Assembliesblaze

blaze 时间:2021-01-12 阅读:()

CAFCOBLAZE-SHIELDHPisaninorganic,portlandcementbased,mediumdensitySpray-AppliedFireResistiveMaterial(SFRM)designedtoprovideprotec-tionforstructuralsteelincommercialconstruction.

CAFCOBLAZE-SHIELDHP'sdurablesurfaceandcementbasedformulaenableittowithstandindirectweatherexposureconditionsandlimitedphysicalabuse,thusallowingforapplicationinparkinggarages,mechani-calroomsandelevatorshafts.

CAFCOBLAZE-SHIELDHPhasbeentestedandisclassi-fiedas"investigatedforexterioruse"byUnderwritersLaboratories,Inc.

Withasimpleone-stepapplicationprocess,CAFCOBLAZE-SHIELDHPisabletoprovidecompletepassivefireprotectionformostconstructionconditionsatreducedcostsandinlesstime.

CAFCOBLAZE-SHIELDHPSpray-AppliedFireResistiveMaterialCODECOMPLIANCESCAFCOBLAZE-SHIELDHPsatisfiestherequirementsofthefollowing:IBC-InternationalBuildingCode(ICCESR-1649)NewYorkCity—MEANBC-NationalBuildingCodeofCanadaPhysicalPerformanceCharacteristicASTMMethodStandardPerformance*TestedPerformance**DensityE60522pcf(352kg/m3)24-26pcf(384-416kg/m3)CombustibilityE136NoncombustibleNoncombustibleCohesion/AdhesionE736434psf(20.

8kPa)1,525psf(73kPa)DeflectionE759NoCracksorDelaminationsNoCracksorDelaminationsBondImpactE760NoCracksorDelaminationsNoCracksorDelaminationsCompressiveStrengthE7617,344psf(351kPa)7,980psf(382kPa)AirErosionResistanceE859Lessthan0.

025g/ft2(0.

27g/m2)0.

000g/ft2(0.

000g/m2)CorrosionResistanceE937,Mil.

Std.

810DoesNotPromoteCorrosionofSteelDoesNotPromoteCorrosionofSteelFungalResistanceG21NoGrowthAfter28DaysPassed.

*StandardperformancebasedonGeneralServicesAdministrationAIA/SC/GSA/07811exceptfordensity,whichisbasedonUL.

RefertoULdesignfordensityrequirement.

**ValuesrepresentindependentlaboratorytestsundercontrolledconditionsTHERMALPROPERTIESTheuniqueformulationofCAFCOBLAZE-SHIELDHPmakesitaveryeffectivethermalinsulator.

Thisbenefitisimportantinreducingheatloss,particularlywhenappliedtotheundersideofaroofdeck.

TheR-valueaddedbyCAFCOBLAZE-SHIELDHPmayallowareductioninroofinsulation.

ProductConductivity(k)*Resistance(R/inch)BLAZE-SHIELDHP0.

41BTUin/hrft2°F@75°F2.

43(0.

059W/mK@24°C)*WhentestedinaccordancewithASTMC518ACOUSTICALPROPERTIESAsanefficientsound-absorbingmaterial,CAFCOBLAZE-SHIELDHPaddsvaluetothefireprotectionapplicationinareaswherehigh-noiselevelsareanticipated.

Typicalacousticalperformanceisasfollows:ProductThicknessBaseNRCRating*BLAZE-SHIELDHP1/2inch(13mm)Deck&Beam0.

85*WhentestedinaccordancewithASTMC423CAFCOBLAZE-SHIELDHPcomplieswiththerequirementsofthefollowingspecifications:GeneralServicesAdministration(GSA):AIA/SC/GSA:07811MAJORSPECIFICATIONSDepartmentoftheNavyNAVFACENGCOMGuideSpecificationNFGS07810,Sprayed-OnFireproofingVeteransAdministration(VA):H-08-1U.

S.

ARMYCorpsofEngineers.

CEGS-07811U.

S.

EnvironmentalProtectionAgency(EPA):Regulation40ConstructionSpecificationCanada(CSC)TEK-AIDFactoryMutualApprovedFIRETESTPERFORMANCECAFCOBLAZE-SHIELDHPhasbeenextensivelytestedforfireendurancebyUnderwritersLaboratories,Inc.

(UL)andUnderwritersLaboratoriesofCanada(ULC)inaccordancewithASTME119(UL263,CAN/ULC-S101).

Thesetestshaveresultedinratingsofupto4hoursfor:FloorAssembliesBeamsJoistsColumnsRoofAssembliesWallsandPartitionsCAFCOBLAZE-SHIELDHPhasalsobeentestedinaccordancewithASTME84andCAN/ULC-S102andhasthefollowingSurfaceBurningCharacteristics:FlameSpread.

0SmokeDeveloped0CAFCOBLAZE-SHIELDHPGuideSpecificationPART1–GENERAL1.

1WorkIncluded1.

1.

1Providealllabor,materials,equipmentandservicesnecessaryfor,andincidentalto,thecompleteandproperinstallationofallspray-appliedfireresistivematerialandrelatedworkasshownonthedrawingsorwherespecifiedherein,andinaccordancewithallapplicablerequirementsoftheContractDocuments.

1.

1.

2Thematerialandinstallationshallconformtotheapplicablebuildingcoderequirementsandtherequire-mentsofallauthoritieshavingjurisdiction.

1.

2QualityAssurance1.

2.

1Workshallbeperformedbyafirmwithexpertiseintheinstallationoffireprotectionorsimilarmaterials.

Thisfirmshallbelicensedorotherwiseapprovedbythespray-appliedfireresistivematerialmanufacturer.

1.

2.

2Beforeproceedingwiththefireprotectionwork,approvaloftheproposedmaterialthicknessesanddensitiesshallbeobtainedfromthearchitectandotherapplicableauthoritieshavingjurisdiction.

1.

3RelatedSections1.

3.

1Section05100-StructuralSteel.

1.

3.

2Section05300-MetalDecking.

1.

3.

3Section07200-Insulation.

1.

3.

4Section07270-Firestopping.

1.

3.

5Section07812-IntumescentCoatings.

1.

3.

6Section09200-LathandPlaster.

1.

3.

7Section09900-Painting.

1.

4ReferencesA.

ASTME84-SurfaceBurningCharacteristicsofBuildingMaterials.

B.

ASTME119-FireTestsofBuildingConstructionandMaterials.

C.

ASTME136-(Noncombustibility)BehaviorofMaterialsinaVerticalTubeFurnaceat750C.

D.

ASTME605-ThicknessandDensityofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

E.

ASTME736-Cohesion/AdhesionofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

F.

ASTME759-EffectofDeflectionofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

G.

ASTME760-EffectofImpactonBondingofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

H.

ASTME761-CompressiveStrengthofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

I.

ASTME859-AirErosionofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

J.

ASTME937-CorrosionofSteelbySprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

K.

CAN/ULC-S101-StandardMethodsofFireTestsofBuildingConstructionandMaterials.

L.

CAN/ULC-S102SteinerTunnelTest.

M.

CAN4-S114StandardTestMethodforDeterminationofNoncombustibilityinBuildingMaterials.

1.

4.

1UnderwritersLaboratories,Inc.

(UL)FireResistanceDirectory.

1.

4.

2UnderwritersLaboratoriesofCanada(ULC)ListofEquipmentandMaterials.

1.

4.

3UniformBuildingCodeStandardNo.

7-6(currentedition):ThicknessandDensityDeterminationforSpray-AppliedFireProtection.

1.

4.

4AWCIPublication:TechnicalManual12-AStandardPracticefortheTestingandInspectionofFieldAppliedSprayedFire-ResistiveMaterials;anAnnotatedGuide.

1.

5Submittals1.

5.

1Manufacturer'sData:Submitmanufacturer'sspecifications,includingcertificationasmayberequiredtoshowmaterialcompliancewithContractDocuments.

1.

5.

2TestData:Independentlaboratorytestresultsshallbesubmittedforallspecifiedperformancecriteria.

1.

6Delivery,StorageandHandling1.

6.

1Delivermaterialstotheprojectinmanufacturer'sunopenedpackages,fullyidentifiedastotradename,typeandotheridentifyingdata.

PackagingshallbeartheULandULClabelsforfirehazardandfire-resist-anceclassifications.

1.

6.

2Storematerialsaboveground,inadrylocation,protectedfromtheweather.

Damagedpackagesfoundunsuitableforuseshouldberejectedandremovedfromtheproject.

1.

7ProjectConditions1.

7.

1Whentheprevailingoutdoortemperatureatthebuild-ingislessthan40°F(4°C),aminimumsubstrateandambienttemperatureof40°F(4°C)shallbemaintainedpriorto,during,andaminimumof24hoursafterapplicationofspray-appliedfireresis-tivematerial.

IfnecessaryforjobprogressGeneralContractorshallprovideenclosuresandheattomain-tainpropertemperaturesandhumiditylevels.

1.

7.

2GeneralContractorshallprovideventilationtoallowproperdryingofthespray-appliedfireresistivematerialduringandsubsequenttoitsapplication.

1.

7.

2.

1Inenclosedareasventilationshallnotbelessthan4completeairchangesperhour.

1.

8Sequencing/Scheduling1.

8.

1Allfireprotectionworkonafloorshallbecompletedbeforeproceedingtothenextfloor.

1.

8.

2TheContractorshallcooperateinthecoordinationandschedulingoffireprotectionworktoavoiddelaysinjobprogress.

PART2–PRODUCTS2.

1AcceptableManufacturers.

Thespray-appliedfireresistivematerialshallbemanufacturedundertheCAFCObrandname,byauthorizedproducers.

2.

2Materials2.

2.

1MaterialsshallbeBLAZE-SHIELDHP,(UL/ULCdesignation:TypeHP)appliedtoconformtothedrawings,specificationsandfollowingtestcriteria:2.

2.

1.

1Deflection:WhentestedinaccordancewithASTME759,thematerialshallnotcrackordelaminatewhenthenon-concretetoppedgalvanizeddecktowhichitisappliedissubjectedtoaonetimeverticalcenterloadresultinginadownwarddeflectionof1/120thofthespan.

2.

2.

1.

2BondImpact:WhentestedinaccordancewithASTME760,thematerialshallnotcrackordelaminatefromtheconcretetoppedgalvanizeddecktowhichitisapplied.

2.

2.

1.

3Cohesion/Adhesion(bondstrength):WhentestedinaccordancewithASTME736,thematerialappliedoveruncoatedorgalvanizedsteelshallhaveanaveragebondstrengthof434psf(20.

8kPa).

2.

2.

1.

4AirErosion:WhentestedinaccordancewithASTME859,thematerialshallnotbesubjecttolossesfromthefinishedapplicationgreaterthan0.

025gramspersq.

ft.

(0.

27gramspersquaremeter).

2.

2.

1.

5CompressiveStrength:WhentestedinaccordancewithASTME761,thematerialshallnotdeformmorethan10percentwhensubjectedtoacrushingforceof7,344psf(351kPa).

2.

2.

1.

6CorrosionResistance:WhentestedinaccordancewithASTME937,thematerialshallnotpromotecorrosionofsteel.

2.

2.

1.

7Noncombustibility:WhentestedinaccordancewithASTME136orCAN4-S114,thematerialshallbenon-combustible.

2.

2.

1.

8SurfaceBurningCharacteristics:WhentestedinaccordancewithASTME84orCAN/ULC-S102,thematerialshallexhibitthefollowingsurfaceburningcharacteristics:FlameSpread.

0SmokeDeveloped.

.

.

.

.

02.

2.

1.

9Density:WhentestedinaccordancewithASTME605,thematerialshallmeettheminimumindividualandaveragedensityvaluesaslistedintheappropriateUL/ULCdesignorasrequiredbytheauthorityhavingjurisdiction.

2.

2.

2ThematerialshallhavebeentestedandclassifiedbyUnderwritersLaboratories,Inc.

(UL)orUnderwritersLaboratoriesofCanada(ULC)inaccordancewiththeproceduresofUL263(ASTME119)orCAN/ULC-S101.

2.

2.

3Spray-appliedfireresistivematerialsshallbeappliedattheapprovedminimumthicknessanddensitytoachievethefollowingratings:Floorassemblies___hr.

Roofassemblies___hr.

Beams___hr.

Girders___hr.

Columns___hr.

Joists___hr.

2.

2.

4Potablewatershallbeusedfortheapplicationofspray-appliedfireresistivematerials.

2.

2.

5Spray-appliedfireresistivematerialsshallcontainnodetectableasbestos.

PART3–EXECUTION3.

1Preparation3.

1.

1Allsurfacestoreceivefireprotectionshallbefreeofoil,grease,loosemillscale,dirt,paints/primersorotherforeignmaterialswhichwouldimpairsatisfacto-rybondingtothesurface.

Manufacturershallbecon-tactedforproceduresonhandlingprimed/paintedsteel.

Anycleaningofsurfacestoreceivespray-appliedfireresistivematerialshallbetheresponsibili-tyoftheGeneralContractororSteelErector,asout-linedinthestructuralsteelorsteeldecksection.

3.

1.

2Clips,hangers,supports,sleevesandotherattach-mentstothesubstratearetobeplacedbyotherspriortotheapplicationofspray-appliedfireresistivemate-rials.

3.

1.

3Theinstallationofducts,piping,conduitorothersuspendedequipmentshallnottakeplaceuntiltheapplicationofspray-appliedfireresistivematerialiscompleteinanarea.

3.

1.

4Thespray-appliedfireresistivematerialshallonlybeappliedtosteeldeckwhichhasbeenfabricatedanderectedinaccordancewiththecriteriasetbytheSteelDeckInstitute.

3.

1.

5Whenrooftrafficisanticipated,asinthecaseofperi-odicmaintenance,roofingpaversshallbeinstalledasawalkwaytodistributeloads.

3.

2Application3.

2.

1Equipment,mixingandapplicationshallbeinaccordancewiththemanufacturer'swrittenapplicationinstructions.

3.

2.

2Theapplicationofspray-appliedfireresistivematerialshallnotcommenceuntilcertificationhasbeenreceivedbytheGeneralContractorthatsurfacestoreceivespray-appliedfireresistivemateri-alhavebeeninspectedbytheapplicatorandareacceptabletoreceivespray-appliedfireresistivematerial.

3.

2.

3AllunsuitablesubstratesmustbeidentifiedandmadeknowntotheGeneralContractorandcorrectedpriortoapplicationofthespray-appliedfireresistivematerial.

3.

2.

4Spray-appliedfireresistivematerialshallnotbeappliedtosteelfloordeckspriortothecompletionofconcreteworkonthatdeck.

3.

2.

5Theapplicationofspray-appliedfireresistivematerialtotheundersideofroofdeckshallnotcommenceuntiltheroofingiscompletelyinstalledandtight,allpenthousesarecomplete,allmechanicalunitshavebeenplaced,andafterconstructionrooftraffichasceased.

3.

2.

6Propertemperatureandventilationshallbemaintainedasspecifiedin1.

7.

1,1.

7.

2and1.

7.

2.

1.

3.

2.

7Providemasking,dropclothsorothersuitablecoveringstopreventoversprayfromcomingincontactwithsurfacesnotintendedtobesprayed.

3.

2.

8CAFCOBOND-SEAL(TypeEBS)adhesiveshallbeappliedaspertheappropriateUL/ULCfireresistancedesignandmanufacturer'swrittenrecommendations.

3.

3RepairingandCleaning3.

3.

1Allpatchingofandrepairtospray-appliedfireresis-tivematerial,duetodamagebyothertrades,shallbeperformedunderthissectionandpaidforbythetraderesponsibleforthedamage.

3.

3.

2Afterthecompletionoftheworkinthissection,equipmentshallberemovedandallsurfacesnottobesprayedshallbecleanedtotheextentpreviouslyagreedtobytheapplicatorandGeneralContractor.

3.

4InspectionandTesting3.

4.

1Thespray-appliedfireresistivematerialshallbetestedforthicknessanddensityinaccordancewithoneofthefollowingprocedures:ASTME605-StandardTestMethodofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

AWCI-TechnicalManual12-AStandardPracticefortheTestingandInspectionofFieldAppliedSprayedFire-ResistiveMaterialsanAnnotatedGuide.

UBCStandardNo.

7-6-ThicknessandDensityDeterminationforSpray-AppliedFireProtection.

ProductAvailabilityIsolatekInternationalSpray-AppliedFireResistiveMaterialsareavailabletotrained,licensedcontractorsaroundtheworldfromstrategicallylocatedproductionanddistributionpointsintheU.

S.

,Canada,Mexico,EuropeandthePacificBasin.

ISOLATEKINTERNATIONALisregisteredwiththeAIAContinuingEducationSystem(AIA/CES)ForFurtherInformationCAFCOTechnicalandSalesRepresentativesarealwaysavailabletolendassistance.

Additionalprintedmaterials,includingMaterialSafetyDataSheets,andotherproductliterature,areavailableuponrequest.

FormoreinformationaboutourCAFCOlineofsprayedfireprotection,thermalandacousticaltreatments,IntumescentCoatings,thermalbarriersandCAFCO-BOARDorforthenameoftheSalesRepresentativeinyourarea,pleasecontact:Formoredetailedproductinformation,visitourwebsiteatwww.

cafco.

comorcontactusattechnical@isolatek.

comTheperformancedatahereinreflectourexpectationsbasedontestsconductedinaccordancewithrecognizedstandardmethodsundercontrolledconditions.

Theapplicator,generalcontractor,propertyownerand/oruserMUSTread,understandandfollowthedirections,specificationsand/orrecommendationssetforthinIsolatekInternational'spublicationsconcerninguseandapplicationoftheseproducts,andshouldnotrelymerelyontheinformationcontainedinthisproductdatasheet.

IsolatekInternationalisnotresponsibleforpropertydamage,bodilyinjuries,consequentialdamages,orlossesofanykindthatarisefromorarerelatedtotheapplicator's,generalcontractor's,orpropertyowner'sfailuretofollowtherecommendationssetforthinIsolatekInternational'spublications.

ThesaleoftheseproductsshallbesubjecttotheTermsandConditionsofSalesetforthintheCompany'sinvoices.

IntheUnitedStates:IsolatekInternational,Stanhope,NewJerseyTel:800.

631.

9600Fax:973.

347.

9170InMexico&CentralAmerica:CafcoMexicoS.

A.

deC.

V.

,MexicoD.

F.

Tel:525.

254.

6683Fax:525.

531.

7826InAndeanCountries:CafcoAndinaS.

A.

,Santiago,ChileTel:562.

719.

0394InCanada:CafcoIndustries,Toronto(Ontario)Tel:888.

873.

0003Fax:416.

679.

2933InAsia/Pacfic:Tel:60.

3.

5121.

3886Fax:60.

3.

5121.

4886TotalPassiveFireProtectionISOLATEKInternationalAllRightsReserved9/11

CAFCOBLAZE-SHIELDHP'sdurablesurfaceandcementbasedformulaenableittowithstandindirectweatherexposureconditionsandlimitedphysicalabuse,thusallowingforapplicationinparkinggarages,mechani-calroomsandelevatorshafts.

CAFCOBLAZE-SHIELDHPhasbeentestedandisclassi-fiedas"investigatedforexterioruse"byUnderwritersLaboratories,Inc.

Withasimpleone-stepapplicationprocess,CAFCOBLAZE-SHIELDHPisabletoprovidecompletepassivefireprotectionformostconstructionconditionsatreducedcostsandinlesstime.

CAFCOBLAZE-SHIELDHPSpray-AppliedFireResistiveMaterialCODECOMPLIANCESCAFCOBLAZE-SHIELDHPsatisfiestherequirementsofthefollowing:IBC-InternationalBuildingCode(ICCESR-1649)NewYorkCity—MEANBC-NationalBuildingCodeofCanadaPhysicalPerformanceCharacteristicASTMMethodStandardPerformance*TestedPerformance**DensityE60522pcf(352kg/m3)24-26pcf(384-416kg/m3)CombustibilityE136NoncombustibleNoncombustibleCohesion/AdhesionE736434psf(20.

8kPa)1,525psf(73kPa)DeflectionE759NoCracksorDelaminationsNoCracksorDelaminationsBondImpactE760NoCracksorDelaminationsNoCracksorDelaminationsCompressiveStrengthE7617,344psf(351kPa)7,980psf(382kPa)AirErosionResistanceE859Lessthan0.

025g/ft2(0.

27g/m2)0.

000g/ft2(0.

000g/m2)CorrosionResistanceE937,Mil.

Std.

810DoesNotPromoteCorrosionofSteelDoesNotPromoteCorrosionofSteelFungalResistanceG21NoGrowthAfter28DaysPassed.

*StandardperformancebasedonGeneralServicesAdministrationAIA/SC/GSA/07811exceptfordensity,whichisbasedonUL.

RefertoULdesignfordensityrequirement.

**ValuesrepresentindependentlaboratorytestsundercontrolledconditionsTHERMALPROPERTIESTheuniqueformulationofCAFCOBLAZE-SHIELDHPmakesitaveryeffectivethermalinsulator.

Thisbenefitisimportantinreducingheatloss,particularlywhenappliedtotheundersideofaroofdeck.

TheR-valueaddedbyCAFCOBLAZE-SHIELDHPmayallowareductioninroofinsulation.

ProductConductivity(k)*Resistance(R/inch)BLAZE-SHIELDHP0.

41BTUin/hrft2°F@75°F2.

43(0.

059W/mK@24°C)*WhentestedinaccordancewithASTMC518ACOUSTICALPROPERTIESAsanefficientsound-absorbingmaterial,CAFCOBLAZE-SHIELDHPaddsvaluetothefireprotectionapplicationinareaswherehigh-noiselevelsareanticipated.

Typicalacousticalperformanceisasfollows:ProductThicknessBaseNRCRating*BLAZE-SHIELDHP1/2inch(13mm)Deck&Beam0.

85*WhentestedinaccordancewithASTMC423CAFCOBLAZE-SHIELDHPcomplieswiththerequirementsofthefollowingspecifications:GeneralServicesAdministration(GSA):AIA/SC/GSA:07811MAJORSPECIFICATIONSDepartmentoftheNavyNAVFACENGCOMGuideSpecificationNFGS07810,Sprayed-OnFireproofingVeteransAdministration(VA):H-08-1U.

S.

ARMYCorpsofEngineers.

CEGS-07811U.

S.

EnvironmentalProtectionAgency(EPA):Regulation40ConstructionSpecificationCanada(CSC)TEK-AIDFactoryMutualApprovedFIRETESTPERFORMANCECAFCOBLAZE-SHIELDHPhasbeenextensivelytestedforfireendurancebyUnderwritersLaboratories,Inc.

(UL)andUnderwritersLaboratoriesofCanada(ULC)inaccordancewithASTME119(UL263,CAN/ULC-S101).

Thesetestshaveresultedinratingsofupto4hoursfor:FloorAssembliesBeamsJoistsColumnsRoofAssembliesWallsandPartitionsCAFCOBLAZE-SHIELDHPhasalsobeentestedinaccordancewithASTME84andCAN/ULC-S102andhasthefollowingSurfaceBurningCharacteristics:FlameSpread.

0SmokeDeveloped0CAFCOBLAZE-SHIELDHPGuideSpecificationPART1–GENERAL1.

1WorkIncluded1.

1.

1Providealllabor,materials,equipmentandservicesnecessaryfor,andincidentalto,thecompleteandproperinstallationofallspray-appliedfireresistivematerialandrelatedworkasshownonthedrawingsorwherespecifiedherein,andinaccordancewithallapplicablerequirementsoftheContractDocuments.

1.

1.

2Thematerialandinstallationshallconformtotheapplicablebuildingcoderequirementsandtherequire-mentsofallauthoritieshavingjurisdiction.

1.

2QualityAssurance1.

2.

1Workshallbeperformedbyafirmwithexpertiseintheinstallationoffireprotectionorsimilarmaterials.

Thisfirmshallbelicensedorotherwiseapprovedbythespray-appliedfireresistivematerialmanufacturer.

1.

2.

2Beforeproceedingwiththefireprotectionwork,approvaloftheproposedmaterialthicknessesanddensitiesshallbeobtainedfromthearchitectandotherapplicableauthoritieshavingjurisdiction.

1.

3RelatedSections1.

3.

1Section05100-StructuralSteel.

1.

3.

2Section05300-MetalDecking.

1.

3.

3Section07200-Insulation.

1.

3.

4Section07270-Firestopping.

1.

3.

5Section07812-IntumescentCoatings.

1.

3.

6Section09200-LathandPlaster.

1.

3.

7Section09900-Painting.

1.

4ReferencesA.

ASTME84-SurfaceBurningCharacteristicsofBuildingMaterials.

B.

ASTME119-FireTestsofBuildingConstructionandMaterials.

C.

ASTME136-(Noncombustibility)BehaviorofMaterialsinaVerticalTubeFurnaceat750C.

D.

ASTME605-ThicknessandDensityofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

E.

ASTME736-Cohesion/AdhesionofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

F.

ASTME759-EffectofDeflectionofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

G.

ASTME760-EffectofImpactonBondingofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

H.

ASTME761-CompressiveStrengthofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

I.

ASTME859-AirErosionofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

J.

ASTME937-CorrosionofSteelbySprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

K.

CAN/ULC-S101-StandardMethodsofFireTestsofBuildingConstructionandMaterials.

L.

CAN/ULC-S102SteinerTunnelTest.

M.

CAN4-S114StandardTestMethodforDeterminationofNoncombustibilityinBuildingMaterials.

1.

4.

1UnderwritersLaboratories,Inc.

(UL)FireResistanceDirectory.

1.

4.

2UnderwritersLaboratoriesofCanada(ULC)ListofEquipmentandMaterials.

1.

4.

3UniformBuildingCodeStandardNo.

7-6(currentedition):ThicknessandDensityDeterminationforSpray-AppliedFireProtection.

1.

4.

4AWCIPublication:TechnicalManual12-AStandardPracticefortheTestingandInspectionofFieldAppliedSprayedFire-ResistiveMaterials;anAnnotatedGuide.

1.

5Submittals1.

5.

1Manufacturer'sData:Submitmanufacturer'sspecifications,includingcertificationasmayberequiredtoshowmaterialcompliancewithContractDocuments.

1.

5.

2TestData:Independentlaboratorytestresultsshallbesubmittedforallspecifiedperformancecriteria.

1.

6Delivery,StorageandHandling1.

6.

1Delivermaterialstotheprojectinmanufacturer'sunopenedpackages,fullyidentifiedastotradename,typeandotheridentifyingdata.

PackagingshallbeartheULandULClabelsforfirehazardandfire-resist-anceclassifications.

1.

6.

2Storematerialsaboveground,inadrylocation,protectedfromtheweather.

Damagedpackagesfoundunsuitableforuseshouldberejectedandremovedfromtheproject.

1.

7ProjectConditions1.

7.

1Whentheprevailingoutdoortemperatureatthebuild-ingislessthan40°F(4°C),aminimumsubstrateandambienttemperatureof40°F(4°C)shallbemaintainedpriorto,during,andaminimumof24hoursafterapplicationofspray-appliedfireresis-tivematerial.

IfnecessaryforjobprogressGeneralContractorshallprovideenclosuresandheattomain-tainpropertemperaturesandhumiditylevels.

1.

7.

2GeneralContractorshallprovideventilationtoallowproperdryingofthespray-appliedfireresistivematerialduringandsubsequenttoitsapplication.

1.

7.

2.

1Inenclosedareasventilationshallnotbelessthan4completeairchangesperhour.

1.

8Sequencing/Scheduling1.

8.

1Allfireprotectionworkonafloorshallbecompletedbeforeproceedingtothenextfloor.

1.

8.

2TheContractorshallcooperateinthecoordinationandschedulingoffireprotectionworktoavoiddelaysinjobprogress.

PART2–PRODUCTS2.

1AcceptableManufacturers.

Thespray-appliedfireresistivematerialshallbemanufacturedundertheCAFCObrandname,byauthorizedproducers.

2.

2Materials2.

2.

1MaterialsshallbeBLAZE-SHIELDHP,(UL/ULCdesignation:TypeHP)appliedtoconformtothedrawings,specificationsandfollowingtestcriteria:2.

2.

1.

1Deflection:WhentestedinaccordancewithASTME759,thematerialshallnotcrackordelaminatewhenthenon-concretetoppedgalvanizeddecktowhichitisappliedissubjectedtoaonetimeverticalcenterloadresultinginadownwarddeflectionof1/120thofthespan.

2.

2.

1.

2BondImpact:WhentestedinaccordancewithASTME760,thematerialshallnotcrackordelaminatefromtheconcretetoppedgalvanizeddecktowhichitisapplied.

2.

2.

1.

3Cohesion/Adhesion(bondstrength):WhentestedinaccordancewithASTME736,thematerialappliedoveruncoatedorgalvanizedsteelshallhaveanaveragebondstrengthof434psf(20.

8kPa).

2.

2.

1.

4AirErosion:WhentestedinaccordancewithASTME859,thematerialshallnotbesubjecttolossesfromthefinishedapplicationgreaterthan0.

025gramspersq.

ft.

(0.

27gramspersquaremeter).

2.

2.

1.

5CompressiveStrength:WhentestedinaccordancewithASTME761,thematerialshallnotdeformmorethan10percentwhensubjectedtoacrushingforceof7,344psf(351kPa).

2.

2.

1.

6CorrosionResistance:WhentestedinaccordancewithASTME937,thematerialshallnotpromotecorrosionofsteel.

2.

2.

1.

7Noncombustibility:WhentestedinaccordancewithASTME136orCAN4-S114,thematerialshallbenon-combustible.

2.

2.

1.

8SurfaceBurningCharacteristics:WhentestedinaccordancewithASTME84orCAN/ULC-S102,thematerialshallexhibitthefollowingsurfaceburningcharacteristics:FlameSpread.

0SmokeDeveloped.

.

.

.

.

02.

2.

1.

9Density:WhentestedinaccordancewithASTME605,thematerialshallmeettheminimumindividualandaveragedensityvaluesaslistedintheappropriateUL/ULCdesignorasrequiredbytheauthorityhavingjurisdiction.

2.

2.

2ThematerialshallhavebeentestedandclassifiedbyUnderwritersLaboratories,Inc.

(UL)orUnderwritersLaboratoriesofCanada(ULC)inaccordancewiththeproceduresofUL263(ASTME119)orCAN/ULC-S101.

2.

2.

3Spray-appliedfireresistivematerialsshallbeappliedattheapprovedminimumthicknessanddensitytoachievethefollowingratings:Floorassemblies___hr.

Roofassemblies___hr.

Beams___hr.

Girders___hr.

Columns___hr.

Joists___hr.

2.

2.

4Potablewatershallbeusedfortheapplicationofspray-appliedfireresistivematerials.

2.

2.

5Spray-appliedfireresistivematerialsshallcontainnodetectableasbestos.

PART3–EXECUTION3.

1Preparation3.

1.

1Allsurfacestoreceivefireprotectionshallbefreeofoil,grease,loosemillscale,dirt,paints/primersorotherforeignmaterialswhichwouldimpairsatisfacto-rybondingtothesurface.

Manufacturershallbecon-tactedforproceduresonhandlingprimed/paintedsteel.

Anycleaningofsurfacestoreceivespray-appliedfireresistivematerialshallbetheresponsibili-tyoftheGeneralContractororSteelErector,asout-linedinthestructuralsteelorsteeldecksection.

3.

1.

2Clips,hangers,supports,sleevesandotherattach-mentstothesubstratearetobeplacedbyotherspriortotheapplicationofspray-appliedfireresistivemate-rials.

3.

1.

3Theinstallationofducts,piping,conduitorothersuspendedequipmentshallnottakeplaceuntiltheapplicationofspray-appliedfireresistivematerialiscompleteinanarea.

3.

1.

4Thespray-appliedfireresistivematerialshallonlybeappliedtosteeldeckwhichhasbeenfabricatedanderectedinaccordancewiththecriteriasetbytheSteelDeckInstitute.

3.

1.

5Whenrooftrafficisanticipated,asinthecaseofperi-odicmaintenance,roofingpaversshallbeinstalledasawalkwaytodistributeloads.

3.

2Application3.

2.

1Equipment,mixingandapplicationshallbeinaccordancewiththemanufacturer'swrittenapplicationinstructions.

3.

2.

2Theapplicationofspray-appliedfireresistivematerialshallnotcommenceuntilcertificationhasbeenreceivedbytheGeneralContractorthatsurfacestoreceivespray-appliedfireresistivemateri-alhavebeeninspectedbytheapplicatorandareacceptabletoreceivespray-appliedfireresistivematerial.

3.

2.

3AllunsuitablesubstratesmustbeidentifiedandmadeknowntotheGeneralContractorandcorrectedpriortoapplicationofthespray-appliedfireresistivematerial.

3.

2.

4Spray-appliedfireresistivematerialshallnotbeappliedtosteelfloordeckspriortothecompletionofconcreteworkonthatdeck.

3.

2.

5Theapplicationofspray-appliedfireresistivematerialtotheundersideofroofdeckshallnotcommenceuntiltheroofingiscompletelyinstalledandtight,allpenthousesarecomplete,allmechanicalunitshavebeenplaced,andafterconstructionrooftraffichasceased.

3.

2.

6Propertemperatureandventilationshallbemaintainedasspecifiedin1.

7.

1,1.

7.

2and1.

7.

2.

1.

3.

2.

7Providemasking,dropclothsorothersuitablecoveringstopreventoversprayfromcomingincontactwithsurfacesnotintendedtobesprayed.

3.

2.

8CAFCOBOND-SEAL(TypeEBS)adhesiveshallbeappliedaspertheappropriateUL/ULCfireresistancedesignandmanufacturer'swrittenrecommendations.

3.

3RepairingandCleaning3.

3.

1Allpatchingofandrepairtospray-appliedfireresis-tivematerial,duetodamagebyothertrades,shallbeperformedunderthissectionandpaidforbythetraderesponsibleforthedamage.

3.

3.

2Afterthecompletionoftheworkinthissection,equipmentshallberemovedandallsurfacesnottobesprayedshallbecleanedtotheextentpreviouslyagreedtobytheapplicatorandGeneralContractor.

3.

4InspectionandTesting3.

4.

1Thespray-appliedfireresistivematerialshallbetestedforthicknessanddensityinaccordancewithoneofthefollowingprocedures:ASTME605-StandardTestMethodofSprayedFire-ResistiveMaterialsAppliedtoStructuralMembers.

AWCI-TechnicalManual12-AStandardPracticefortheTestingandInspectionofFieldAppliedSprayedFire-ResistiveMaterialsanAnnotatedGuide.

UBCStandardNo.

7-6-ThicknessandDensityDeterminationforSpray-AppliedFireProtection.

ProductAvailabilityIsolatekInternationalSpray-AppliedFireResistiveMaterialsareavailabletotrained,licensedcontractorsaroundtheworldfromstrategicallylocatedproductionanddistributionpointsintheU.

S.

,Canada,Mexico,EuropeandthePacificBasin.

ISOLATEKINTERNATIONALisregisteredwiththeAIAContinuingEducationSystem(AIA/CES)ForFurtherInformationCAFCOTechnicalandSalesRepresentativesarealwaysavailabletolendassistance.

Additionalprintedmaterials,includingMaterialSafetyDataSheets,andotherproductliterature,areavailableuponrequest.

FormoreinformationaboutourCAFCOlineofsprayedfireprotection,thermalandacousticaltreatments,IntumescentCoatings,thermalbarriersandCAFCO-BOARDorforthenameoftheSalesRepresentativeinyourarea,pleasecontact:Formoredetailedproductinformation,visitourwebsiteatwww.

cafco.

comorcontactusattechnical@isolatek.

comTheperformancedatahereinreflectourexpectationsbasedontestsconductedinaccordancewithrecognizedstandardmethodsundercontrolledconditions.

Theapplicator,generalcontractor,propertyownerand/oruserMUSTread,understandandfollowthedirections,specificationsand/orrecommendationssetforthinIsolatekInternational'spublicationsconcerninguseandapplicationoftheseproducts,andshouldnotrelymerelyontheinformationcontainedinthisproductdatasheet.

IsolatekInternationalisnotresponsibleforpropertydamage,bodilyinjuries,consequentialdamages,orlossesofanykindthatarisefromorarerelatedtotheapplicator's,generalcontractor's,orpropertyowner'sfailuretofollowtherecommendationssetforthinIsolatekInternational'spublications.

ThesaleoftheseproductsshallbesubjecttotheTermsandConditionsofSalesetforthintheCompany'sinvoices.

IntheUnitedStates:IsolatekInternational,Stanhope,NewJerseyTel:800.

631.

9600Fax:973.

347.

9170InMexico&CentralAmerica:CafcoMexicoS.

A.

deC.

V.

,MexicoD.

F.

Tel:525.

254.

6683Fax:525.

531.

7826InAndeanCountries:CafcoAndinaS.

A.

,Santiago,ChileTel:562.

719.

0394InCanada:CafcoIndustries,Toronto(Ontario)Tel:888.

873.

0003Fax:416.

679.

2933InAsia/Pacfic:Tel:60.

3.

5121.

3886Fax:60.

3.

5121.

4886TotalPassiveFireProtectionISOLATEKInternationalAllRightsReserved9/11

- Assembliesblaze相关文档

- 请浏览网站获取更多信息:www.memblaze.com

- hitblaze

- averageblaze

- Ellefsenblaze

- 系列blaze

- platformsblaze

HostKvm($4.25/月)俄罗斯/香港高防VPS

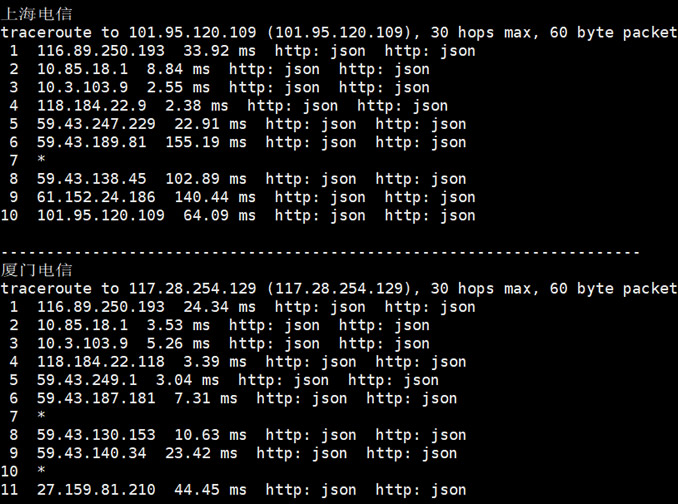

HostKvm又上新了,这次上架了2个线路产品:俄罗斯和香港高防VPS,其中俄罗斯经测试电信CN2线路,而香港高防VPS提供30Gbps攻击防御。HostKvm是一家成立于2013年的国外主机服务商,主要提供基于KVM架构的VPS主机,可选数据中心包括日本、新加坡、韩国、美国、中国香港等多个地区机房,均为国内直连或优化线路,延迟较低,适合建站或者远程办公等。俄罗斯VPSCPU:1core内存:2G...

ParkinHost:俄罗斯离岸主机,抗投诉VPS,200Mbps带宽/莫斯科CN2线路/不限流量/无视DMCA/55折促销26.4欧元 /年起

外贸主机哪家好?抗投诉VPS哪家好?无视DMCA。ParkinHost今年还没有搞过促销,这次parkinhost俄罗斯机房上新服务器,母机采用2个E5-2680v3处理器、128G内存、RAID10硬盘、2Gbps上行线路。具体到VPS全部200Mbps带宽,除了最便宜的套餐限制流量之外,其他的全部是无限流量VPS。ParkinHost,成立于 2013 年,印度主机商,隶属于 DiggDigi...

香港2GB内存DIYVM2核(¥50月)香港沙田CN2云服务器

DiyVM 香港沙田机房,也是采用的CN2优化线路,目前也有入手且在使用中,我个人感觉如果中文业务需要用到的话虽然日本机房也是CN2,但是线路的稳定性不如香港机房,所以我们在这篇文章中亲测看看香港机房,然后对比之前看到的日本机房。香港机房的配置信息。CPU内存 硬盘带宽IP价格购买地址2核2G50G2M1¥50/月选择方案4核4G60G3M1¥100/月选择方案4核8G70G3M4¥200/月选择...

blaze为你推荐

-

虚拟主机什么是虚拟主机?域名空间什么是空间 什么是域名广东虚拟主机有什么便宜又好用的虚拟主机吗?免费国内空间谁知道国内哪个免费空间好,要1GB的网站域名域名和网址有什么区别?网站服务器租用哪些网站适合独立服务器租用?价格方面怎么样?网站服务器租用网站服务器租用网站服务器租用个人网站服务器租用一年多少钱域名主机域名,主机空间和网站文件三者之间的区别是什么域名主机域名和主机IP地址有什么关系