobicity.

Itsenergycontent(27MJ/l)issimilartothatofgasoline(32MJ/l).

ThehighhydrophobicityenablesitstransportationandstorageusingexistingpetrochemicalinfrastructurewithminimalmodiW-cation.

Inaddition,n-butanolhasalowvaporpressureof4mmHgat20°C,whichallowsitsmixingwithgasolineatanyratiowithoutexceedingairqualityspeciWcations.

Themicrobialproductionofn-butanolhasahistoryofover100years.

Traditionally,n-butanolisproducedbyClostridiumspeciesthroughtheABEfermentation.

How-ever,n-butanolproductionviathisprocedureisdiYculttocontrolandoptimize,particularlybecauseClostridiumexhibitscomplexphysiologicalfeatures,suchasoxygensensitivity,slowgrowthrate,andspore-forminglifecycles.

Thus,itisdesirabletocreatenewn-butanolproducingorganismsusingmetabolicengineeringtechniques.

Recently,n-butanolproductioninaheterologoushost,E.

coli,usingthetraditionalCoA-dependentpathwayorigi-natedfromC.

acetobutylicum(Fig.

1)wasreportedfortheWrsttime[2].

Atsumietal.

createdtwosyntheticoperonscarryingalltheessentialgenes(thl,hbd,crt,bcd,etfAB,andadhE2)involvedinthepathway.

Co-expressionofthetwooperonsinE.

coliledtotheinitialproductionofn-butanolat14mg/lanaerobicallyusingglucoseassolecar-bonsource.

Tooptimizethepathway,alternativeenzymesofdiVerentoriginswereevaluated.

MorespeciWcally,withE.

coliatoBgeneinplaceofC.

acetobutylicumthl,amorethanthreefoldincreaseofn-butanolproductionwasobserved.

However,replacingtheoriginalenzymesforconversionfromcrotonyl-CoAtobutyryl-CoAwithhomologuesandisoenzymefromMegasphaeraelsdeniiorStreptomycescoelicolorresultedinamuchloweryieldofn-butanolinE.

coli.

Nevertheless,thisresultdoesnotexcludethepossibilityoftheexistenceofothergenesthatmightimproven-butanolproductioninE.

coli.

Furthermore,n-butanolproductiondoesnotsimplyrelyontheenzymeactivities.

TheproductformationalsoneedssuYcientcarbonprecursor,acetyl-CoA,andreducingpower,NADH.

Tofurtherimprovedn-butanolproduction,thehostE.

colistrainwasengineeredbydeletingthenativepathwaycompetingforbothcarbonXuxandreducingpower.

Thebeststraincandidate,namedJCL88,withthedeletionofldhA,adhE,frdBC,pta,andfnr,allowedamorethantwofoldincreaseinn-butanolproduction,accompa-niedbythedramaticdropintheformationoflactate,acetate,ethanol,andsuccinate.

Thehighesttiterof552mg/lwasreportedwithoptimizedpathwayandimprovedstrain.

Althoughtheyieldwasstilllow,thisworkdemonstratedthefeasibilityofheterologousn-butanolproductionandproposedtheprinciplesforfurtheroptimization.

TheketoacidpathwaysImportinganon-nativepathwayinaheterologoushostsuchasE.

coliunavoidablyintroducesnon-nativemetabolitesandpotentialtoxicity,inadditiontodiYcultiesinexpress-ingheterologousenzymes.

Theresultingmetabolicimbal-anceandcytotoxicityposeabarrierforlargequantityproduction.

Inthiscontext,itisdesirabletoseekforthepathwayscompatibletothehost.

Aminoacidbiosynthesisgeneratesmanyketoacidintermediates.

Theseketoacidscanbeconvertedtoalcoholsbyintroducingsequentialdecarboxylationandreductioncatalyzedbybroad-sub-strate-rangeketoaciddecarboxylase(KDC)andalcoholdehydrogenase(ADH)(Fig.

2).

Forexample,theisoleucinebiosynthesispathwaygenerates2-ketobutyrateand2-keto-3-methyl-valerate(KMV),whichcanbeconvertedton-propanoland2-methyl-1-butanol(2MB),respectively.

Thevalinebiosynthesispathwayproduces2-ketoisovalerate(KIV),whichistheprecursorforisobutanol.

Theleucinebiosynthesispathwaygenerates2-keto-4-methyl-pentano-ate,whichisthesubstratefor3-methyl-1-butanol(3MB).

Thephenylalaninebiosynthesispathwayproducesphenyl-pyruvate,whichcanleadto2-phenylethanol.

Thenorvalinebiosynthesispathway,whichisnormallyatoxicside-reactionoftheleucinebiosynthesis,producesasubstrateforn-butanol,2-ketovalerate(KV)[3].

Thesepathwaysrecentlyhavebeenexploredforproductionofthecorre-spondingalcoholsinE.

coliwithencouragingresults.

IsobutanolproductioninE.

coliIsobutanolisanisomerofbutanol.

Ithassimilarphysico-chemicalpropertieston-butanol,whilehavingahigheroctanenumberthann-butanol.

Isobutanolhasbeenidenti-Wedasaminorfermentationproduct,butitshighlevelpro-ductionhasnotbeenreporteduntilrecently[3].

Toachieveisobutanolproductioninalargequantity,thenativeilvIHCDoperonfromE.

coliwasWrstoverexpressedtodivertthecarbonXuxfrompyruvatetoKIV(Fig.

3),whichledtoisobutanolproductionat1.

7g/l,aboutaWvefoldincreaseoverthestrainwithoutilvIHCDoverexpression.

Topreventcarbonleakageandreducepowerwaste,thepreviouslygeneratedknockoutstrainJCL88(adhE,ldhA,frdAB,fnr,pta)wasusedashost;aslightincreaseinisobutanolproduction(2.

2g/l)wasobserved.

Further,alsSfromBacillussubtiliswasusedtoreplace474JIndMicrobiolBiotechnol(2009)36:471–479123E.

coliilvIHforitshighaYnitytowardspyruvate,whichledtotheisobutanolproductionat3.

7g/l.

Inaddition,pXBwasdeletedinstrainJCL88toconservethepyruvateavail-abilityforKIVformation.

WiththecombinationoftheseoverexpressionsandgenomicmodiWcations,theengineeredstrainwasabletoproduceisobutanolatatiterof20g/land86%oftheoreticalyield(Fig.

4)[3].

NotethatisobutanolistoxictoE.

coliataconcentration>10g/l.

Howevertheproductionofisobutanoloccursmainlyinthenon-growingphase(Fig.

4)[3].

Thisresultindicatesthateventhoughthecellscannotgrowatthehigherconcentration,theynonethelesscontinuetoproduceandexcreteisobutanol.

Thus,eventhoughisobutanoltoxic-ityposesachallenge,theproductionlevelcanexceedthetoxicitylevelsigniWcantly.

Mutantswithhigherisobutanoltolerancehavebeenisolated[3],whichalsoimprovestheproductivity.

Suchahigh-yieldproductiondemonstratestheversatilityinexploringtheketoacidpathwaysforbio-fuelproduction.

Theproductionofisobutanol(3.

0.

CO;2-C16.

JarboeLR,GrabarTB,YomanoLP,ShanmuganKT,IngramLO(2007)Developmentofethanologenicbacteria.

AdvBiochemEngBiotechnol108:237–26117.

KalscheuerR,StoltingT,SteinbuchelA(2006)Microdiesel:Escherichiacoliengineeredforfuelproduction.

Microbiology152:2529–2536.

doi:10.

1099/mic.

0.

29028-018.

MagnusonK,JackowskiS,RockCO,CronanJEJr(1993)RegulationoffattyacidbiosynthesisinEscherichiacoli.

Micro-biolRev57:522–54219.

PetersonJD,IngramLO(2008)Anaerobicrespirationinengi-neeredEscherichiacoliwithaninternalelectronacceptortoproducefuelethanol.

AnnNYAcadSci1125:363–372.

doi:10.

1196/annals.

1419.

02020.

RiendeauD,MeighenE(1985)Enzymaticreductionoffattyacidsandacyl-CoAstolongchainaldehydesandalcohols.

Experientia41:707–713.

doi:10.

1007/BF0201256421.

RoDK,ParadiseEM,OuelletM,FisherKJ,NewmanKL,NdunguJM,HoKA,EachusRA,HamTS,KirbyJ,ChangMC,WithersST,ShibaY,SarpongR,KeaslingJD(2006)Productionoftheantimalarialdrugprecursorartemisinicacidinengineeredyeast.

Nature440:940–943.

doi:10.

1038/nature0464022.

SacchettiniJC,PoulterCD(1997)Creatingisoprenoiddiversity.

Science277:1788–1789.

doi:10.

1126/science.

277.

5333.

178823.

ShenCR,LiaoJC(2008)MetabolicengineeringofEscherichiacolifor1-butanoland1-propanolproductionviatheketo-acidpathways.

MetabEng10:312–320.

doi:10.

1016/j.

ymben.

2008.

08.

00124.

WangX,KolattukudyPE(1995)SolubilizationandpuriWcationofaldehyde-generatingfattyacyl-CoAreductasefromgreenalgaBotryococcusbraunii.

FEBSLett370:15–18.

doi:10.

1016/0014-5793(95)00781-425.

WithersST,GottliebSS,LieuB,NewmanJD,KeaslingJD(2007)IdentiWcationofisopentenolbiosyntheticgenesfromBacillussub-tilisbyascreeningmethodbasedonisoprenoidprecursortoxicity.

ApplEnvironMicrobiol73:6277–6283.

doi:10.

1128/AEM.

00861-07

org/uc/item/8bn1w585JournalJournalofIndustrialMicrobiology&Biotechnology:OfficialJournaloftheSocietyforIndustrialMicrobiology,36(4)ISSN1476-5535AuthorsYan,YajunLiao,JamesC.

PublicationDate2009-04-01DOI10.

1007/s10295-009-0532-0PeerreviewedeScholarship.

orgPoweredbytheCaliforniaDigitalLibraryUniversityofCaliforniaJIndMicrobiolBiotechnol(2009)36:471–479DOI10.

1007/s10295-009-0532-0123REVIEWEngineeringmetabolicsystemsforproductionofadvancedfuelsYajunYan·JamesC.

LiaoReceived:7December2008/Accepted:14January2009/Publishedonline:7February2009TheAuthor(s)2009.

ThisarticleispublishedwithopenaccessatSpringerlink.

comAbstractThedepletingpetroleumstorageandincreasingenvironmentaldeteriorationarethreateningthesustainabledevelopmentofhumansocieties.

Assuch,biofuelsandchemicalfeedstocksgeneratedfromrenewablesourcesarebecomingincreasinglyimportant.

AlthoughpreviouseVortsledtogreatsuccessinbio-ethanolproduction,higheralco-hols,fattyacidderivativesincludingbiodiesels,alkanes,andalkenesoVeradditionaladvantagesbecauseoftheircompatibilitywithexistinginfrastructure.

Inaddition,someofthesecompoundsareusefulchemicalfeedstocks.

Sincenativeorganismsdonotnaturallyproducethesecom-poundsinhighquantities,metabolicengineeringbecomesessentialinconstructingproducingorganisms.

Inthisarti-cle,webrieXyreviewthefourmajormetabolicsystems,thecoenzyme-Amediatedpathways,theketoacidpathways,thefattyacidpathway,andtheisoprenoidpathways,thatallowproductionofthesefuel-gradechemicals.

IntroductionThedepletingpetroleumreserve,recurringenergycrisis,andglobalclimatechangearereignitingtheenthusiasmforseekingsustainabletechnologiesforreplacingpetroleumasasourceoffuelandchemicals.

Inthepastfewdecades,eVortsinthedevelopmentofbio-ethanolasanalternativefuelhaveledtosigniWcantsuccess[14–16,19].

In2007,6.

5billiongallonsofbio-ethanolwasproducedintheUnitedState[5].

However,bio-ethanolexhibitssomelimitations,suchaslowenergydensity,highvaporpressure,andcorrosiveness,whichpreventitswidespreadutilizationgiventheexistinginfrastructure.

Higheralcohols(withmorethantwocarbons),biodie-sels,andfattyacidderivativesarethoughttobemoresuit-ablefuels.

Theirphysicochemicalpropertiesaremorecompatiblewithgasoline-basedfuelsandallowdirectutili-zationofexistinginfrastructureforstorageanddistribution.

Furthermore,someofthesefuelmoleculesalsoserveasimportantchemicalfeedstocks.

Althoughtheindividualbiochemicalstepsforsynthesizingthesecompoundsinmicrobeshavebeendescribedpreviously,eVortsinputtingtogetherhighlyproductivemetabolicsystemshaveonlybegunrecently.

Inthisarticle,weWrstsummarizethemeta-bolicnetworksforproducingthesecompoundsandthenrevieweVortsinengineeringthenon-nativeproducingorganism,Escherichiacoli.

Themetabolicnetworksdis-cussedincludethetraditionalbutanolpathwayinClostrid-iumspecies,theketoacidpathwaysforhigheralcohols,theisoprenoidpathways,andthefattyacidbiosynthesis.

Thecoenzyme-A-dependentfermentativepathwaysAmongthehigheralcohols,n-butanolandisopropanolaretheonlytwothatareoverproducedinnaturebyClostrid-iumspecies.

n-ButanolhasbeenproducedbyClostridiuminacetone–butanol–ethanol(ABE)fermentation.

Thefer-mentativepathway(Fig.

1)inthisorganismstartsfromacetyl-CoA.

Theenzymeacetyl-CoAacetyltransferase,alsoknownasthiolase,condensestwomoleculesofacetyl-CoAtoonemoleculeofacetoacetyl-CoA.

Fromthismolecule,thepathwaybranchesintoisopropanolandn-butanol.

Fortheisopropanolbiosynthesis,anacetoace-tyl-CoAtransferase(ACoAT)transferstheCoAgroupY.

Yan·J.

C.

Liao(&)DepartmentofChemicalandBiomolecularEngineering,UniversityofCaliforniaatLosAngeles,5531BoelterHall,420WestwoodPlaza,LosAngeles,CA90095,USAe-mail:Liaoj@ucla.

edu472JIndMicrobiolBiotechnol(2009)36:471–479123awayfromacetoacetyl-CoAtoacetateorbutyrate,form-ingacetoacetate.

Theacetyl-CoAisrecycledbacktoace-tatebythecombinedphosphotransacetylaseandacetatekinasereaction.

Further,acetoacetateisdecarboxylatedtoacetonebyanacetoacetatedecarboxylase(ADC).

ThenacetoneisreducedtoisopropanolbyaNADPH-depen-dentsecondaryalcoholdehydrogenase(SADH)[12].

Forn-butanolbiosynthesis,acetoacetatehastogothroughfourstepsofNADH-dependentreductionandonestepofdehydration.

AcetoacetateisWrstreducedto3-hydroxybutyryl-CoAby3-hydroxybutyryl-CoAdehydro-genase(HBD).

Then,3-hydroxybutyryl-CoAisdehydratedtocrotonyl-CoAbyacrotonase(CRT).

Third,abutyryl-CoAdehydrogenase(BCD)catalyzesthereductionofcrotonyl-CoAtobutyryl-CoA.

Finally,analdehyde/alcoholdehydrogenase(AADH)convertsbutyryl-CoAton-butanolthroughtwoconsecutivereductionreactions.

IsopropanolproductioninEscherichiacoliThesecondaryalcohol,isopropanol,isbothadesirablefuelandanimportantchemicalfeedstockinthepetrochemicalindustry.

Itsdehydratedproduct,propylene,servesasthemonomerformakingpolypropylene.

Inaddition,itcanbeusedasanadditivetopetroleum-basedfuels.

Replacingmeth-anolwithisopropanolintheesteriWcationprocessoffatandoilcouldgeneratecrystallization-resistantbiodiesels[12].

Asdescribedabove,isopropanolisproducedbyClos-tridiumspeciesinnature.

However,asanativemetabolite,itcanonlybeproducedinalimitedamountforthehosts'ownbeneWtsasadetoxiWcationresponsetolowpHcondi-tions.

Themaximumtiterreportedinitsnativeproducer,Clostridium,was1.

8g/l[9].

Toimprovetheproductionofisopropanol,thefullycharacterizedisopropanolbiosyn-theticpathway(Fig.

1)wasreconstructedinthegenetictractablehostE.

coli[12].

Escherichiacolihasbeenreportedtoproduceacetone[6],theimmediateprecursorofisopropanol,byexpressingtheintactpathwayfromClostridiumacetobutylicumATCC824consistingoftheacetyl-CoAacyltransferase,ACoAT,ADCencodedbythethl,ctfAB,andadcgenes,respectively.

Thereportedtiterwasaround5.

4g/l,similartotheyieldofnativehostforacetone.

Furthermore,withaSADHco-expressedwiththeacetonepathwayinE.

coli,theisopropanolproductionwasachieved[12].

ThepathwayeYciencywastunedbyusinggenesfromdiVerentorgan-isms,abio-prospectingapproach.

SincethegenesfromClostridiumusuallyhavealowGCcontent,whichmayleadtopoorexpression,theE.

colinativegenesatoBandatoAD,encodingacetyl-CoAacyltransferaseandACoAT,werealsotestedaspathwaycomponents.

Additionally,twogenesfromC.

beijerinckiiNRRLB593andThermoanae-robacterbrockiiHTD4,encodingSADHs,weretotallysynthesizedwithcodonoptimizationandinstalledintothepathwaytotestforproduction.

WiththeseeVorts,thestrainwithacombinationofC.

acetobutylicumthl,E.

coliatoAD,C.

acetobutylicumadc,andC.

beijerinckiiadhachievedthehighesttiter(5.

0g/l).

Theresultispromising,sinceitdemonstrates43.

5%(mol/mol)conversionratio.

Thetheo-reticalyieldis1molisopropanolpermoleglucose.

Theproductionofisopropanolfromglucoseisnotredox-balanced.

FourmolesofNADHisproduced,whileFig.

1Metabolicpathwaysforisopropanoland1-butanolproductioninengineeredE.

coli.

Thedashedlineindicatesomittedsteps.

Isopropanolpathwayconsistsoffourenzymaticstepsfromacetyl-CoA.

1-Butanolpathwayconsistsofsixenzymaticsteps.

aceEFandlpdencodepyruvatedehydrogenase;atoB/thlencodesacetyl-CoAacetyltransferase;ctfAB/atoADencodesacetoacetyl-CoAtransferase;adc,acetoacetatedecarboxylase;sadhencodessecondaryalcoholdehydrogenase;hbdencodes3-hydroxybutyryl-CoAdehydrogenase;crtencodescrotonase;bcdencodesbutyryl-CoAdehydrogenase;etfencodeselectrontransferXavoprotein;adhE2encodesaldehyde/alcoholdehydrogenaseGlucose2Acetyl-CoAAcetoacetyl-CoAAcetoacetateAcetoneIsopropanol3-Hydroxybutyryl-CoACrotonyl-CoAButyryl-CoAButyraldehyden-Butanol2NAD+2NADH2Pyruvate2NAD+2NADH2CO2CoAAcetateAcetyl-CoACO2NADPHNADP+aceEFlpdatoB/thlctfAB/atoADadcsadhNADHNAD+hbdcrtH2ObcdetfNADHNADHNADHNAD+NAD+NAD+adhE2adhE2JIndMicrobiolBiotechnol(2009)36:471–4794731231molofNADPHisconsumedpermoleofisopropanol.

Therefore,anexternalelectronacceptorisrequiredorabyproductisservedasanelectronacceptor.

n-ButanolproductioninE.

colin-Butanolwasproposedtobeoneofthebettersubstitutesforgasoline-basedtransportationfuel,becauseofitshighenergydensityandhydrophobicity.

Itsenergycontent(27MJ/l)issimilartothatofgasoline(32MJ/l).

ThehighhydrophobicityenablesitstransportationandstorageusingexistingpetrochemicalinfrastructurewithminimalmodiW-cation.

Inaddition,n-butanolhasalowvaporpressureof4mmHgat20°C,whichallowsitsmixingwithgasolineatanyratiowithoutexceedingairqualityspeciWcations.

Themicrobialproductionofn-butanolhasahistoryofover100years.

Traditionally,n-butanolisproducedbyClostridiumspeciesthroughtheABEfermentation.

How-ever,n-butanolproductionviathisprocedureisdiYculttocontrolandoptimize,particularlybecauseClostridiumexhibitscomplexphysiologicalfeatures,suchasoxygensensitivity,slowgrowthrate,andspore-forminglifecycles.

Thus,itisdesirabletocreatenewn-butanolproducingorganismsusingmetabolicengineeringtechniques.

Recently,n-butanolproductioninaheterologoushost,E.

coli,usingthetraditionalCoA-dependentpathwayorigi-natedfromC.

acetobutylicum(Fig.

1)wasreportedfortheWrsttime[2].

Atsumietal.

createdtwosyntheticoperonscarryingalltheessentialgenes(thl,hbd,crt,bcd,etfAB,andadhE2)involvedinthepathway.

Co-expressionofthetwooperonsinE.

coliledtotheinitialproductionofn-butanolat14mg/lanaerobicallyusingglucoseassolecar-bonsource.

Tooptimizethepathway,alternativeenzymesofdiVerentoriginswereevaluated.

MorespeciWcally,withE.

coliatoBgeneinplaceofC.

acetobutylicumthl,amorethanthreefoldincreaseofn-butanolproductionwasobserved.

However,replacingtheoriginalenzymesforconversionfromcrotonyl-CoAtobutyryl-CoAwithhomologuesandisoenzymefromMegasphaeraelsdeniiorStreptomycescoelicolorresultedinamuchloweryieldofn-butanolinE.

coli.

Nevertheless,thisresultdoesnotexcludethepossibilityoftheexistenceofothergenesthatmightimproven-butanolproductioninE.

coli.

Furthermore,n-butanolproductiondoesnotsimplyrelyontheenzymeactivities.

TheproductformationalsoneedssuYcientcarbonprecursor,acetyl-CoA,andreducingpower,NADH.

Tofurtherimprovedn-butanolproduction,thehostE.

colistrainwasengineeredbydeletingthenativepathwaycompetingforbothcarbonXuxandreducingpower.

Thebeststraincandidate,namedJCL88,withthedeletionofldhA,adhE,frdBC,pta,andfnr,allowedamorethantwofoldincreaseinn-butanolproduction,accompa-niedbythedramaticdropintheformationoflactate,acetate,ethanol,andsuccinate.

Thehighesttiterof552mg/lwasreportedwithoptimizedpathwayandimprovedstrain.

Althoughtheyieldwasstilllow,thisworkdemonstratedthefeasibilityofheterologousn-butanolproductionandproposedtheprinciplesforfurtheroptimization.

TheketoacidpathwaysImportinganon-nativepathwayinaheterologoushostsuchasE.

coliunavoidablyintroducesnon-nativemetabolitesandpotentialtoxicity,inadditiontodiYcultiesinexpress-ingheterologousenzymes.

Theresultingmetabolicimbal-anceandcytotoxicityposeabarrierforlargequantityproduction.

Inthiscontext,itisdesirabletoseekforthepathwayscompatibletothehost.

Aminoacidbiosynthesisgeneratesmanyketoacidintermediates.

Theseketoacidscanbeconvertedtoalcoholsbyintroducingsequentialdecarboxylationandreductioncatalyzedbybroad-sub-strate-rangeketoaciddecarboxylase(KDC)andalcoholdehydrogenase(ADH)(Fig.

2).

Forexample,theisoleucinebiosynthesispathwaygenerates2-ketobutyrateand2-keto-3-methyl-valerate(KMV),whichcanbeconvertedton-propanoland2-methyl-1-butanol(2MB),respectively.

Thevalinebiosynthesispathwayproduces2-ketoisovalerate(KIV),whichistheprecursorforisobutanol.

Theleucinebiosynthesispathwaygenerates2-keto-4-methyl-pentano-ate,whichisthesubstratefor3-methyl-1-butanol(3MB).

Thephenylalaninebiosynthesispathwayproducesphenyl-pyruvate,whichcanleadto2-phenylethanol.

Thenorvalinebiosynthesispathway,whichisnormallyatoxicside-reactionoftheleucinebiosynthesis,producesasubstrateforn-butanol,2-ketovalerate(KV)[3].

Thesepathwaysrecentlyhavebeenexploredforproductionofthecorre-spondingalcoholsinE.

coliwithencouragingresults.

IsobutanolproductioninE.

coliIsobutanolisanisomerofbutanol.

Ithassimilarphysico-chemicalpropertieston-butanol,whilehavingahigheroctanenumberthann-butanol.

Isobutanolhasbeenidenti-Wedasaminorfermentationproduct,butitshighlevelpro-ductionhasnotbeenreporteduntilrecently[3].

Toachieveisobutanolproductioninalargequantity,thenativeilvIHCDoperonfromE.

coliwasWrstoverexpressedtodivertthecarbonXuxfrompyruvatetoKIV(Fig.

3),whichledtoisobutanolproductionat1.

7g/l,aboutaWvefoldincreaseoverthestrainwithoutilvIHCDoverexpression.

Topreventcarbonleakageandreducepowerwaste,thepreviouslygeneratedknockoutstrainJCL88(adhE,ldhA,frdAB,fnr,pta)wasusedashost;aslightincreaseinisobutanolproduction(2.

2g/l)wasobserved.

Further,alsSfromBacillussubtiliswasusedtoreplace474JIndMicrobiolBiotechnol(2009)36:471–479123E.

coliilvIHforitshighaYnitytowardspyruvate,whichledtotheisobutanolproductionat3.

7g/l.

Inaddition,pXBwasdeletedinstrainJCL88toconservethepyruvateavail-abilityforKIVformation.

WiththecombinationoftheseoverexpressionsandgenomicmodiWcations,theengineeredstrainwasabletoproduceisobutanolatatiterof20g/land86%oftheoreticalyield(Fig.

4)[3].

NotethatisobutanolistoxictoE.

coliataconcentration>10g/l.

Howevertheproductionofisobutanoloccursmainlyinthenon-growingphase(Fig.

4)[3].

Thisresultindicatesthateventhoughthecellscannotgrowatthehigherconcentration,theynonethelesscontinuetoproduceandexcreteisobutanol.

Thus,eventhoughisobutanoltoxic-ityposesachallenge,theproductionlevelcanexceedthetoxicitylevelsigniWcantly.

Mutantswithhigherisobutanoltolerancehavebeenisolated[3],whichalsoimprovestheproductivity.

Suchahigh-yieldproductiondemonstratestheversatilityinexploringtheketoacidpathwaysforbio-fuelproduction.

Theproductionofisobutanol(3.

0.

CO;2-C16.

JarboeLR,GrabarTB,YomanoLP,ShanmuganKT,IngramLO(2007)Developmentofethanologenicbacteria.

AdvBiochemEngBiotechnol108:237–26117.

KalscheuerR,StoltingT,SteinbuchelA(2006)Microdiesel:Escherichiacoliengineeredforfuelproduction.

Microbiology152:2529–2536.

doi:10.

1099/mic.

0.

29028-018.

MagnusonK,JackowskiS,RockCO,CronanJEJr(1993)RegulationoffattyacidbiosynthesisinEscherichiacoli.

Micro-biolRev57:522–54219.

PetersonJD,IngramLO(2008)Anaerobicrespirationinengi-neeredEscherichiacoliwithaninternalelectronacceptortoproducefuelethanol.

AnnNYAcadSci1125:363–372.

doi:10.

1196/annals.

1419.

02020.

RiendeauD,MeighenE(1985)Enzymaticreductionoffattyacidsandacyl-CoAstolongchainaldehydesandalcohols.

Experientia41:707–713.

doi:10.

1007/BF0201256421.

RoDK,ParadiseEM,OuelletM,FisherKJ,NewmanKL,NdunguJM,HoKA,EachusRA,HamTS,KirbyJ,ChangMC,WithersST,ShibaY,SarpongR,KeaslingJD(2006)Productionoftheantimalarialdrugprecursorartemisinicacidinengineeredyeast.

Nature440:940–943.

doi:10.

1038/nature0464022.

SacchettiniJC,PoulterCD(1997)Creatingisoprenoiddiversity.

Science277:1788–1789.

doi:10.

1126/science.

277.

5333.

178823.

ShenCR,LiaoJC(2008)MetabolicengineeringofEscherichiacolifor1-butanoland1-propanolproductionviatheketo-acidpathways.

MetabEng10:312–320.

doi:10.

1016/j.

ymben.

2008.

08.

00124.

WangX,KolattukudyPE(1995)SolubilizationandpuriWcationofaldehyde-generatingfattyacyl-CoAreductasefromgreenalgaBotryococcusbraunii.

FEBSLett370:15–18.

doi:10.

1016/0014-5793(95)00781-425.

WithersST,GottliebSS,LieuB,NewmanJD,KeaslingJD(2007)IdentiWcationofisopentenolbiosyntheticgenesfromBacillussub-tilisbyascreeningmethodbasedonisoprenoidprecursortoxicity.

ApplEnvironMicrobiol73:6277–6283.

doi:10.

1128/AEM.

00861-07

- hydroxybutyryl77vcd.com相关文档

- identity77vcd.com

- 功能77vcd.com

- 选择77vcd.com

- Signature77vcd.com

- 本文件已经我单位审核,请按此文件发布!

- CY77vcd.com

cyun29元/月,香港CN2 GIA云服务器低至起;香港多ip站群云服务器4核4G

cyun怎么样?cyun蓝米数据是一家(香港)藍米數據有限公司旗下品牌,蓝米云、蓝米主机等同属于该公司品牌。CYUN全系列云产品采用KVM架构,SSD磁盘阵列,优化线路,低延迟,高稳定。目前,cyun推出的香港云服务器性价比超高,香港cn2 gia云服务器,1核1G1M/系统盘+20G数据盘,低至29元/月起;香港多ip站群云服务器,16个ip/4核4G仅220元/月起,希望买香港站群服务器的站长...

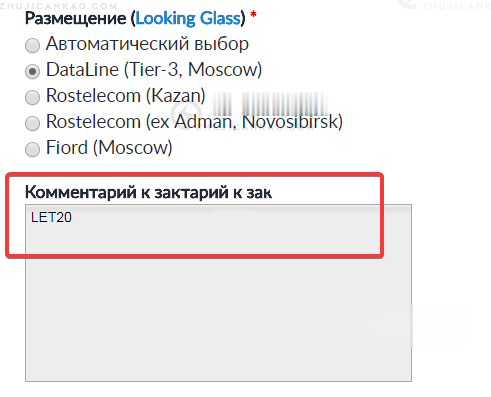

JustHost,最新高性价比超便宜俄罗斯CN2 VPS云服务器终身8折优惠,最低仅8元/月起,200Mbps带宽不限流量,五大机房自助自由切换,免费更换IP,俄罗斯cn2vps怎么样,justhost云服务器速度及综合性能详细测评报告

主机参考最新消息:JustHost怎么样?JustHost服务器好不好?JustHost好不好?JustHost是一家成立于2006年的俄罗斯服务器提供商,支持支付宝付款,服务器价格便宜,200Mbps大带宽不限流量,支持免费更换5次IP,支持控制面板自由切换机房,目前JustHost有俄罗斯5个机房可以自由切换选择,最重要的还是价格真的特别便宜,最低只需要87卢布/月,约8.5元/月起!just...

RAKsmart:美国洛杉矶独服,E3处理器/16G/1TB,$76.77/月;美国/香港/日本/韩国站群服务器,自带5+253个IPv4

RAKsmart怎么样?RAKsmart机房即日起开始针对洛杉矶机房的独立服务器进行特别促销活动:低至$76.77/月,最低100Mbps带宽,最高10Gbps带宽,优化线路,不限制流量,具体包括有:常规服务器、站群服务器、10G大带宽服务器、整机机柜托管。活动截止6月30日结束。RAKsmart,美国华人老牌机房,专注于圣何塞服务器,有VPS、独立服务器等。支持PayPal、支付宝付款。点击直达...

77vcd.com为你推荐

-

汇通物流汇通快递好吗公司网络被攻击公司的一个员工手机中病毒了,今天公司网络被攻击大家的手机都上不了网,说是有人在扫描我们的无线网,h连锁酒店连锁酒店有哪些同ip网站查询服务器禁PING 是不是就可以解决同IP网站查询问题地陷裂口山崩地裂的意思罗伦佐娜手上鸡皮肤怎么办,维洛娜毛周角化修复液同一服务器网站一个服务器能运行多少个网站8090lu.com《8090》节目有不有高清的在线观看网站啊?m.2828dy.comwww.dy6868.com这个电影网怎么样?555sss.comms真的是500万像素?